Multi-color automatic material changing 3D printer

A 3D printer, automatic technology, applied in the direction of 3D object support structure, processing material handling, manufacturing tools, etc., can solve the problems of affecting printing efficiency, slow printing speed, color pollution, etc., to achieve high flexibility, high possibility of combination, Excellent print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

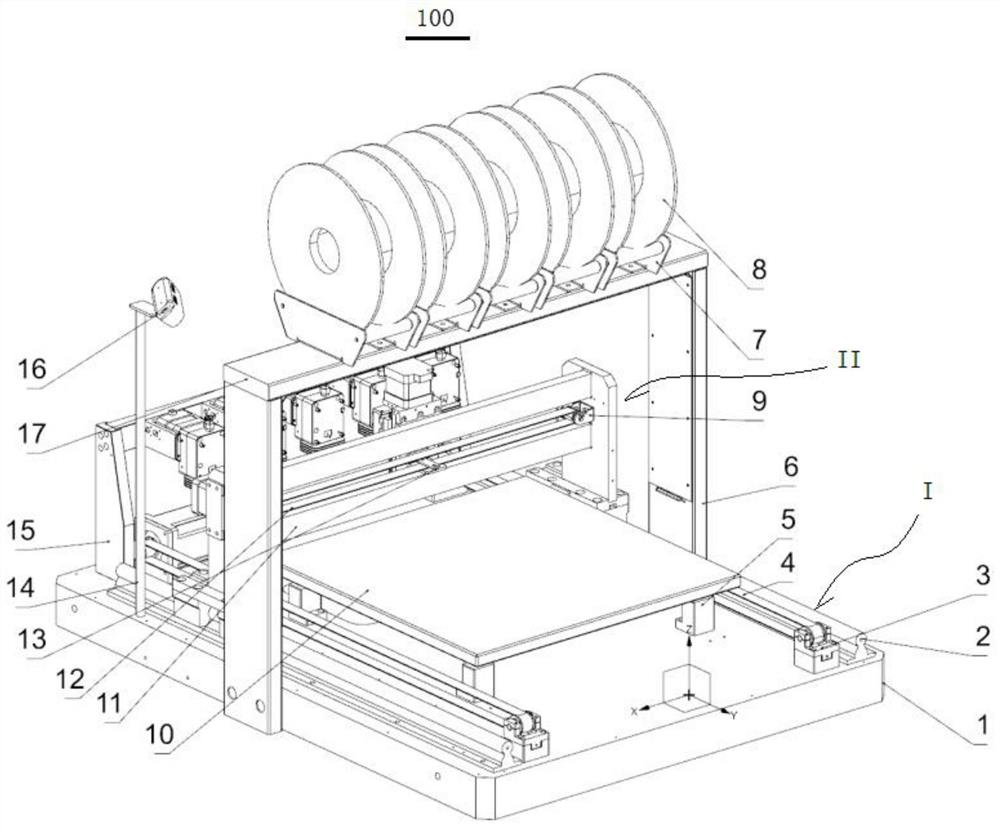

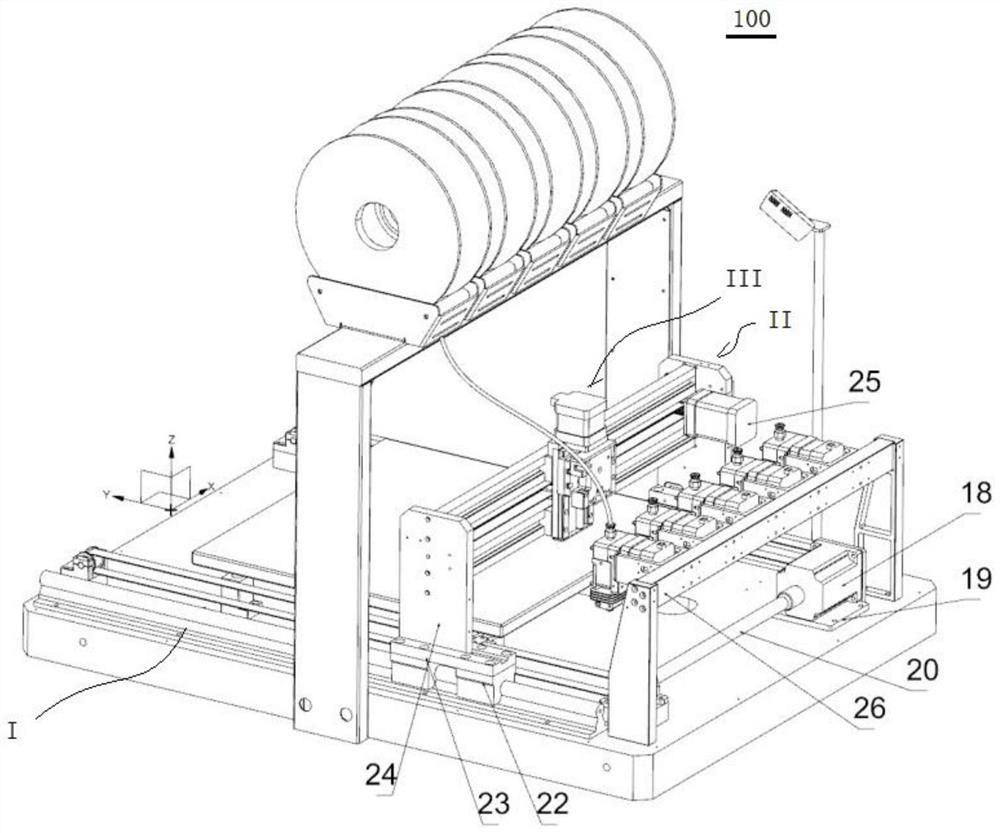

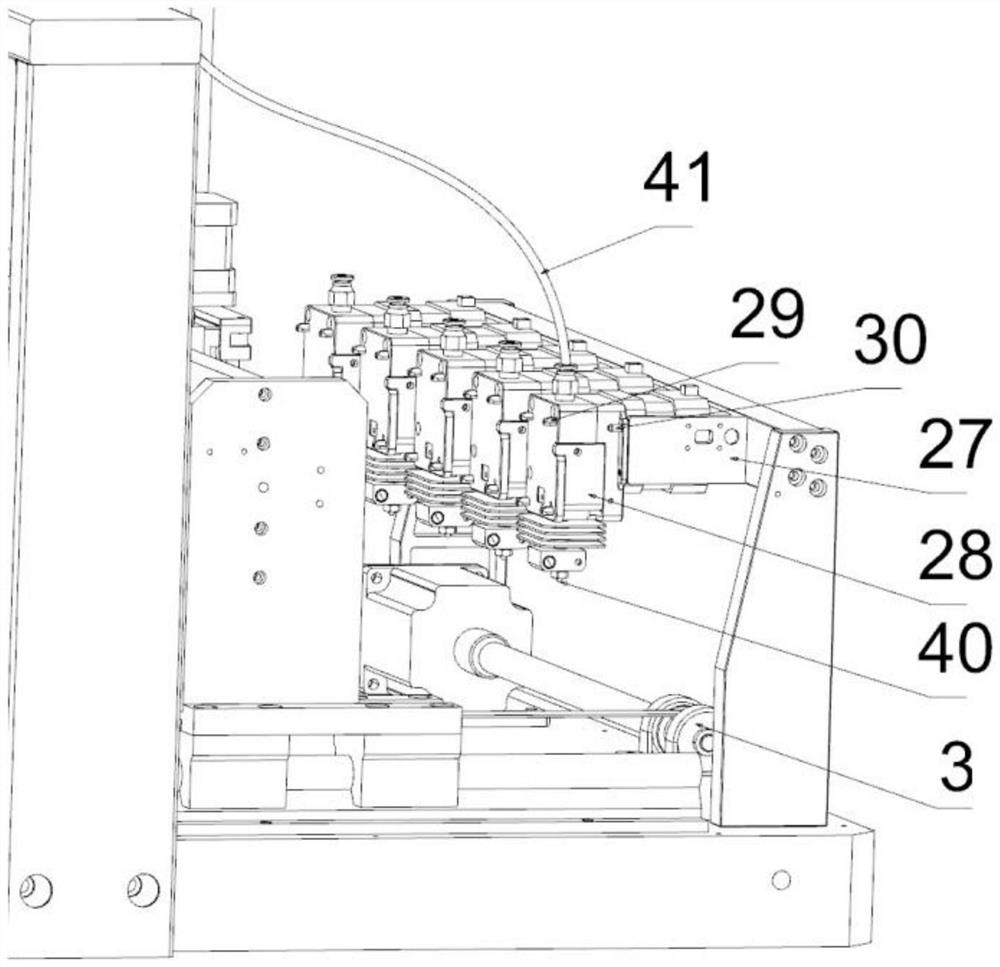

[0058] figure 1 It is a schematic perspective view of a multi-color automatic material changing 3D printer according to an embodiment of the present application from an angle. figure 2 figure 1 It is a schematic three-dimensional view of a multi-color automatic material changing 3D printer from another angle according to an embodiment of the present application. image 3 Yes figure 2 A schematic enlarged view of a plurality of printheads and the printhead fixing assembly in . Figure 4 Yes figure 2 Schematic enlarged partial view of the Z-axis motion assembly in , mounted with the X-axis slider and X-axis belt clamping block.

[0059] like figure 1 shown, see also figure 2 , this embodiment provides a multi-color automatic refueling 3D printer 100, including: a base plate 1, a printing platform 10, a plurality of material trays 8, a plurality of printings, a Y-axis motion component I, an X-axis motion component II and a Z-axis Motion component III (see figure 2 )....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com