Pneumatic spot welding tooling for passenger car axle housing and leaf spring backing plate

A technology for aerodynamic points of passenger car axle housings and plates, which is applied to auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems that the machining accuracy cannot meet the design requirements, occupy the production space of the workshop, and the machining error is too large, so as to facilitate production. Manage and create simple, powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

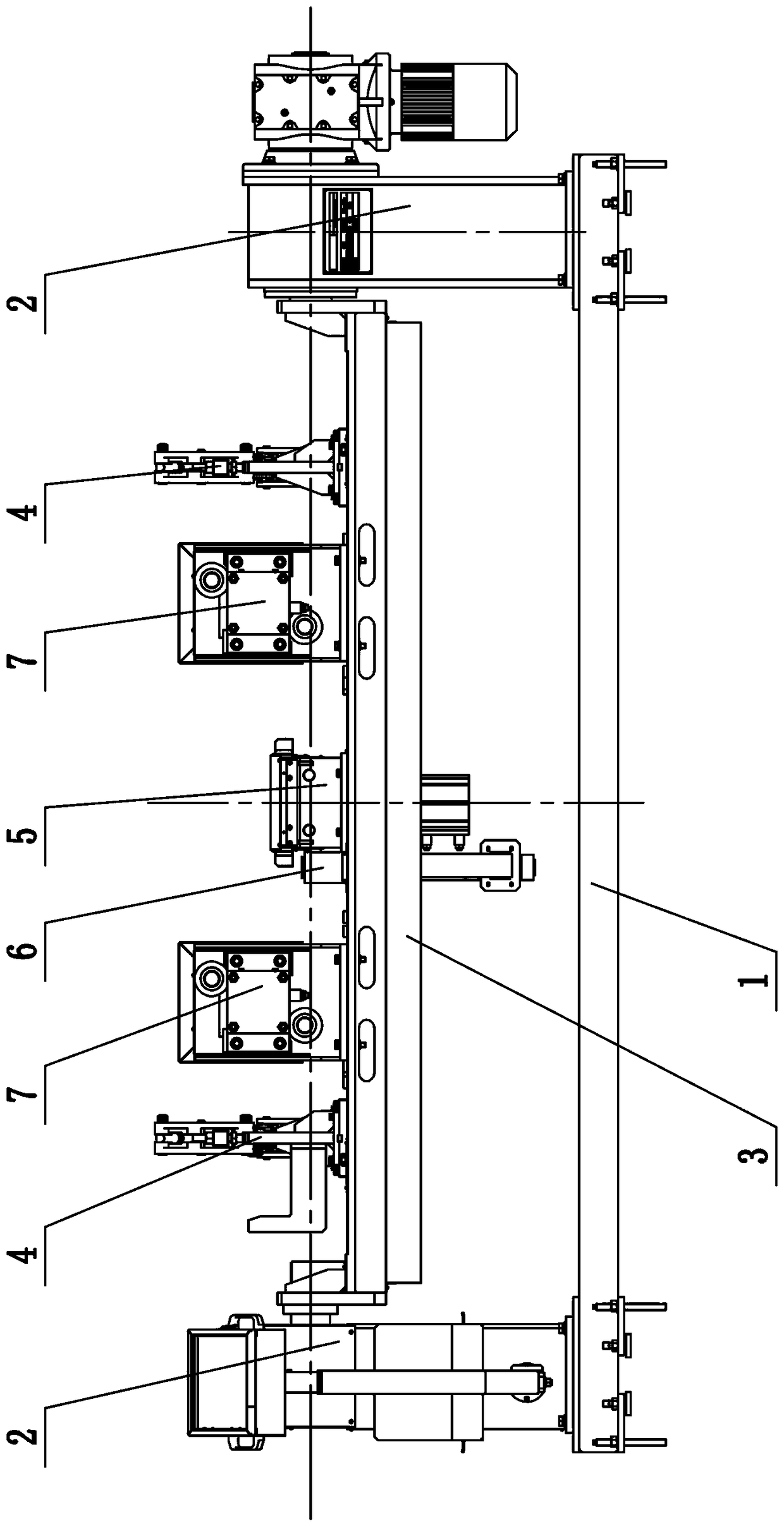

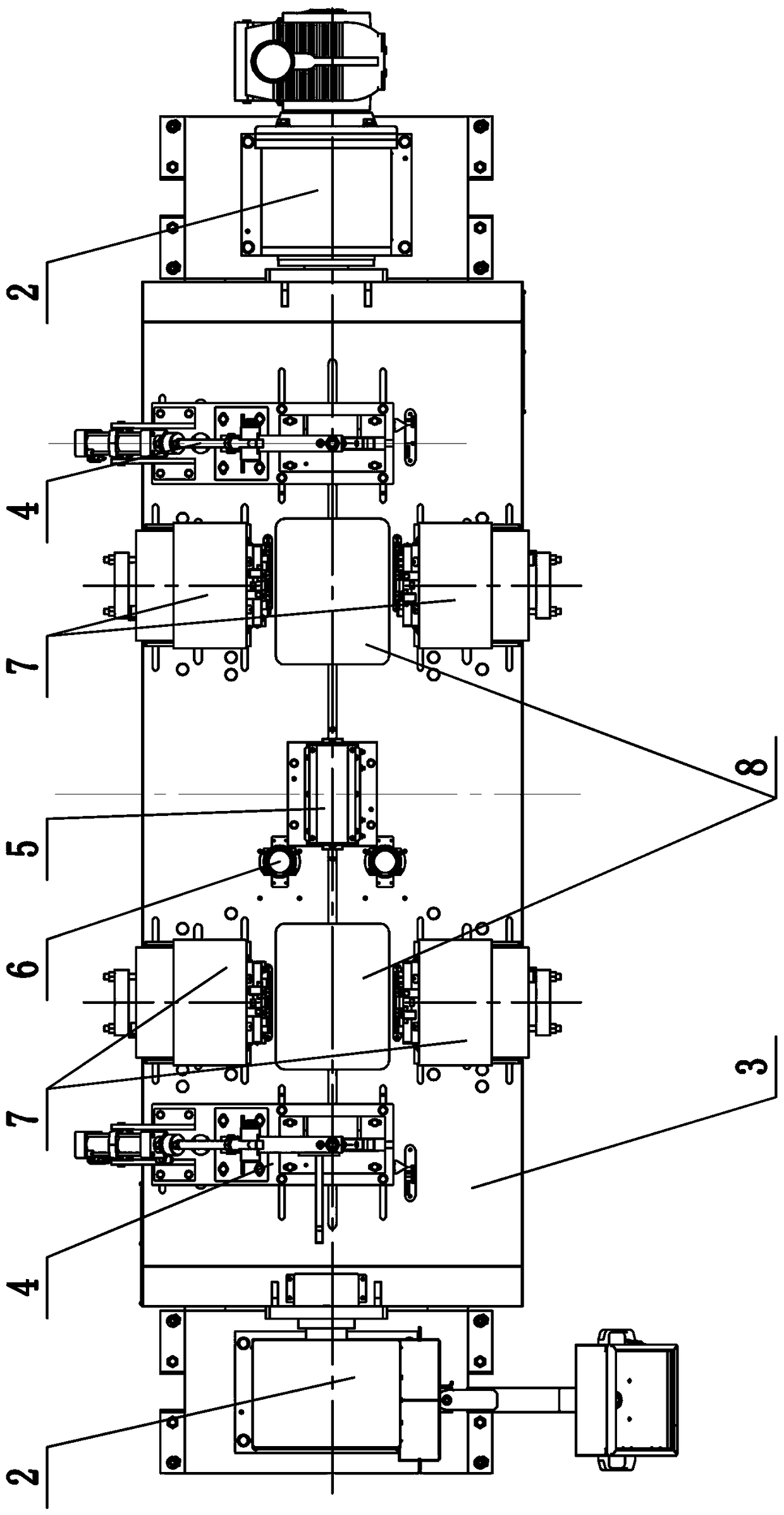

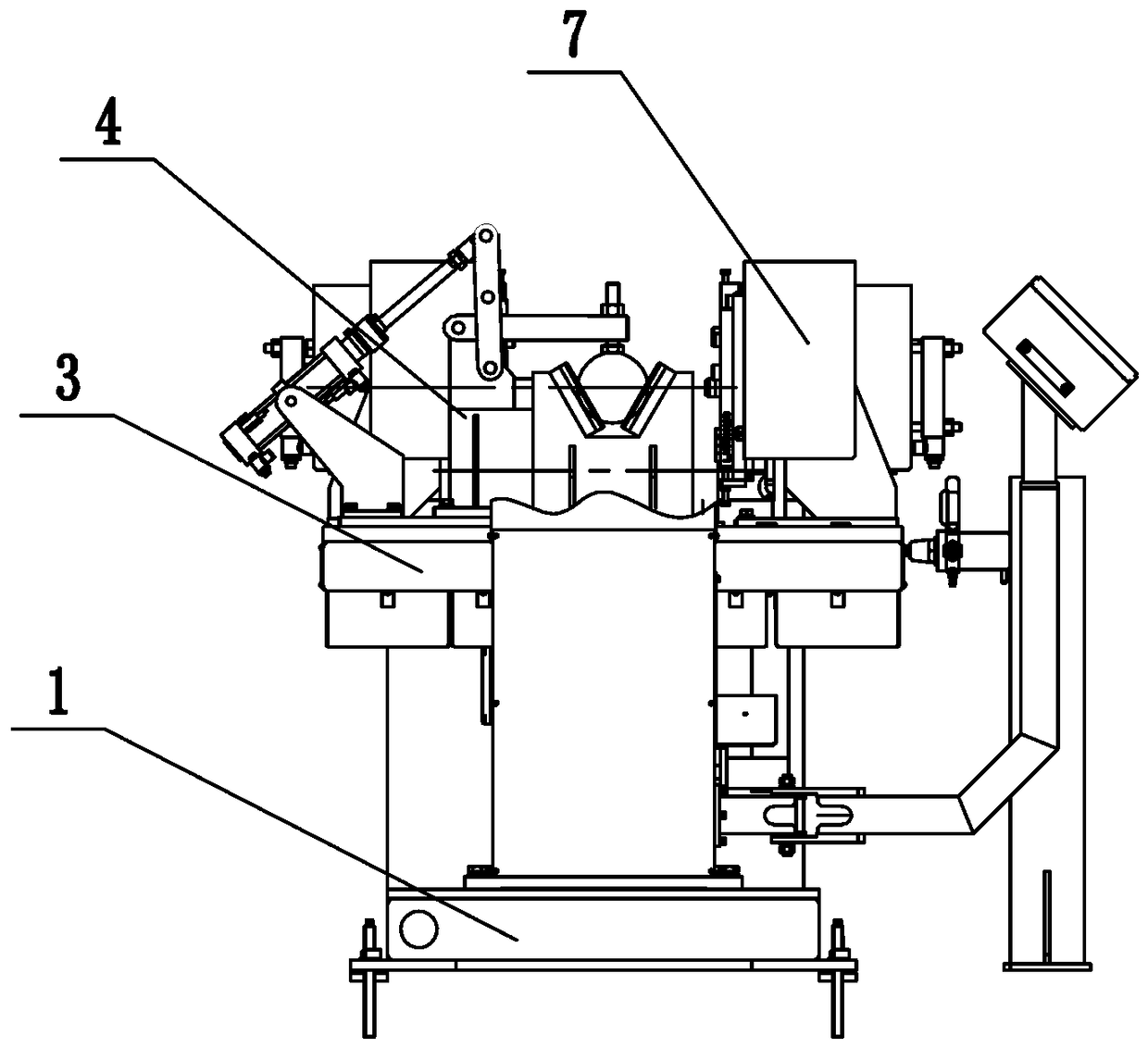

[0030] Such as Figure 1~Figure 11 As shown, a tool for pneumatic spot welding of a passenger car axle housing and a leaf spring backing plate, including a base 1, an overturning mechanism 2, an overturning platform 3, a supporting and pressing mechanism 4, a centering mechanism 5, a leveling mechanism 6 and a leaf spring pad Plate support mechanism 7, the base 1 is provided with an overturning mechanism 2, the overturning mechanism 2 drives the overturning platform 3 to overturn, and the overturning mechanism 2 includes an overturning support column 201, an overturning motor 202, a driving rotary shaft 203 and a driven rotary shaft 204, so An overturning support column 201 is respectively fixed on both sides of the base 1 described above, and the two overturning support columns 201 are movably connected to the active rotary shaft 203 and the driven rotary sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com