A device and method for detecting gas content in liquid metal

A liquid metal and gas content technology, applied in the direction of measuring devices, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve the problems of not being able to reflect the change of liquid metal gas content in time, long response time of gas alarm devices, etc., to achieve Good linearity and range, high magnetic field stability, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

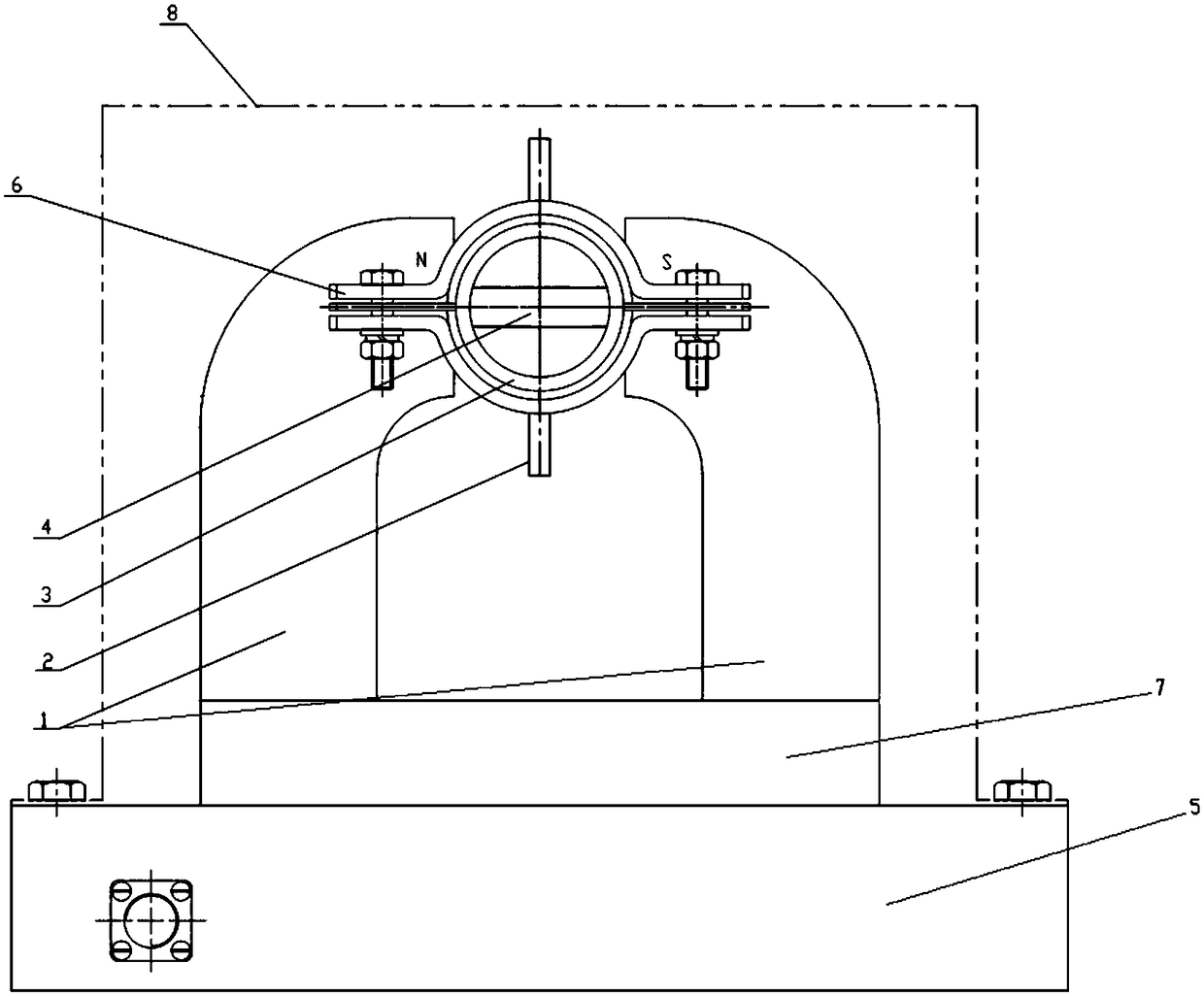

[0030] A device for detecting gas content in liquid metal, the device includes a primary sensor and a secondary instrument, wherein the primary sensor includes a magnetic steel assembly, a pipeline assembly 3, a turbulence generator 4, an electrode 2, and a supporting positioning assembly 5;

[0031] The two ends of the pipeline assembly 3 are respectively communicated with the liquid metal pipeline to be detected through the interface;

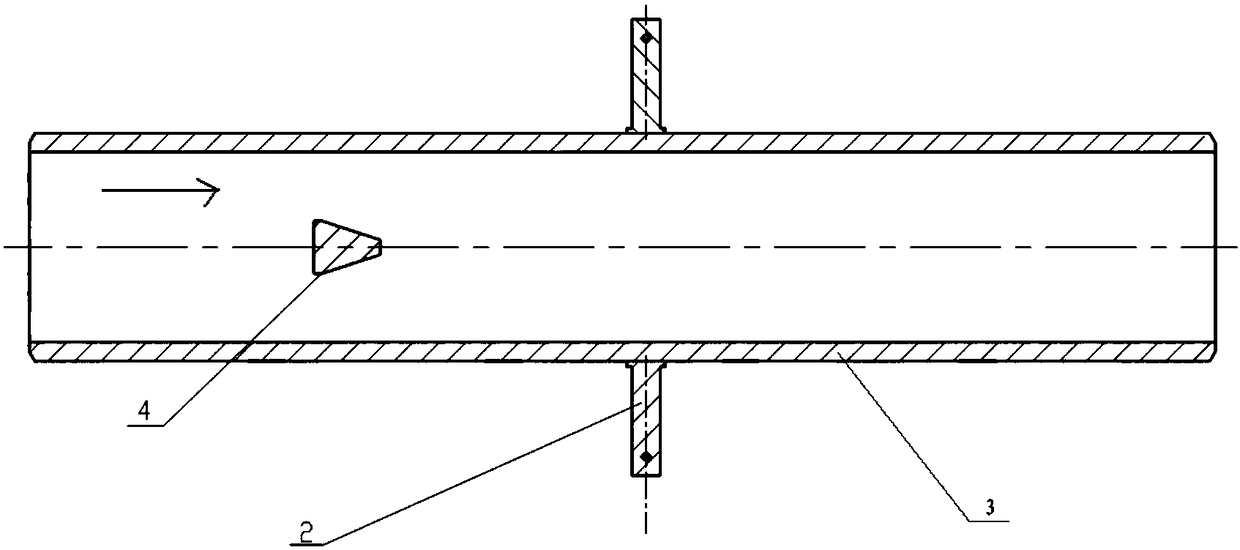

[0032] The turbulence generator 4 is located in the pipeline assembly, and the turbulence generator 4 causes the fluid in the pipeline assembly 3 to generate eddy currents, increasing the signal fluctuation amplitude; the turbulence generator 4 is a wedge-shaped polyhedron structure, and it is located in the pipeline assembly 3 The radial center position of the turbulent flow generator 4 is placed so that the liquid metal first flows through the wide surface of the wedge-shaped polyhedron structure, and then flows through the narrow surface of...

Embodiment 2

[0040] The difference from Example 1 is that the liquid metal is sodium, and the number of electrodes is 2 pairs. There is an air gap of 1 mm between the pipe assembly and the two horn-shaped permanent magnets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com