Device for equally dividing pulp water in papermaking headbox

A headbox and slurry water technology, which is applied to mixers with rotary stirring devices, paper recycling, transportation and packaging, can solve problems such as difficult cleaning, affecting processing efficiency, and difficult disassembly and assembly, and achieves good automation effects. , Improve work efficiency and facilitate the effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical solutions of the present invention, the following specific embodiments are described in detail.

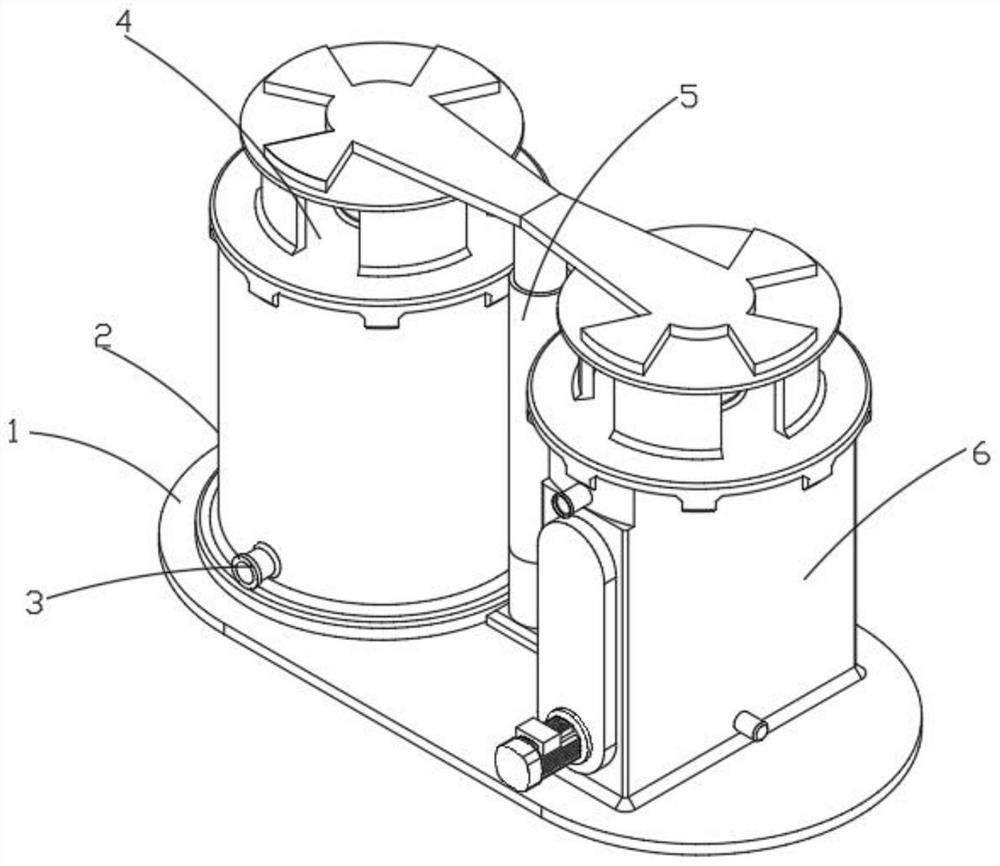

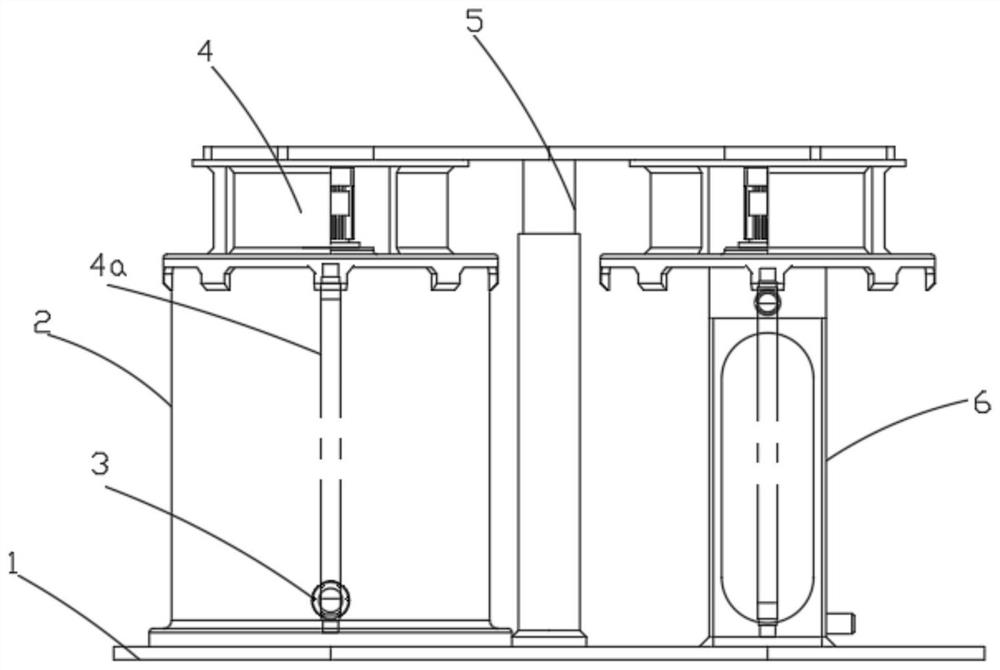

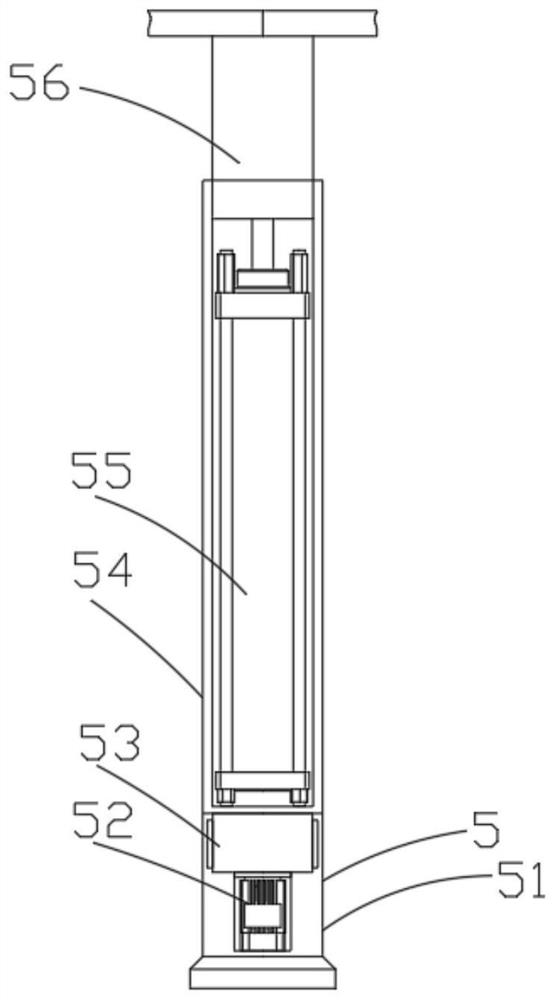

[0034] see figure 1 and figure 2 , the present invention provides a device for equalizing the pulp and water in a papermaking headbox, comprising a base plate 1, a papermaking headbox 2 is fixed at the top left end of the base plate 1, and a lead box 2 that communicates with it is installed at the lower end of the front end of the papermaking headbox 2 Pipe 3, the outlet pipe 3 can export the slurry water, the top of the papermaking headbox 2 is provided with a toggle device 4, the toggle device 4 is provided with two groups, and the left upper end of the other group of toggle devices 4 is merged with it. The bottom of the two sets of toggle devices 4 is connected to the adjustment device 5. The adjustment device 5 can realize the adjustment of the height and the angle position of the toggle device 4. The bottom of the adjustment ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap