Machining method of double-spiral groove

A processing method, double-helix technology, applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reducing the precision of spiral groove processing, high labor intensity, low degree of automation, etc., to improve stability and accuracy High performance, wide range of processing adaptation, and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

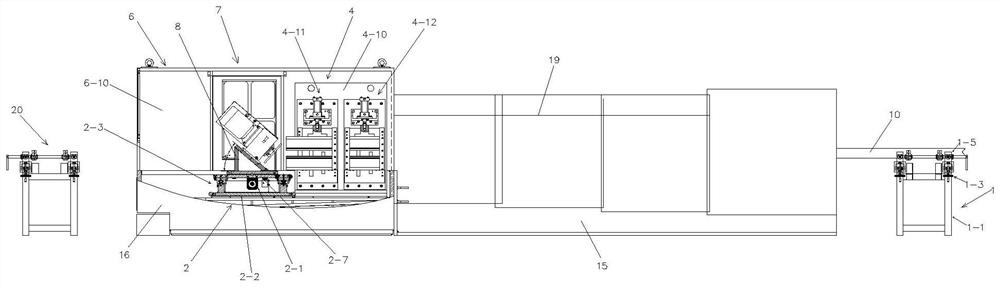

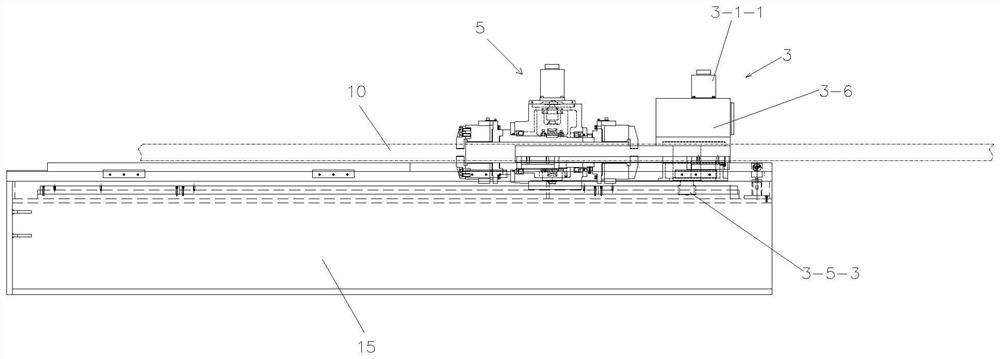

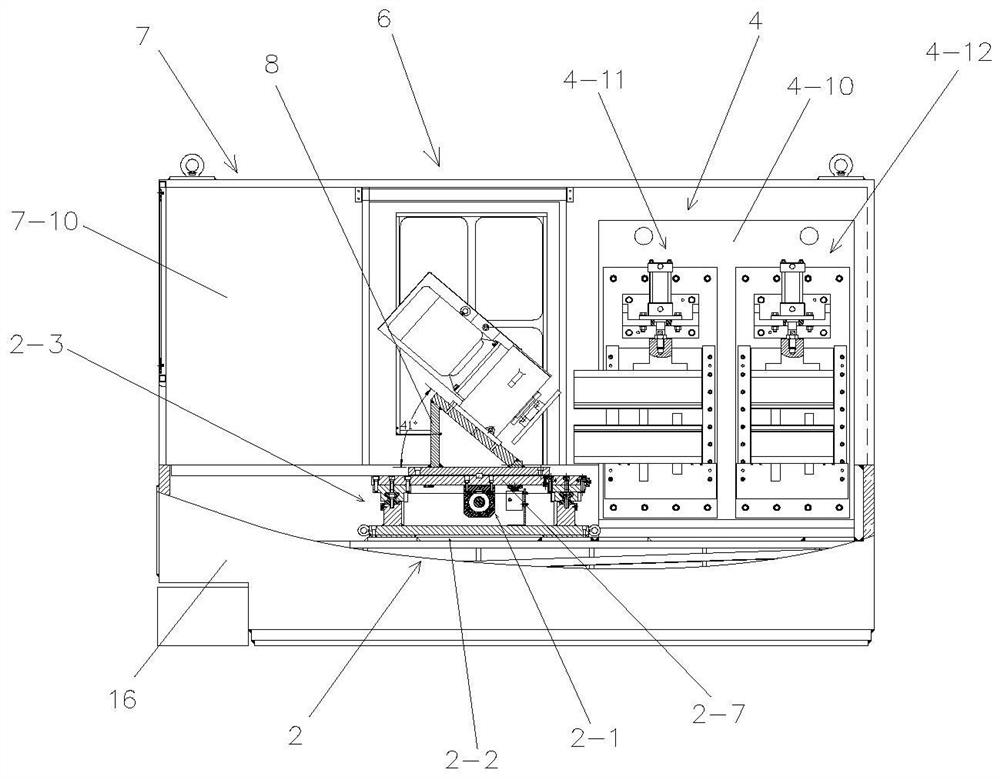

[0182] like Figure 1 to Figure 12 As shown, the device used in the method of the present invention includes a double helical groove machining bed, a loading rack 1 arranged at the loading end of the double helical groove machining bed and feeding the workpiece 10, and a loading rack 1 disposed on the double helical groove machining bed. The discharge end of the groove machining machine and the unloading rack 20 for holding the workpiece after machining. The double-spiral groove machining machine includes a head milling cutter structure and a body rotary feed structure. The head milling cutter structure includes a machine tool. A head 16 , a milling cutter mechanism disposed on the machine head 16 and processing the workpiece 10 , and a front clamping member disposed on the machine head 16 on the feed side of the milling cutter mechanism and clamping the workpiece 10 4, and the rear clamping piece 6 arranged on the machine head 16 and located on the discharge side of the milli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com