High-cohesive-force carbon fiber composite bar for cement concrete member and preparation method

A cement concrete, high-adhesion technology, used in building components, structural elements, building reinforcements, etc., can solve the problems of lack of failure protection, poor adhesion between fiber composite bars and concrete, and improve the adhesion. , the effect of improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

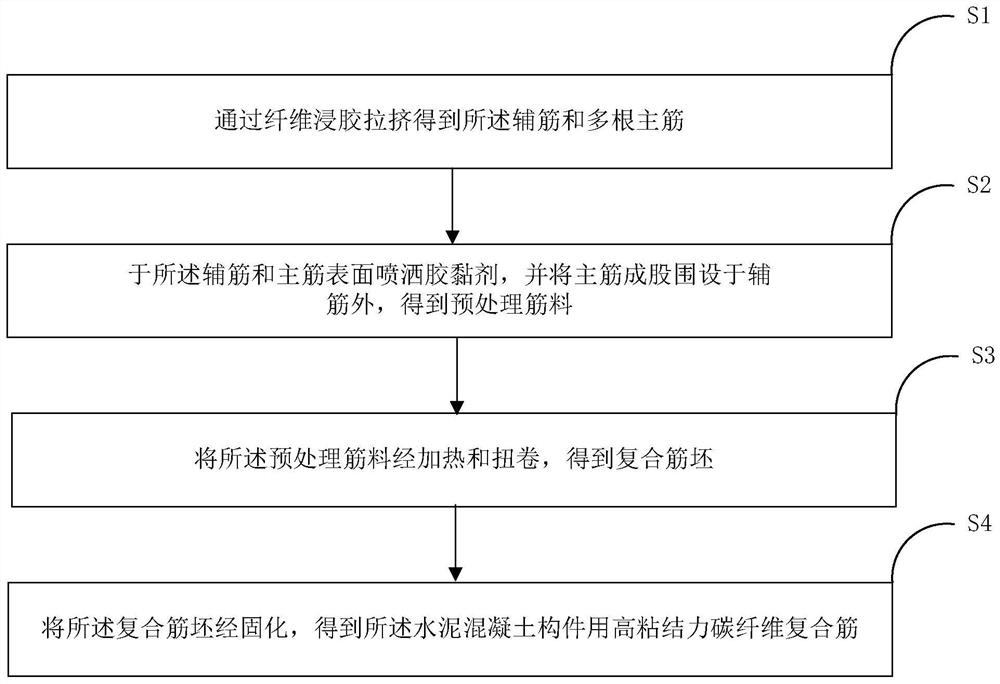

[0044] As an optional embodiment, it also includes the following steps:

[0045] S2.1. After spraying the adhesive, sandblast the surfaces of the auxiliary rib 10 and the main rib 20 .

[0046] Through the sandblasting operation in step S2.1, the roughness of the surface of the composite rib is further improved, and the bonding force between the composite rib and the concrete is further improved.

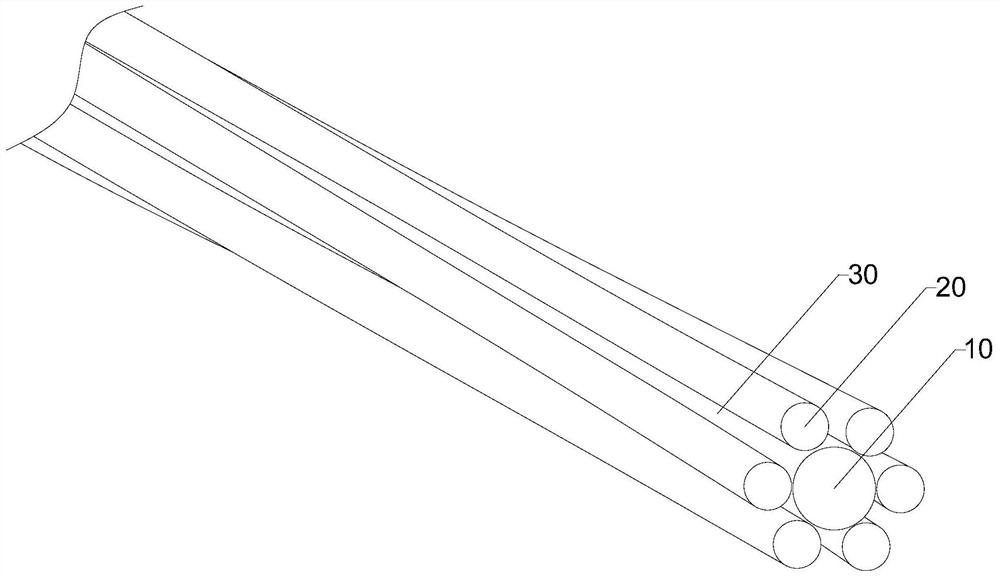

[0047] As an optional embodiment, the preparation raw materials of the auxiliary rib 10 and the main rib 20 include a resin matrix and impregnated fibers. The resin matrix can effectively improve the corrosion resistance of the composite bars, and the impregnated fibers can further improve the mechanical strength of the resin matrix.

[0048] As an optional embodiment, the impregnated fibers include any one or a combination of carbon fibers, glass fibers, aramid fibers and basalt fibers. The use of the above fibers can effectively improve the modulus and strength of the composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com