Integrated forepoling for reversed loader head

A technology of advanced support and reloading machine, which is applied in the direction of mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problem of inability to meet the requirements of intelligent working face construction, increase the width of the roadway, and cannot arrange two sets of advanced Support and other problems, to achieve the effect of light weight, small occupation of roadway space, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

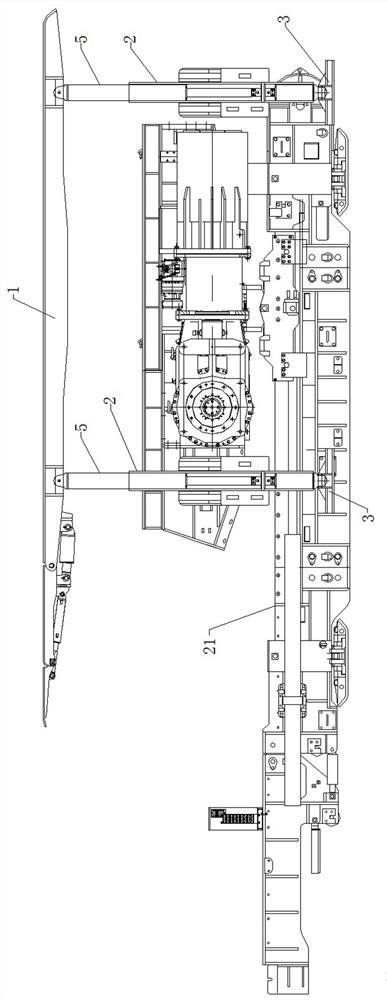

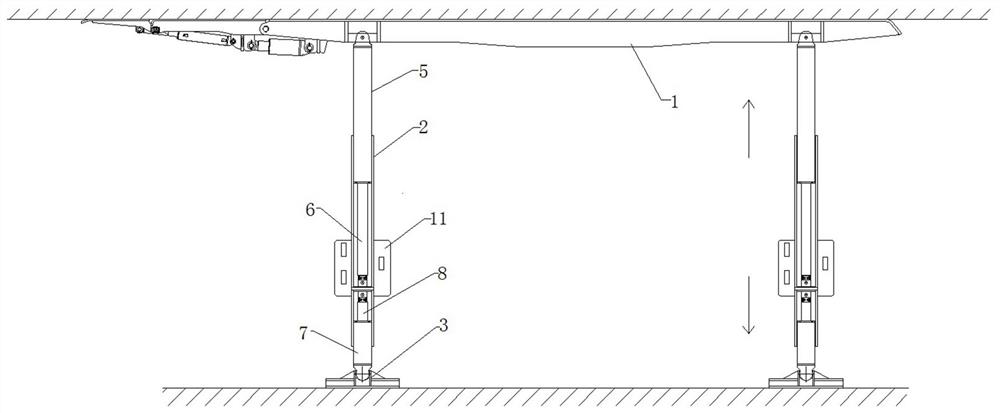

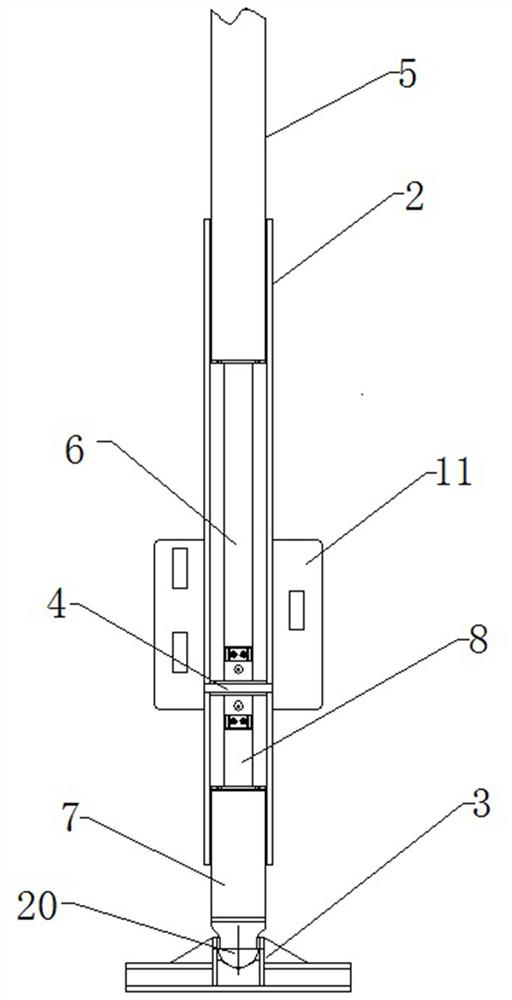

[0029] Embodiment 1: An integrated advance bracket for the head of a loader, see Figure 1-Figure 8 , including the top beam 1, under the top beam 1, there are vertical guide cylinders 2 at the front and rear sides of the motor of the loader 21, respectively, a column shoe 3 is provided under the guide cylinder 2, and a middle part of the guide cylinder 2 is provided with The horizontal fixed plate 4 is provided with an upper column at a position above the fixed plate 4 in the guide cylinder 2. The upper column includes an upper hydraulic cylinder barrel 5 and an upper movable column 6 located in the upper hydraulic cylinder barrel 5. The upper hydraulic cylinder barrel 5 Its upper end is hinged with the top beam 1, and the lower end of the upper movable column 6 is fixedly connected with the top surface of the fixed plate 4; the upper hydraulic cylinder 4 moves in the guide cylinder 2 to drive the top beam 1 to move up and down.

[0030] A lower column is provided in the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com