Pump body powerful self-suction structure

A powerful, self-priming technology, applied in the direction of pumps, pump components, driving pumps, etc., can solve the problems of only 2.5-3.5 meters, occupying a large space on site, and long self-priming time, achieving high self-priming height, saving space, The effect of short self-priming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to specific embodiments and accompanying drawings to help understand the content of the present invention.

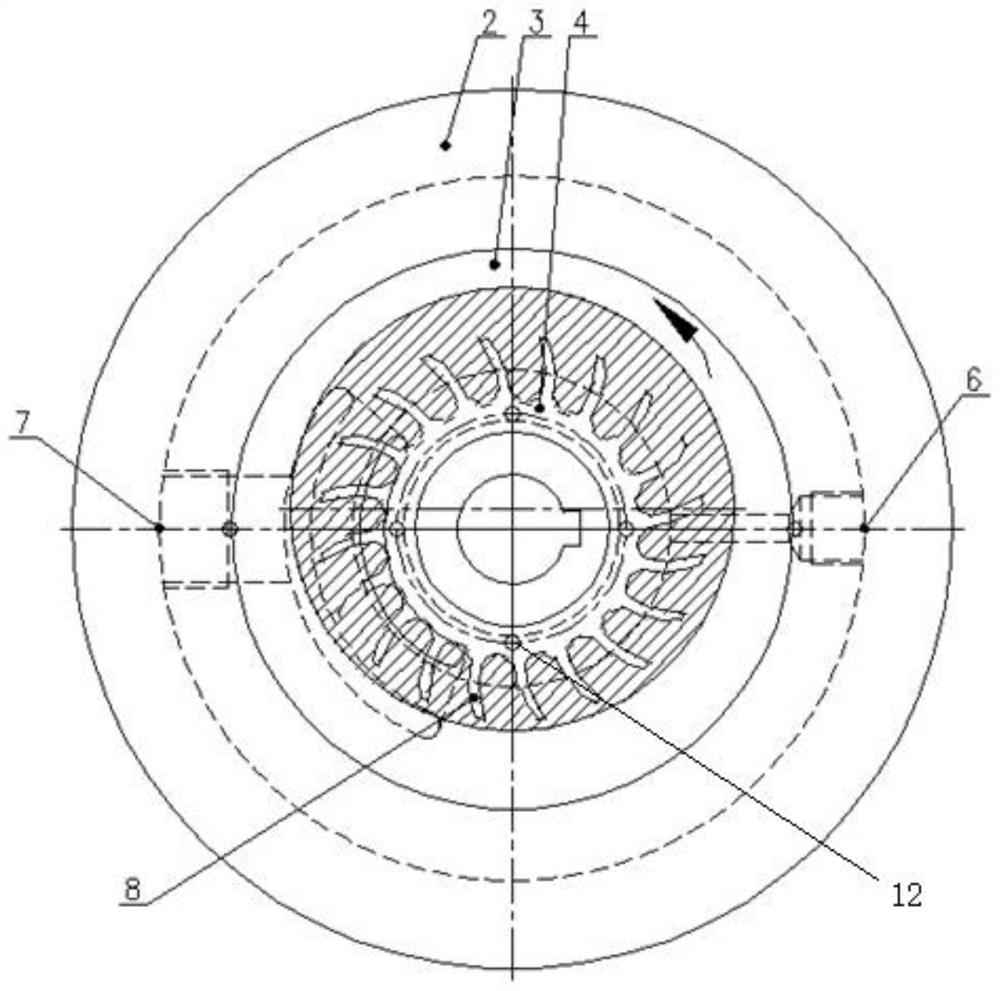

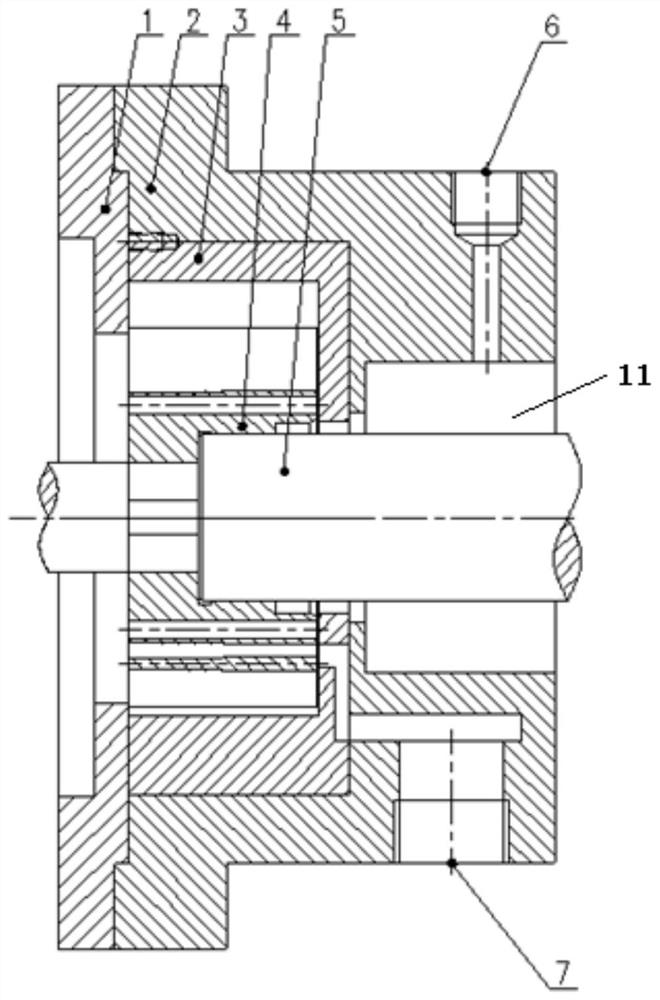

[0019] like Figure 1-2 shown, respectively, are a front view and a side cross-sectional view of a strong self-priming structure of a pump body provided by the present invention. The strong self-priming structure of the pump body includes a pump cover 1, an eccentric chamber seat 2, an eccentric chamber 3, an impeller 4 and a pump shaft 5. The impeller 4 is installed between the pump cover 1 and the eccentric chamber 3, and its front and rear clearance is 0.3- 0.35mm, the inner hole of the impeller 4 and the pump shaft 5 are clearance fit. Preferably, the inner hole of the impeller 4 is installed on the pump shaft 5 according to the H7 / h6 small clearance fit.

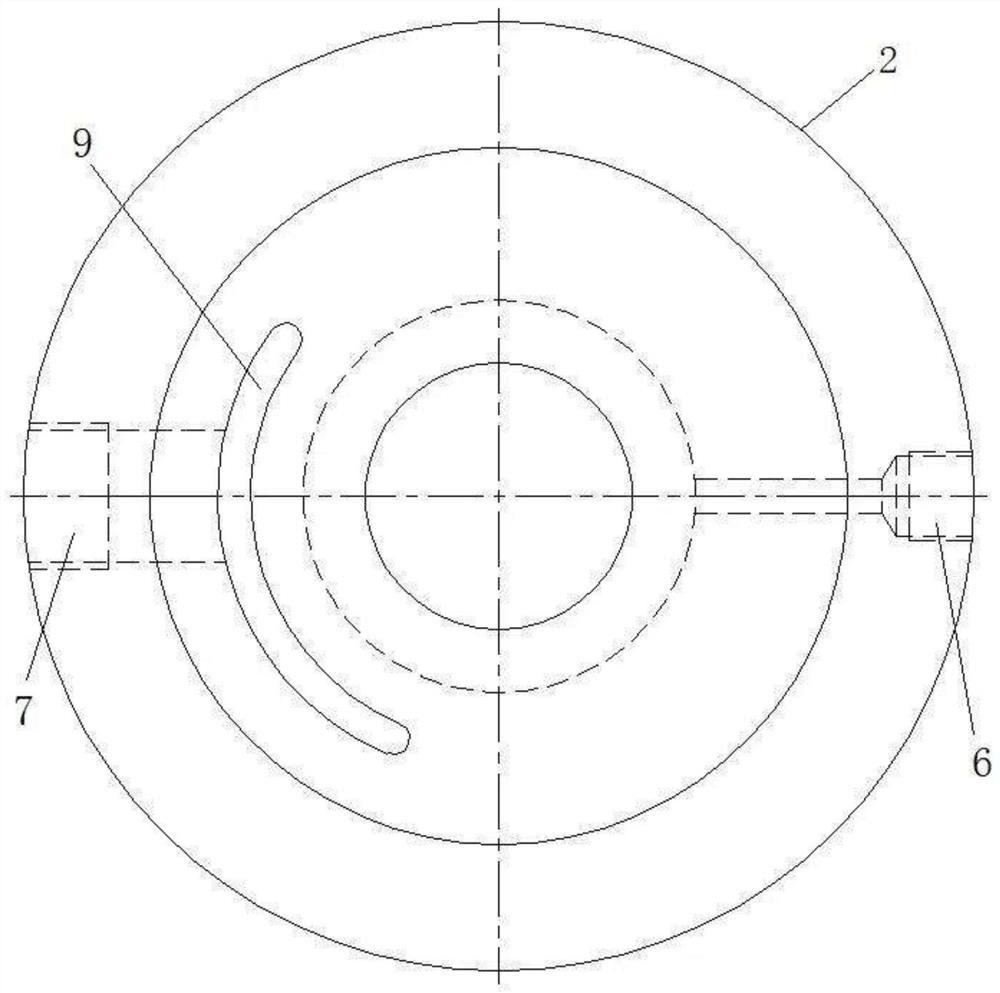

[0020] like Figure 4 As shown, it is a front view of the eccentric chamber of a strong self-priming structure of a pump body provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com