Extra-high voltage cable stress cone jacking device

A technology of jacking device and stress cone, applied in cable installation device, cable installation, electrical components, etc., can solve the problems of reduced stress cone effect, cable joint failure, easy to absorb dust, etc., to increase friction and facilitate cleaning. Dust, fixed and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

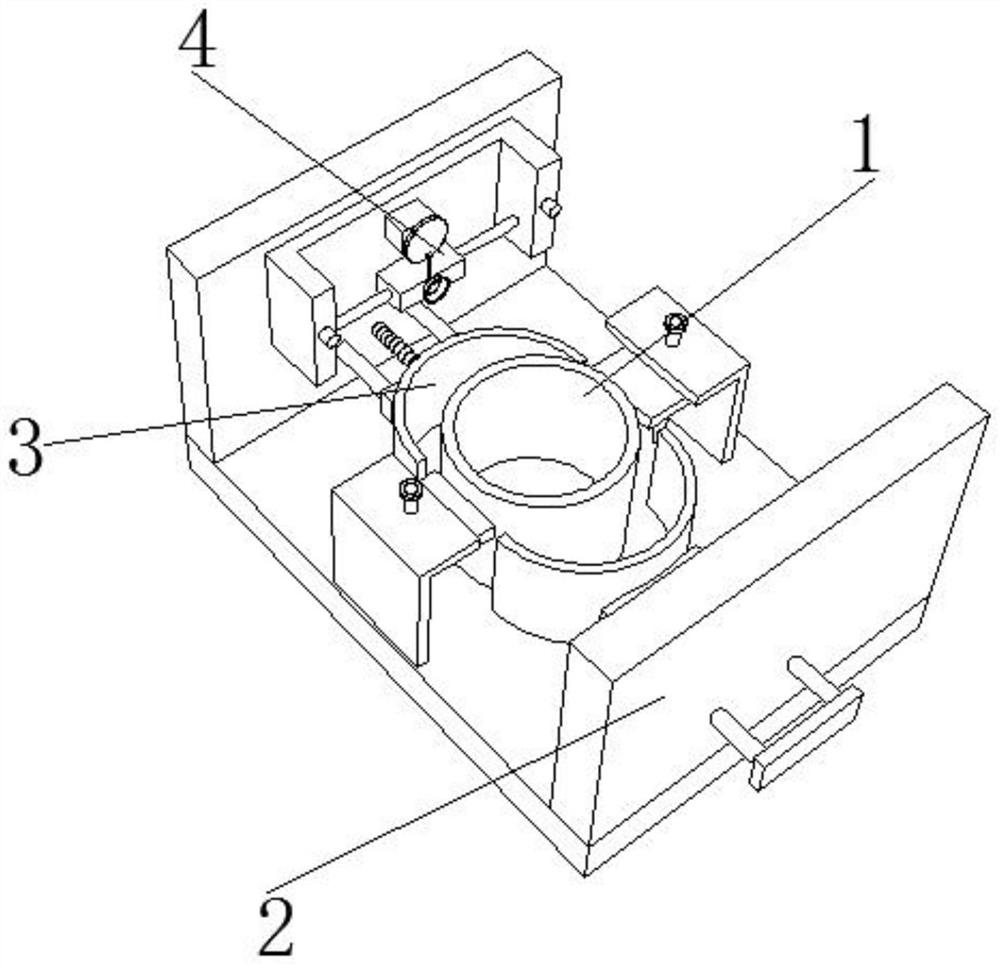

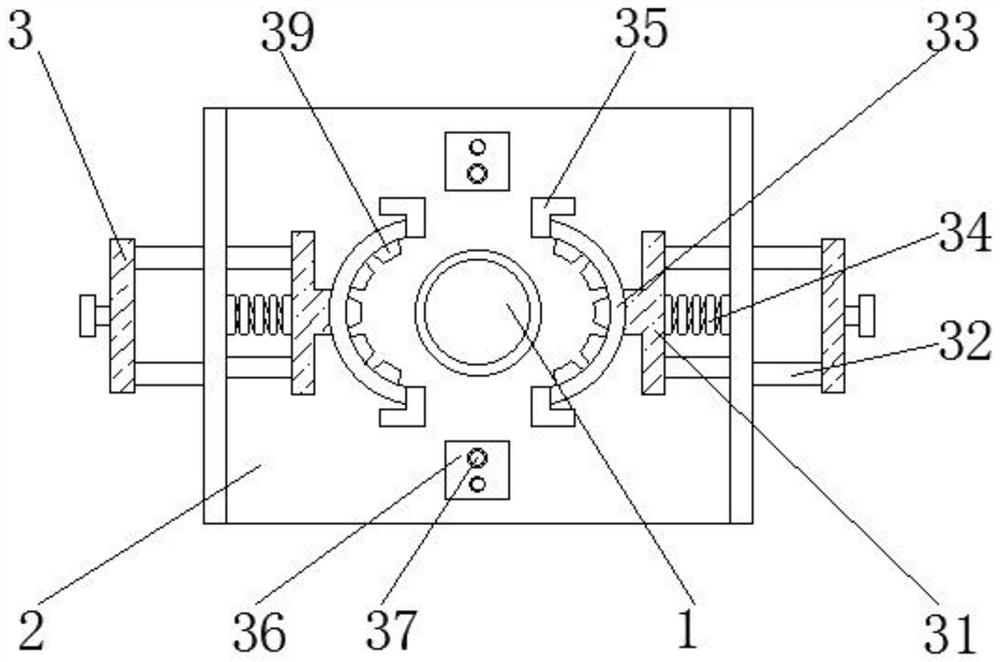

[0030] like Figure 1-6 As shown in the figure, the present invention provides an ultra-high voltage cable stress cone pressing device, comprising a stress cone body 1, a base 2 is arranged below the stress cone body 1, and a clamping mechanism 3 is arranged above the base 2 of the stress cone body 1 , one side of the clamping mechanism 3 is provided with a dust suction mechanism 4, the clamping mechanism 3 includes a connecting block 31, a sliding rod 32 and a clamping bar 33, the connecting block 31 is arranged on both sides of the stress cone body 1, and the sliding rod 32 is fixed Installed on the outer wall of one side of the connection block 31, the outer wall of the sliding rod 32 is movably connected with the inner wall of the base 2, the clamping bar 33 is fixedly installed on the outer wall of the connection block 31, and the dust suction mechanism 4 includes a motor 41 and a moving block 42. And the vacuum cleaner 43, the motor 41 is arranged above the base 2, the m...

Embodiment 2

[0033] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the rebound assembly 39 includes an arc-shaped block 391, an elastic hemisphere 392 and a fan-shaped connecting block 393, and the arc-shaped block 391 is fixedly installed in the clip On the inner wall of the tightening bar 33, the elastic hemisphere 392 is fixedly installed on one side outer wall of the arc block 391, the fan-shaped connecting block 393 is fixedly installed on one side outer wall of the elastic hemisphere 392, and the one side outer wall of the arc block 391 is fixedly installed There is an elastic connecting column 394, one end of the elastic connecting column 394 is fixedly connected with one side outer wall of the fan-shaped connecting block 393, a fan-shaped rubber frame 395 is fixedly installed on one side outer wall of the fan-shaped connecting block 393, and the inner wall of the fan-shaped rubber frame 395 is fixedly installed...

Embodiment 3

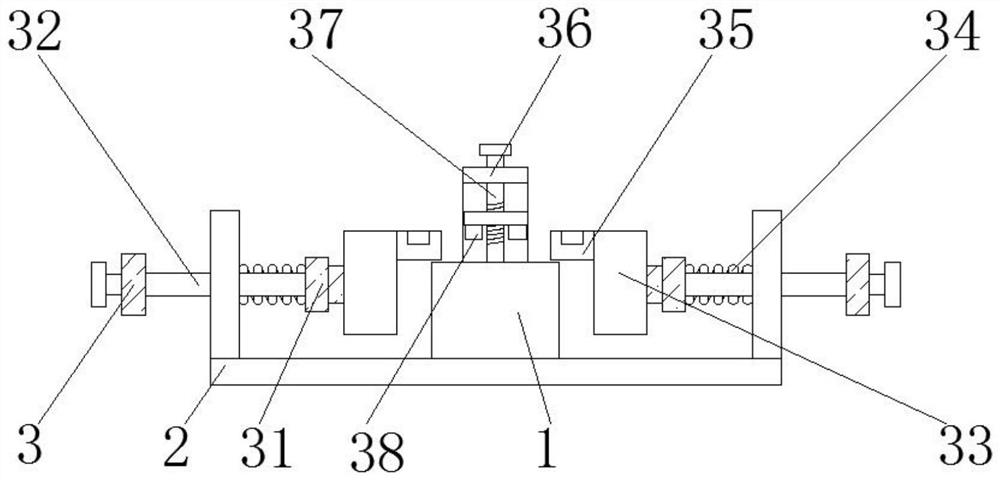

[0036] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a support rod is fixedly installed on one side outer wall of the base 2, and a door-shaped block is movably installed on the outer wall of the support rod. One side inner wall of the motor 41 is fixedly connected with the one side outer wall of the motor 41, a turntable 44 is fixedly installed on the output shaft of the motor 41, a hinge rod is movably installed on one side outer wall of the turntable 44, and the bottom end of the hinge rod is connected to the top of the moving block 42. Fixed connection, the inner wall of the door-shaped block is fixedly installed with a round rod 45, the outer wall of the round rod is movably connected with the inner wall of the moving block 42, a support block is fixedly installed on the outer wall of one side of the base 2, and the inner wall of the support block is movably installed with a clamping rod 46. One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com