Simulation fault motion matching type box body structure and seismic fault simulation experiment platform

A box structure and motion technology, applied in the testing of machines/structural components, teaching models, instruments, etc., can solve the problems of waste, inability to realize tailoring, time-consuming and labor-intensive, and achieve the effect of flexible construction and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

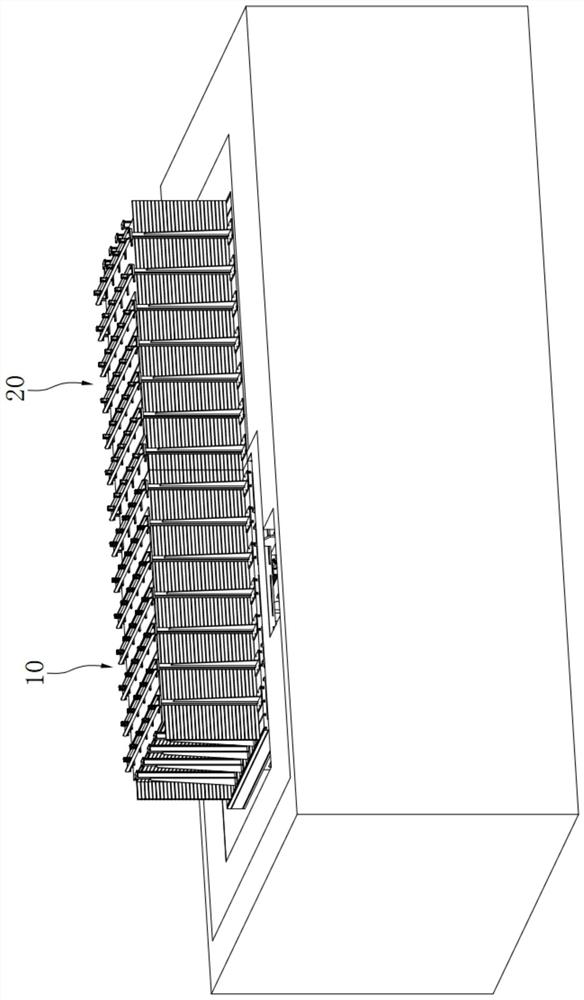

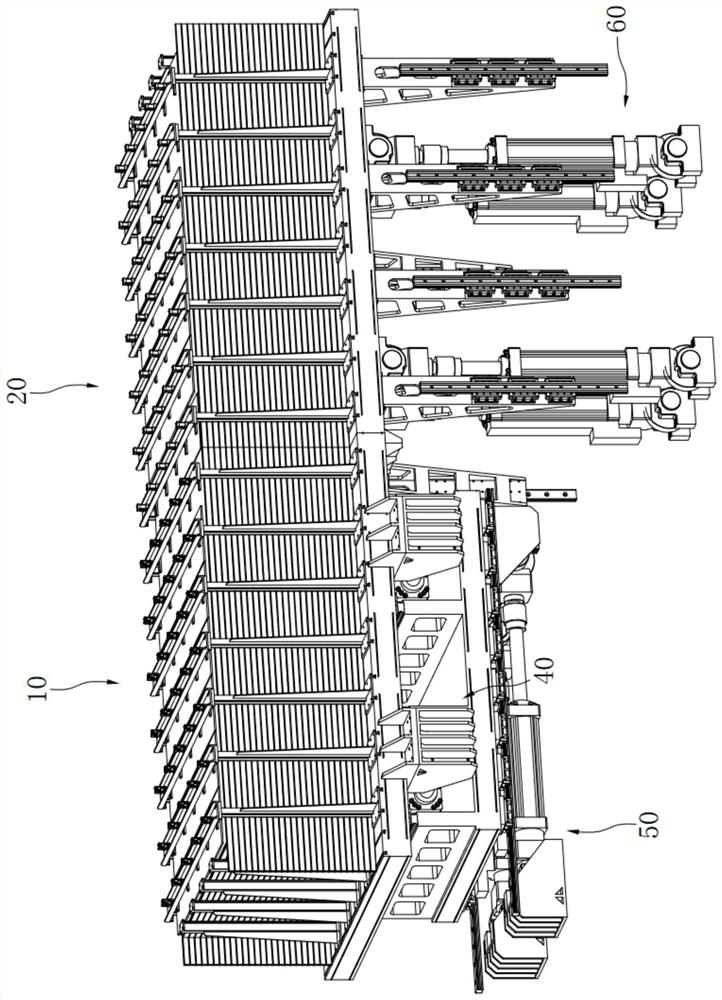

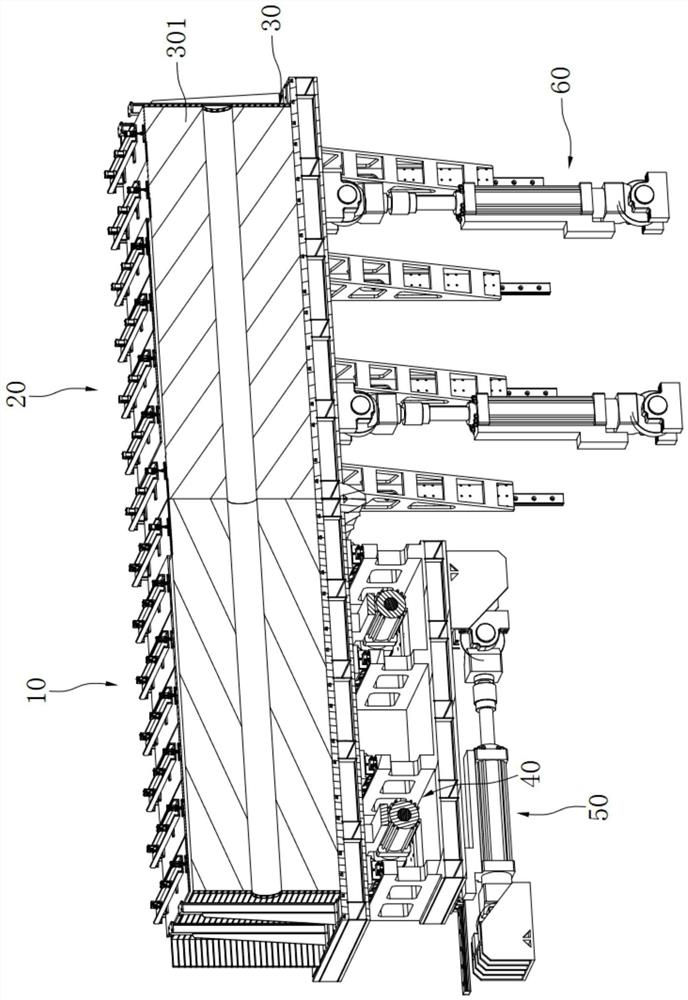

[0060] like Figure 1 to Figure 3 As shown, it is the first preferred embodiment of the seismic fault simulation experimental platform of the present invention. The seismic fault simulation experiment platform includes a left box body 10 , a right box body 20 , a first driving mechanism 40 , a second driving mechanism 50 and a third driving mechanism 60 .

[0061] Wherein, the right side of the left box 10 has an opening, and the left side of the right box 20 has an opening. After the left and right are arranged in a coordinated manner, the left box 10 and the right box 20 form a matching box structure, and the inner cavities of the two are connected. A accommodating cavity 30 for accommodating the soil layer 301 is formed.

[0062] Specifically, as figure 2 As shown, the left box body 10 and the right box body 20 both include a main box body 1 , an end cover 2 and a pressurizing device 4 . The main box 1 has openings on both sides along the left and right directions, and ...

Embodiment 2

[0070] like Figures 4 to 11 As shown, it is the second preferred embodiment of the seismic fault simulation experimental platform of the present invention. The difference from Example 1 is:

[0071] In this embodiment, as Figure 4 and Figure 5 As shown, an adjustable box 3 is installed on the other side of the main box 1, and the side edge of the adjustable box 3 facing the side of the main box 1 is detachably connected with the side edge of the other side of the main box 1, The side edge of the adjustable box body 3 facing away from the main box body 1 is bent outward to form a second convex edge 31. The second convex edge 31 of the adjustable box body 3 on the left box body 10 can be opposite to the right box body. The second convex edge 31 of the adjustable box body 3 on the body 20 moves and is always in close contact with the second convex edge 31 of the adjustable box body 3 on the right box body 20 .

[0072] Denote the angle between the contact surface and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com