Intelligent mold manufacturing auxiliary system and method

An auxiliary system and mold manufacturing technology, applied in the direction of manufacturing tools, metal processing machinery parts, metal processing equipment, etc., can solve the problems of reduced coverage, difficult water flow blocking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

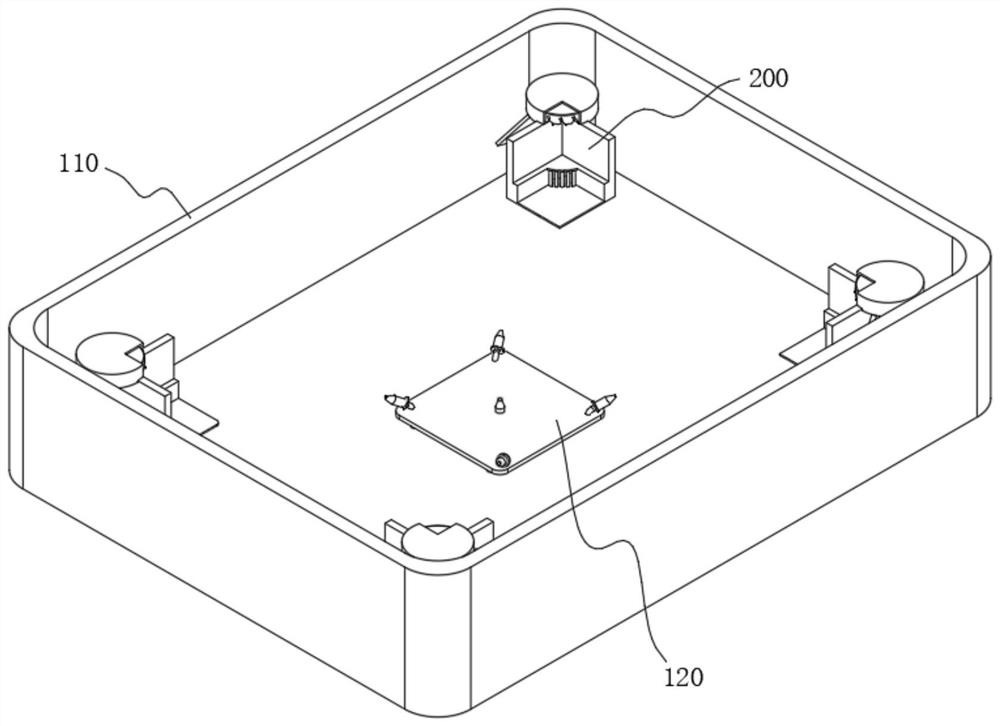

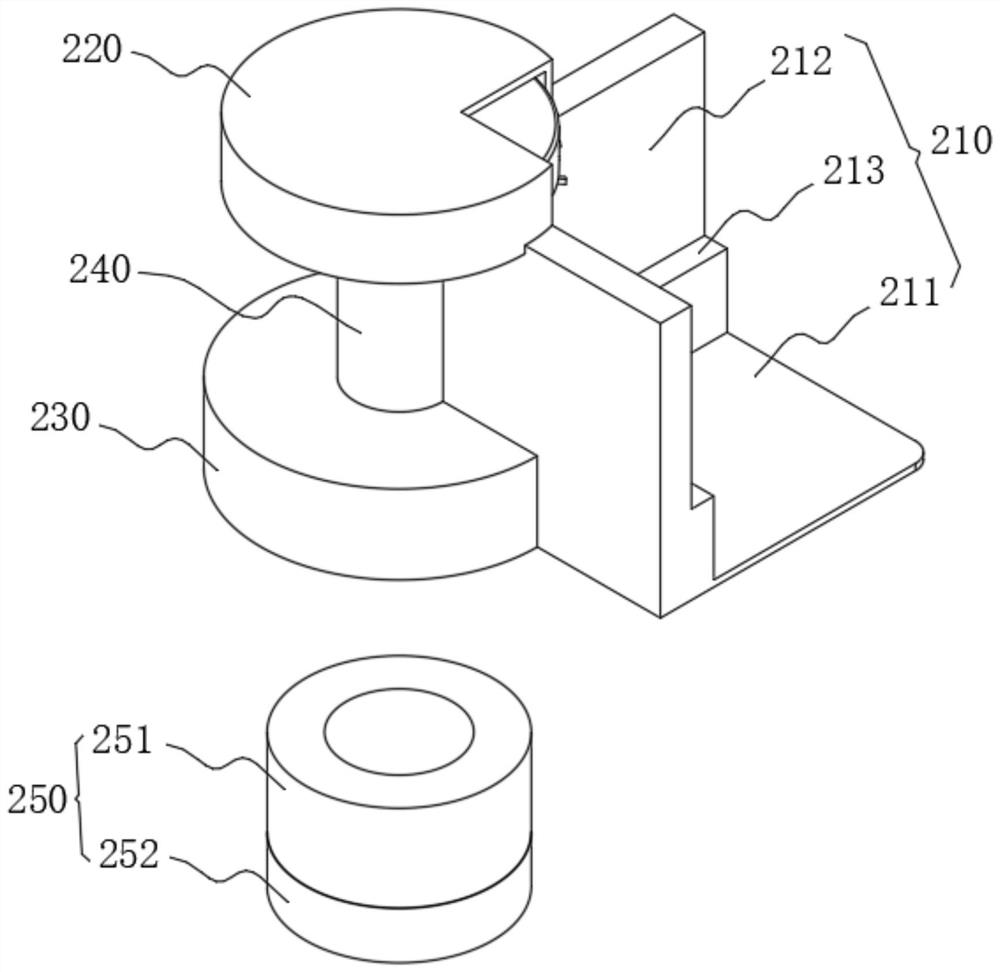

[0054] For the first embodiment, see image 3 As shown, the water flow guiding mechanism 200 includes a support member 210, a water outlet member 220 and a water inlet member 230. The support member 210 includes a side plate 212 in an "L" shape structure, and the side plate 212 is adapted to the casting plate 300 through the "L" shape structure. corner, and a flange 213 is provided on the side where the side plate 212 and the corner of the casting plate 300 are attached to support the casting plate 300. A plug space is formed, which is connected to the corner of the cast plate 300 through the plug space. The bottom of the flange 213 is provided with a bottom plate 211. After the cast plate 300 and the side plate 212 are installed, a water storage space is formed between the bottom plate 211 and the cast plate 300. In this way, the water flow ejected from the water flow output member 120 is blocked by the casting plate 300 and expands around, and then the expanded water flow en...

no. 3 example

[0063] The third embodiment, this embodiment specifically discloses a water flow output member 120. The water flow output member 120 includes a spray head 122. The spray head 122 is arranged at the bottom of the operating cavity 100A. The bottom of the spray head 122 is provided with a water inlet pipe 1221. The water inlet pipe 1221 passes through the water tank. The bottom wall of 110 is connected with the nozzle 122 , and the water flow connected to the water inlet pipe 1221 is sprayed out through the nozzle 122 .

no. 4 example

[0064] The fourth embodiment, this embodiment discloses another implementation of the water flow output member 120 , please refer to Figure 8 As shown, there are at least five spray heads 122, preferably five, and the water flow output member 120 further includes a square connecting plate 121, and the bottom of the connecting plate 121 is provided with a plurality of pillars 1211, through which the connecting plate 121 is installed on the On the bottom wall of the water tank 110, four of the five spray heads 122 are arranged at the corners of the connection plate 121 and face the water storage cavity 211A, and the remaining one is arranged at the center of the connection plate 121, towards the top, when working , see Figure 9 and Figure 10 As shown in the figure, the water flow from the nozzles 122 at the center is blocked by the casting plate 300 and spreads around, but the water flow into the water storage cavity 211A is limited, so the nozzles 122 at the four corners ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com