Environment-friendly water mist spraying flue gas efficient purification device

A technology for purifying device and flue gas, which is applied in combination device, climate change adaptation, mixer with rotary stirring device, etc., can solve the problems of multiple purification of flue gas, lowering air quality, and inability to remove all harmful substances, etc. To achieve the effect of reducing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

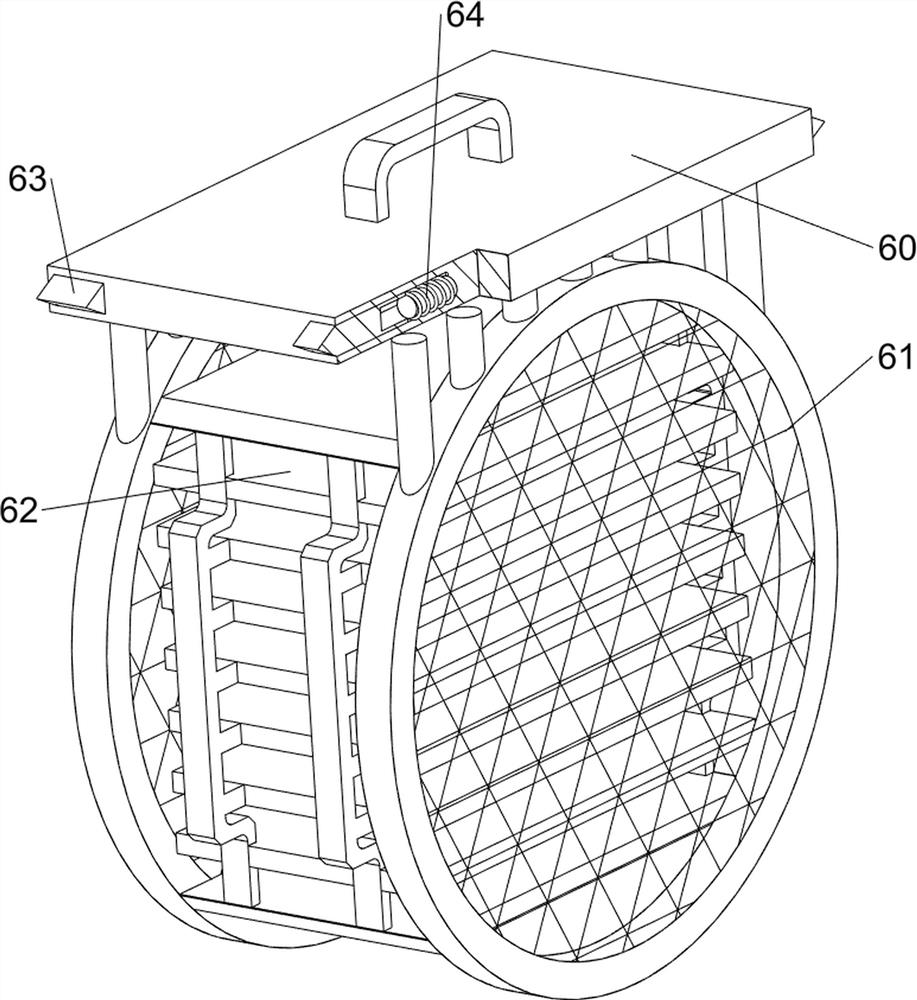

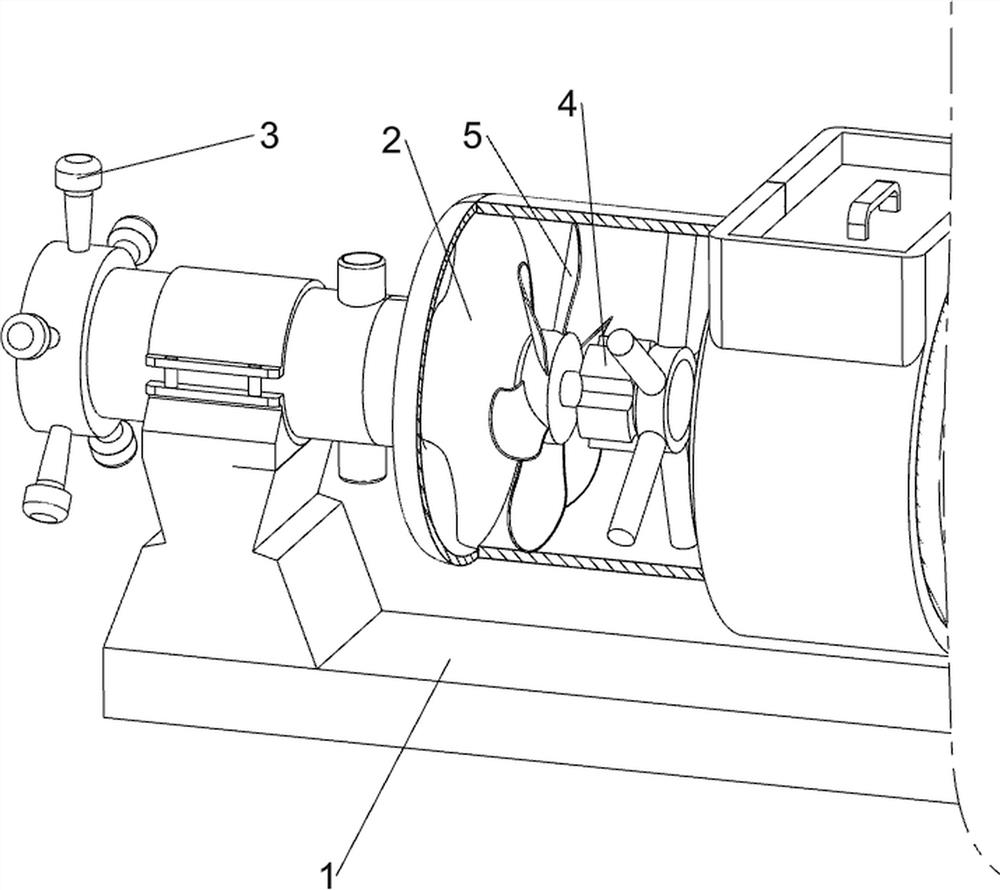

[0089] An environmentally friendly water mist spraying flue gas efficient purification device, such as Figure 1-Figure 12 As shown, it includes a bottom frame 1, an air intake pipe 2, a connecting pipe 3, a motor 4, a fan blade 5, a filter mechanism 6, a feeding mechanism 7, a spray mechanism 8 and an air intake mechanism 9. The left side of the top front side of the bottom frame 1 There is an intake pipe 2, the inner side of the intake pipe 2 is opened with a port, and a check valve is installed on the left side of the intake pipe 2, a connecting pipe 3 is installed on the left side of the intake pipe 2 by means of threads, and the left side of the intake pipe 2 is installed on the left side. A motor 4 is installed, a fan blade 5 is connected to the output shaft of the motor 4, a filter mechanism 6 is installed in the middle of the intake pipe 2, the filter mechanism 6 is located on the right side of the motor 4, and a feeding mechanism 7 is provided on the right side of the ...

Embodiment 2

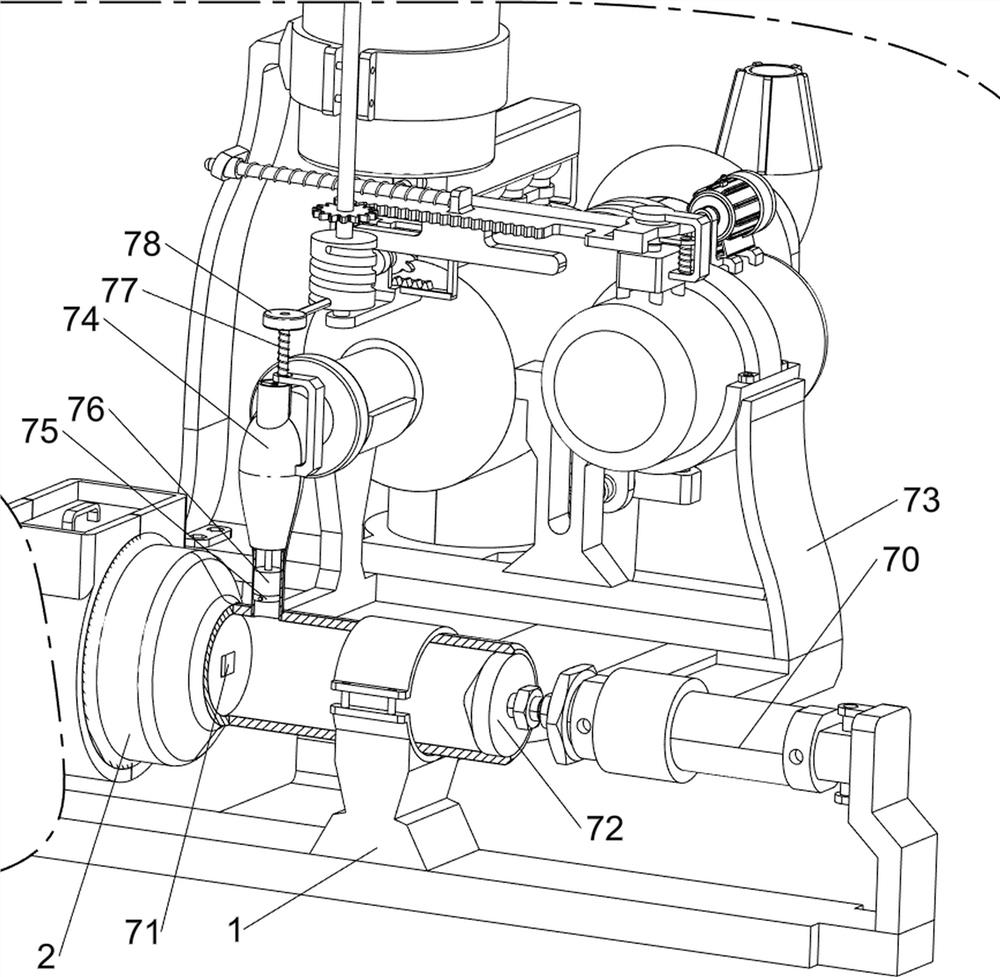

[0100] On the basis of Example 1, as figure 1 , Figure 13 , Figure 14 , Figure 15 and Figure 16 As shown, it also includes a rocking mechanism 10. The rocking mechanism 10 includes a friction rod 100, a third rotating shaft 101, a friction wheel 102, a missing gear 103 and a rack frame 104. The bottom of the rack rod 92 is provided with a friction rod 100 to guide the A third rotating shaft 101 is rotatably connected to the front side of the top of the air pipe 74 , a friction wheel 102 is connected to the front side of the third rotating shaft 101 , the friction wheel 102 is rotatably matched with the friction rod 100 , and the rear side of the third rotating shaft 101 is connected to a missing gear 103 , the front side of the top of the air duct 74 is slidably provided with a rack 104 , the rack 104 is engaged with the missing gear 103 , and the rack 104 is connected with the nozzle 811 .

[0101] When the liquid needs to be uniformly unloaded so that the flue gas ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com