System and method for filament separation and quality evaluation

A technology for quality evaluation and filaments, applied in the field of separation and detection, can solve the problems of low efficiency, time-consuming, and difficulty in identifying clumps of filaments such as shredded tobacco, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

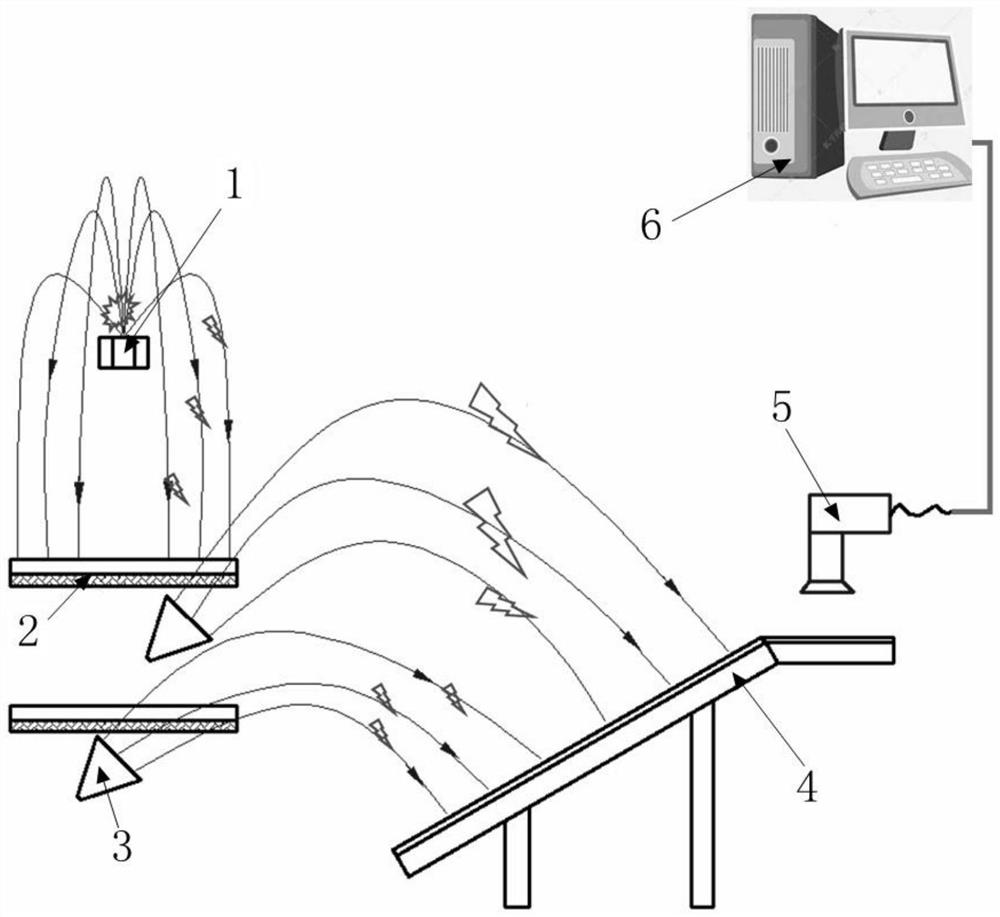

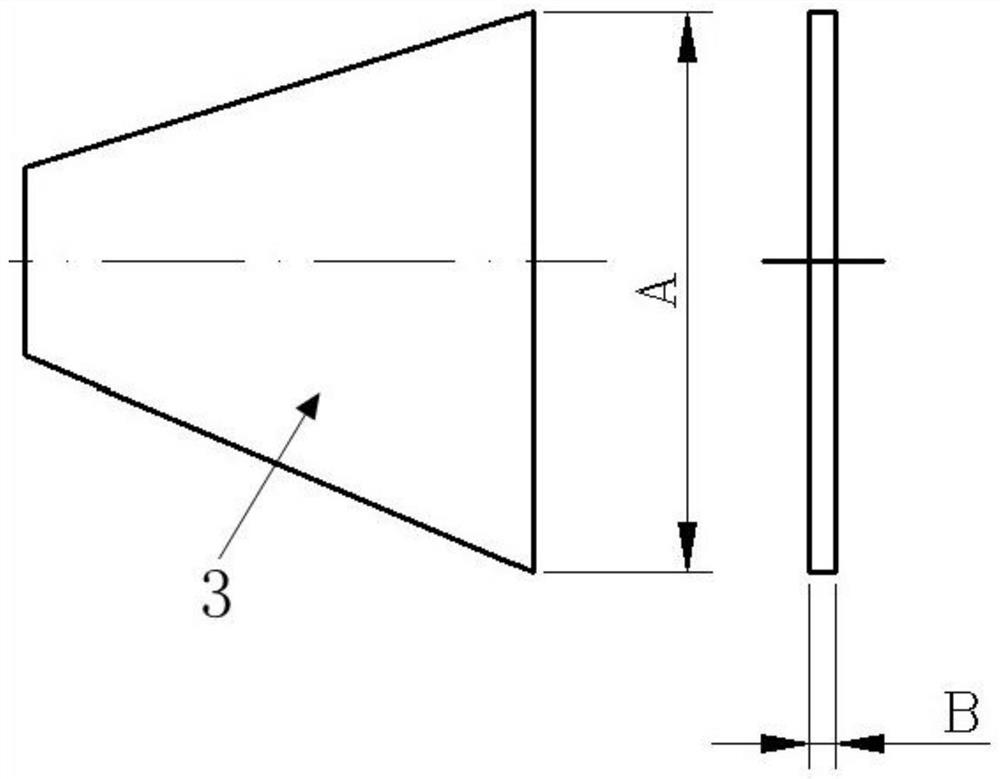

[0030] like figure 1 As shown, a system for separation and quality evaluation of filaments includes an air ejector 1, a sieve tray 2, a slotted airflow disperser 3 and a conveyor belt 4, and the two sieve trays 2 are layered sequentially from top to bottom Arrangement, and the sieving aperture of the upper sieve tray 2 is greater than the sieving aperture of the lower sieve tray 2, and each described sieve tray 2 is provided with a gap air diffuser 3, and the gap centerline of the gap air diffuser 3 and The plane of the sieve tray 2 is a projection angle, and the projection angle is an acute angle. The filaments on top move parabolically and settle to different areas on the conveyor belt 4 .

[0031] Also includes a camera 5 and a machine vision analysis module 6, the camera 5 is located above the conveyor belt 4 and is aimed at the conveying surface of the conveyor belt 4, and the machine vision analysis module 6 is used to identify the characteristics of the filaments and ...

Embodiment 2

[0037] A method for filament separation and quality evaluation, the method is realized by a system for filament separation and quality evaluation described in Embodiment 1, and specifically includes the following steps:

[0038] S1, airflow impact and throwing: use the airflow ejected from the air jet 1 to impact upward and dissociate the filamentous mass, and the dissociated filamentous mass is dispersed downwards and outwards;

[0039]S2. Vibration classification of sieve tray 2: the filaments are scattered on the sieve tray 2 of the uppermost layer, and under the action of vibration force, sieve from the sieve tray 2 of the uppermost layer to the sieve tray 2 of the lowermost layer step by step, Complete the classification of the filaments from large to small; wherein, the sieve tray 2 of the lowermost layer does not vibrate;

[0040] S3. Air dispersion in the gap: in the order from top to bottom, each air diffuser 3 in the gap blows up the filaments in the sieve tray 2 loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com