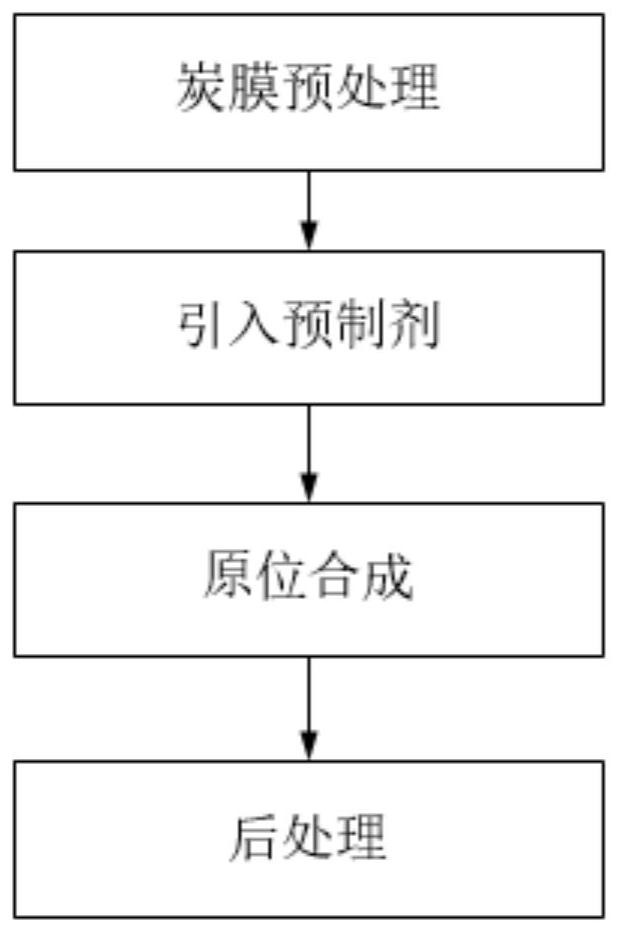

In-situ synthesis method for regulating and controlling surface and interface pores and properties of carbon membrane

An in-situ synthesis, surface interface technology, applied in membrane technology, separation methods, semi-permeable membrane separation, etc., can solve the problems of poor pore structure and surface properties of carbon membranes, poor separation performance of carbon membranes for oily wastewater purification and treatment, etc. Achieve the effect of improving surface hydrophilicity, easy to enlarge and popularize application, and concentrated pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

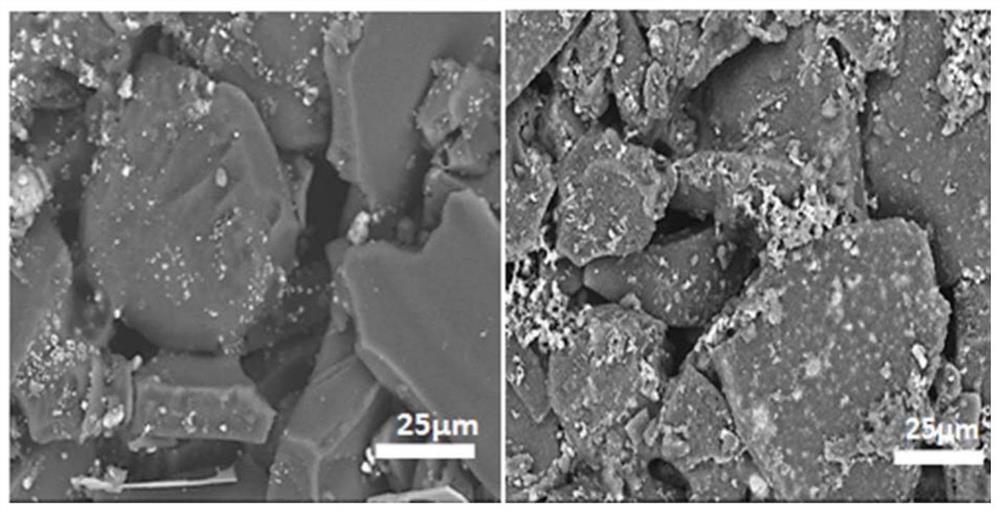

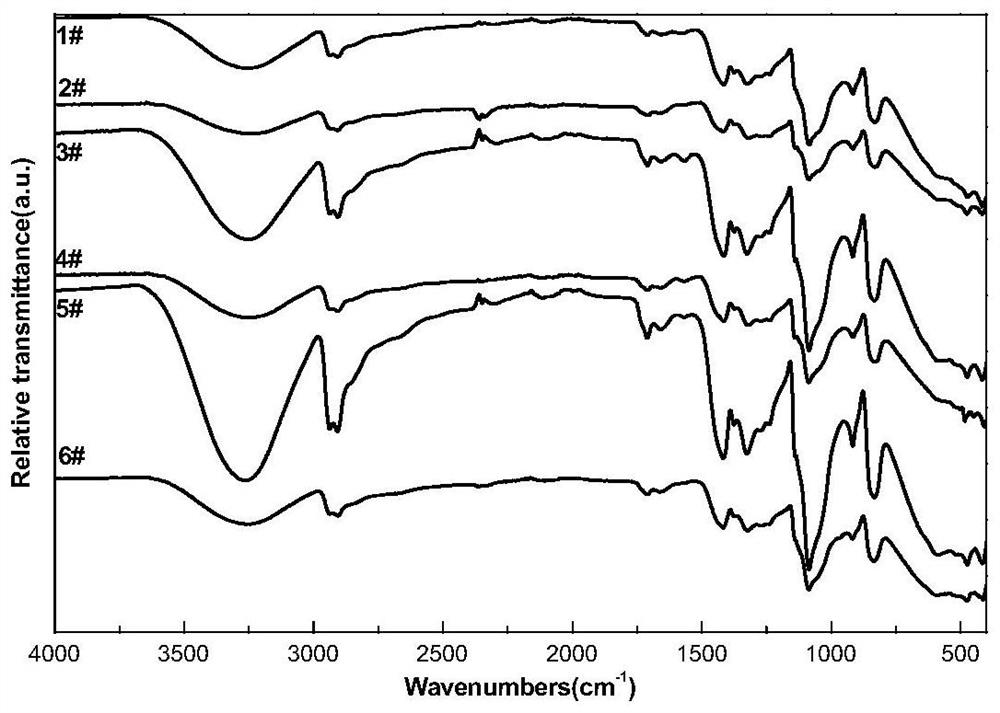

[0038] In the present invention, the carbon membrane with an average pore diameter of 2 μm, a porosity of 70% and a surface water contact angle of 60° is placed in an oven at 100° C. for 10 hours to reach a constant weight; then, degassing is continued in a vacuum oven at 100° C. for 2 hours. . Add hydrochloric acid dropwise to the prepared tromethamine solution with a concentration of 1.2 g / L, and adjust the pH to 8.56. Dopamine is then added to prepare a pre-formulation with a concentration of 3-10 mg / L. Wherein, hydrochloric acid: tromethamine: dopamine=0.217: 1.21: 0.003-0.01 (mass ratio). The carbon film is dipped into the preformulation solution, and the reaction temperature is 25-50° C. for 1-72 hours. After repeating the introduction reaction, the carbon membrane was taken out, washed once with distilled water, and then air-dried at room temperature for 30 minutes in a natural environment. The osmosis method was used to determine the separation effect of the carbon ...

Embodiment 2

[0042] First, the carbon membrane with an average pore size of 0.1 μm, a porosity of 20%, and a surface water contact angle of 150° was dried in an oven at 100°C for 10 hours to reach a constant weight; then, degassed in a vacuum oven at 100°C. 6h. A glutaraldehyde-hydrochloric acid mixed solution is prepared, and then polyvinyl alcohol is added to obtain a preformulation solution. Wherein, glutaraldehyde: hydrochloric acid: polyvinyl alcohol=3-13:2.5-10:5-20 (mass ratio). The carbon film is dipped into the preformulation solution, and the reaction temperature is 40-60° C. for 0.1-4 hours. After repeating the introduction reaction, the carbon membrane was taken out, washed 5 times with low-concentration sodium hydroxide lye with pH 9-12 and distilled water to neutrality, and then dried in argon flow at room temperature under natural environment for 300 minutes. The osmosis method was used to determine the separation effect of carbon membranes on oily wastewater. The specific...

Embodiment 3

[0046] First, the carbon membrane with an average pore size of 0.6 μm, a porosity of 50%, and a surface water contact angle of 110° was dried in an oven at 100°C for 10 hours to reach a constant weight; then, degassed in a vacuum oven at 100°C. 4h. Prepare ferric chloride and sodium hydroxide solution, mix the two solutions evenly to prepare a pre-formulation solution. Wherein, ferric chloride: sodium hydroxide=1:1 (mass ratio). The carbon film is immersed in the preformulation solution, and the reaction temperature is 40-60° C. for 0.1-10 hours. After repeating the introduction reaction, the carbon membrane was taken out, washed 20 times with low-concentration dilute hydrochloric acid and distilled water with a pH value of 1-3 until neutral, and then dried in hot air at 60°C for 180 minutes in a natural environment. The osmosis method was used to determine the separation effect of the carbon membrane on the oily wastewater. The specific data are shown in Table 3.

[0047] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com