Contact improved test head between contact probe and guide hole

A technology of test head and guide hole, which is applied in the field of test head, can solve the problems of frequency performance limitation of test head, impossible to ensure effective electrical connection between probe and metallized part, and overall performance limitation of test head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

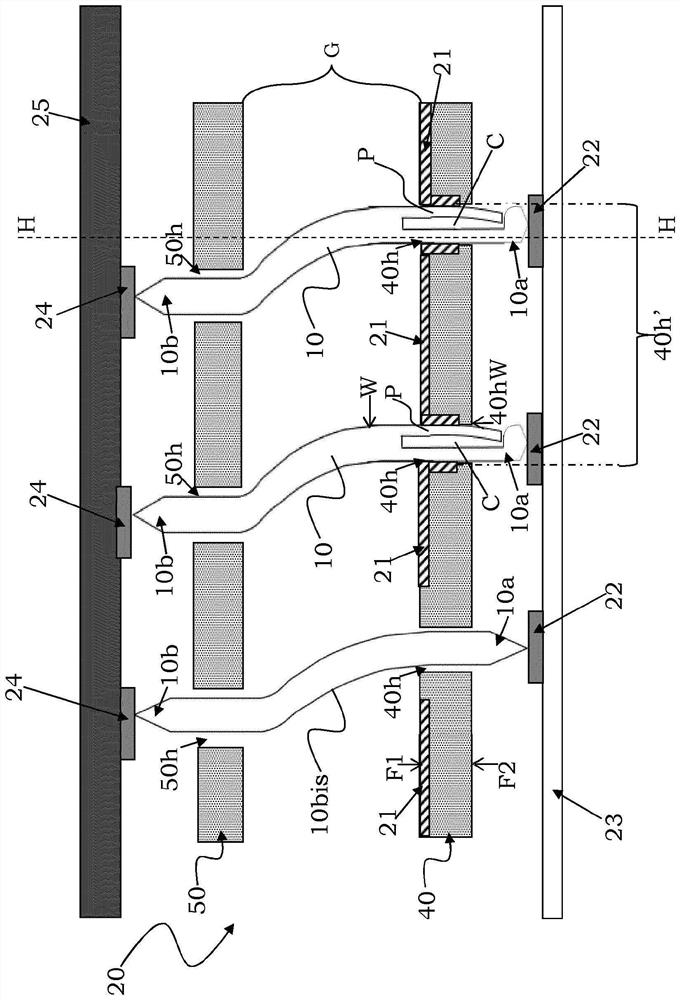

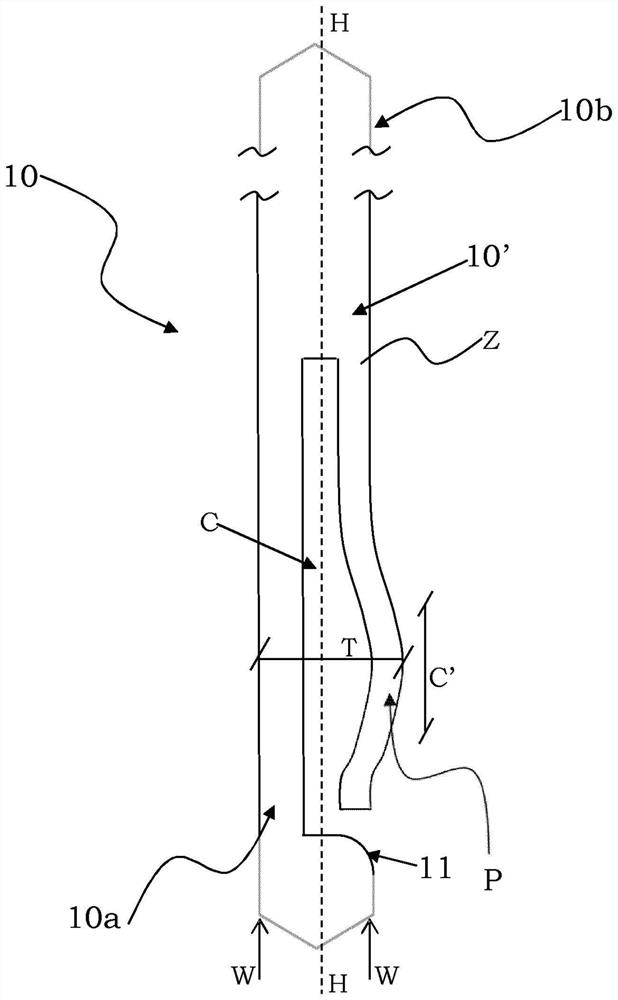

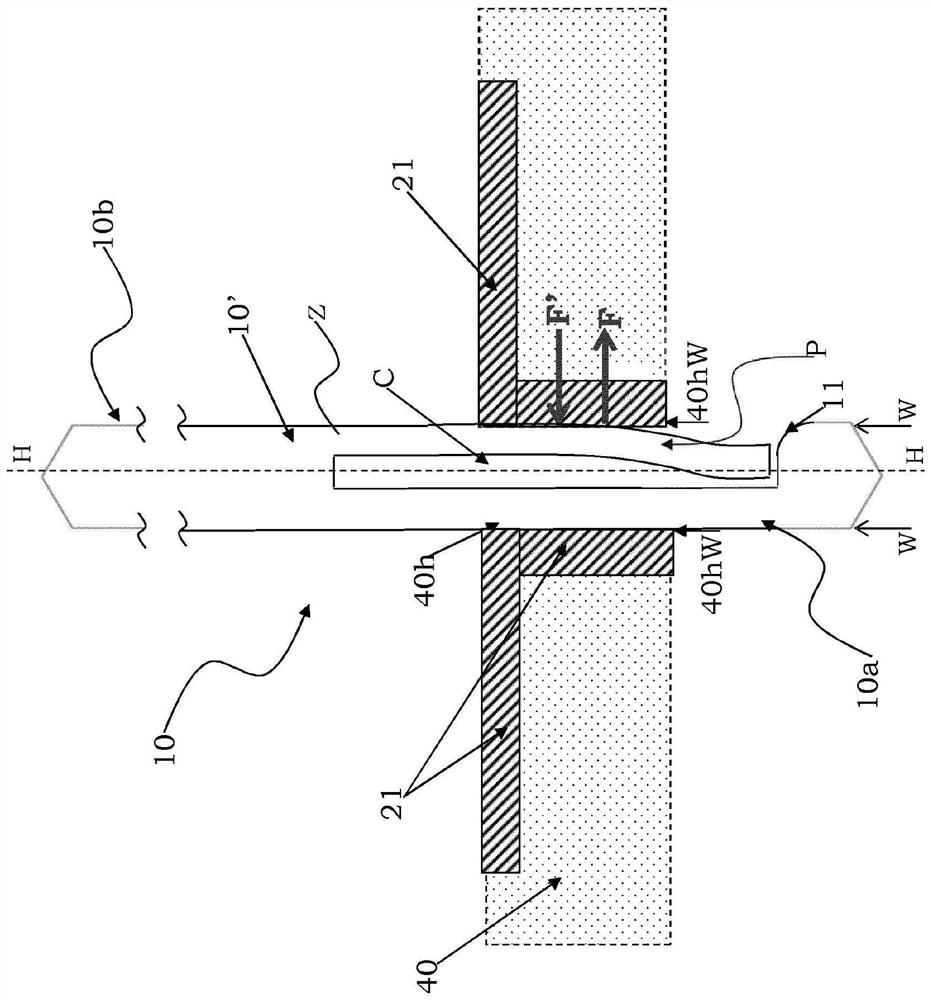

[0036] With reference to these drawings, especially figure 1 An example of a test head according to the invention is generally indicated schematically at 20 .

[0037] Notably, the figures are schematic and not to scale, but are drawn to emphasize important features of the invention. Furthermore, in the drawings, various elements are depicted schematically, the shapes of which vary depending on the desired application. It should also be noted that in the figures, the same reference numbers refer to elements that are identical in shape or function. Finally, certain features described in relation to the embodiments shown in the figures also apply to other embodiments shown in other figures.

[0038] The test head 20 is adapted to be connected to equipment (not shown) for testing electronic devices (eg high frequency devices) integrated on the semiconductor wafer 23 .

[0039] The test head 20 includes a plurality of contact probes 10 slidably received in the test head for con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com