Horizontal gas well liquid holdup calculation method based on flow pattern conversion limit

A calculation method and liquid holdup technology, applied in calculation, computer-aided design, earthwork drilling and production, etc., can solve the problems of large differences in experimental conditions of flow patterns, lack of simplicity and practicality, poor engineering applicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

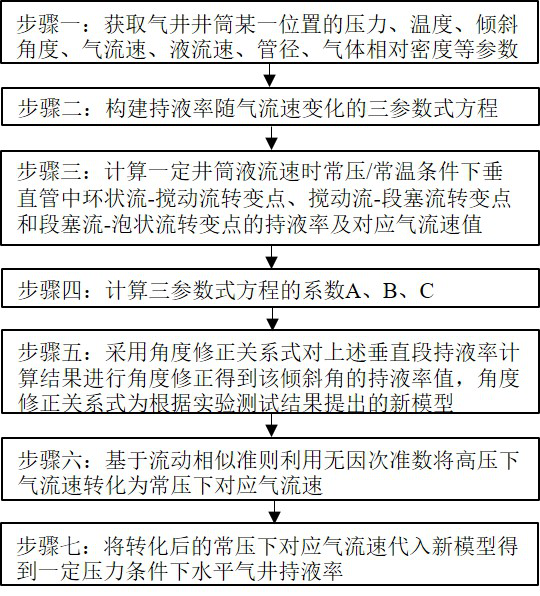

[0069] In order to make the objectives, technical solutions and advantages of the present invention clearer and clearer, the present invention is further described in a complete and comprehensive manner below.

[0070] First, obtain parameters such as pressure, temperature, inclination angle, gas flow rate, liquid flow rate, pipe diameter, and gas relative density at a certain position in the wellbore of the gas well;

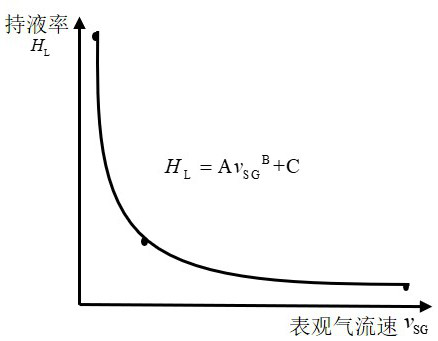

[0071] Step 2: Construct a three-parameter equation according to the change trend of liquid holdup with gas flow rate:

[0072] H L =Av SG B +C (1)

[0073] In the formula, H L is the vertical liquid holdup, dimensionless; v SG is the apparent gas velocity, m / s; A, B, and C are all model coefficients, dimensionless.

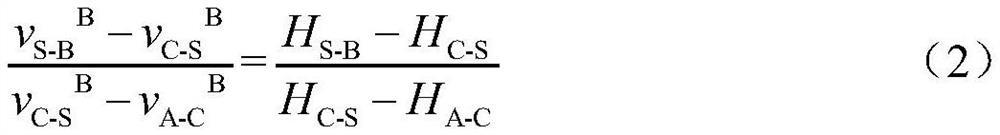

[0074] Step 3: Calculate the annular flow-stirring flow transition point, agitation flow-slug flow transition point and slug flow-bubble transition point in the vertical pipe under normal pressure / normal temperature conditions (0.1MPa, 20°C)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com