Processing method of flue gas duct measuring section and flue gas duct measuring section

A processing method and flue gas duct technology, which is applied in the field of flue gas duct flow detection, can solve the problems of large fluctuations in the detection data of flow detection points, low measurement accuracy, and large gas disturbance range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

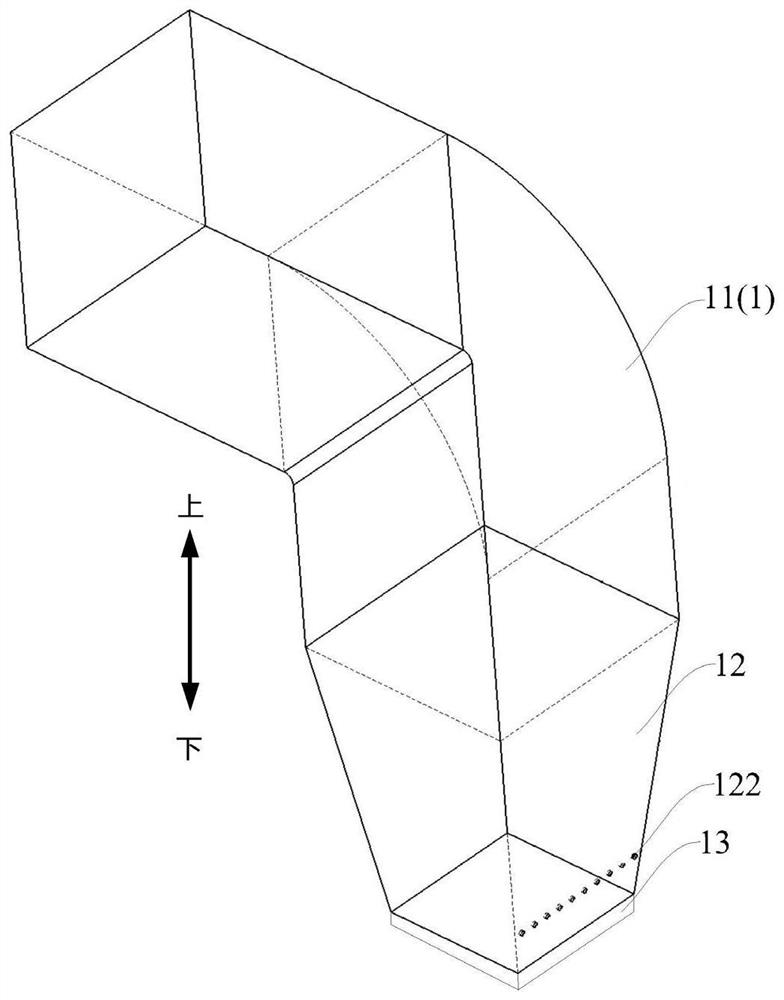

[0028] like figure 1 As shown, the flue gas duct measurement section 1 of the embodiment of the present invention includes a curved duct 11 , a detection duct 12 and a straight duct 13 that are connected in sequence.

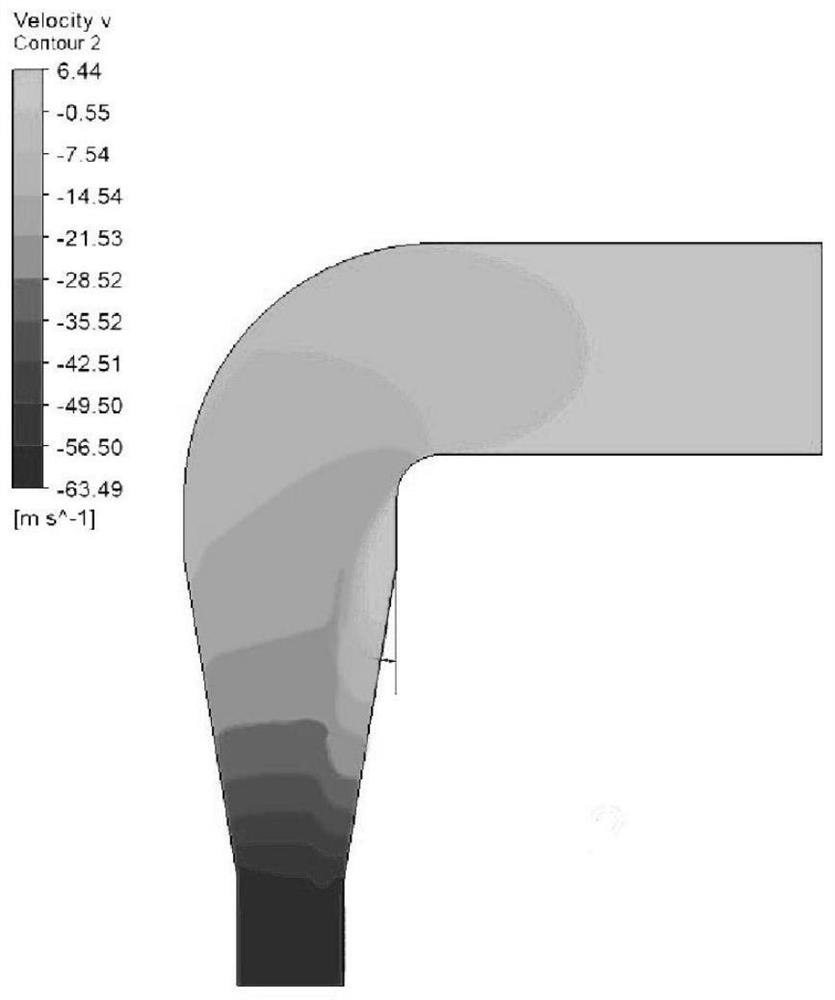

[0029] The angle between the inner wall surface of the detection pipe 12 and the center line of the detection pipe 12 is greater than 0 degrees and less than or equal to 15 degrees.

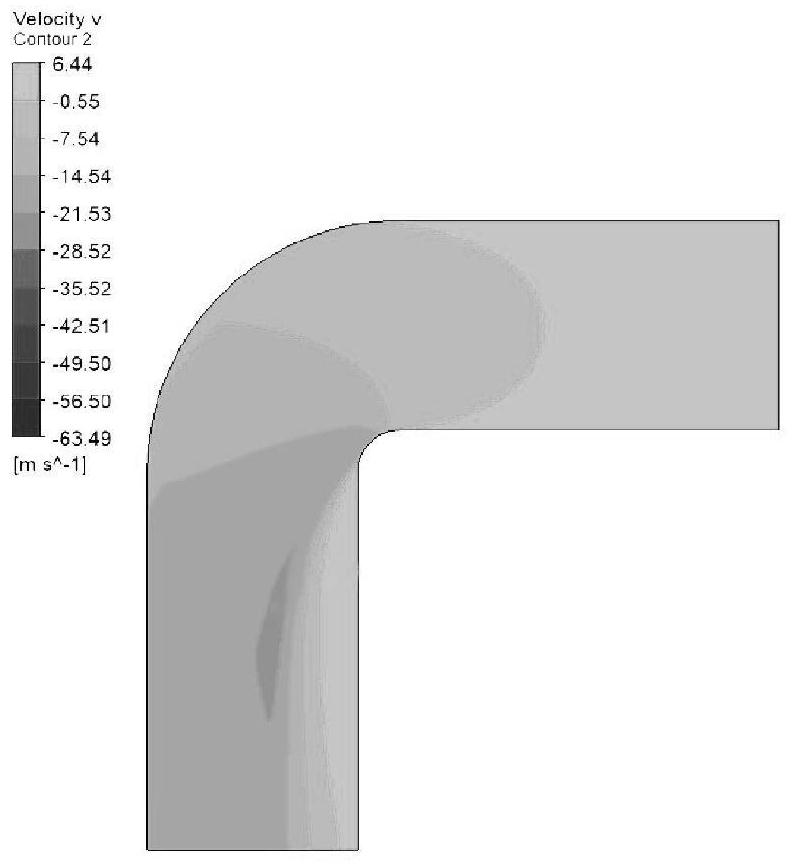

[0030] The inventors found that: figure 2 As shown in the related art, when the gas flows in the pipeline, the gas obviously has a large gas disturbance at the downstream of the bend, that is, the gas flow velocity on the same cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com