Synchronous pressure welding device

A pressure welding, synchronous gear technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of dimensional deviation, unbalanced welding pressure on both sides of the spring, and the welding device cannot be accurately positioned. Improve the effect of dimensional deviation and welding pressure equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

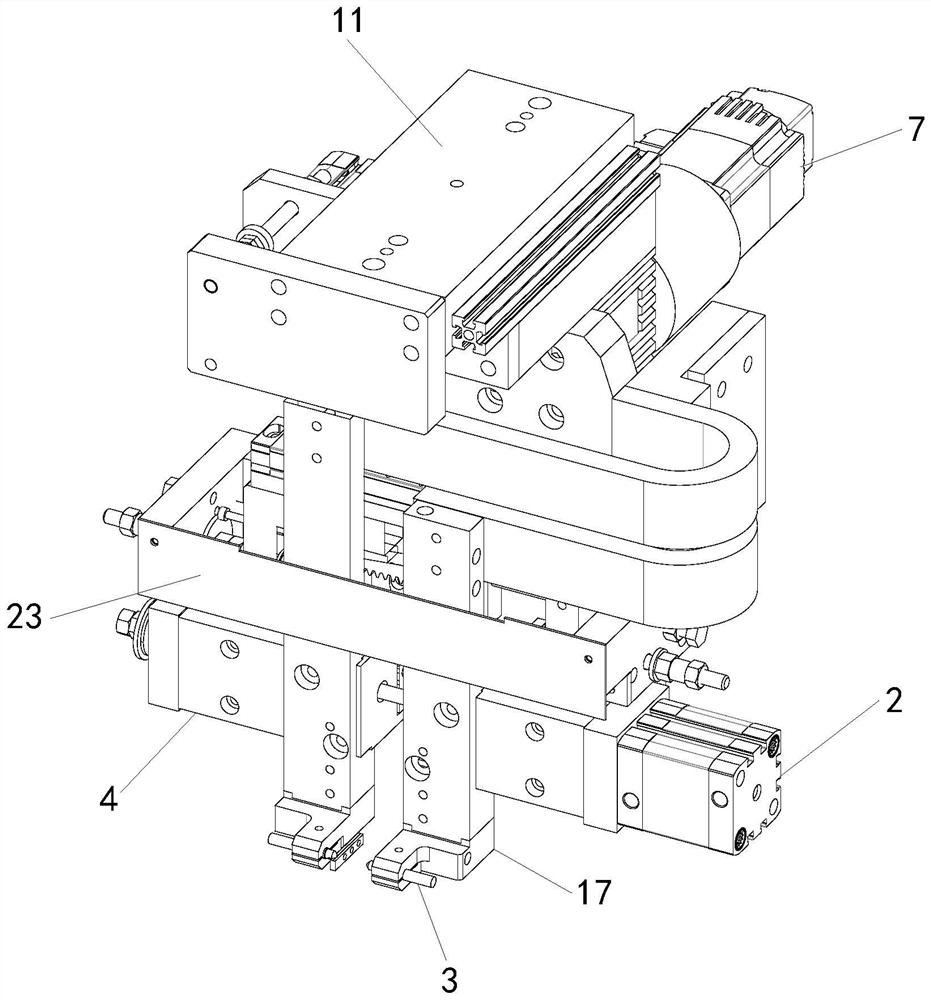

[0037] refer to Figure 1-Figure 6 , figure 1 It is a schematic diagram of the overall structure of the front end of a synchronous pressure welding device in an embodiment of the present invention;

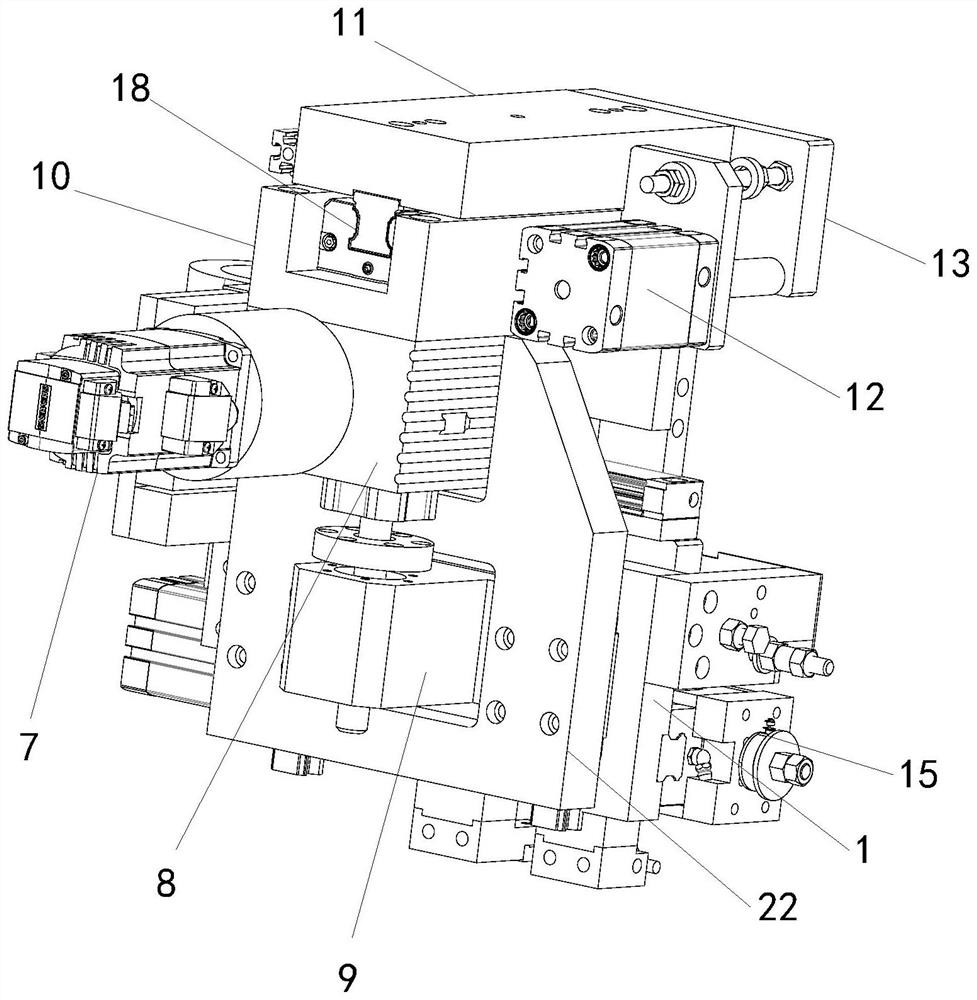

[0038] figure 2 It is a schematic diagram of the overall structure of the rear end of a synchronous pressure welding device in an embodiment of the present invention;

[0039] image 3 It is a side view of a synchronous pressure welding device in an embodiment of the present invention;

[0040] Figure 4 It is a schematic structural diagram of the welding mechanism in the embodiment of the present invention;

[0041] Figure 5 is the front view of the welding mechanism in the embodiment of the present invention;

[0042] Image 6 It is a schematic partial structure diagram of the welding mechanism in the front view in the embodiment of the present invention;

[0043] A synchronous pressure welding device specifically includes: a horizontal moving mechanism, a vertical movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com