Pouring method tooth punching heat insulation aluminum profile and forming method

A molding method and technology for aluminum profiles, which are applied in the fields of climate sustainability, metal extrusion die, climate change adaptation, etc., can solve the problems of inconvenient polyurethane rubber strip locking, inconvenient polyurethane curing, etc., and save processing time. , the effect of saving waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

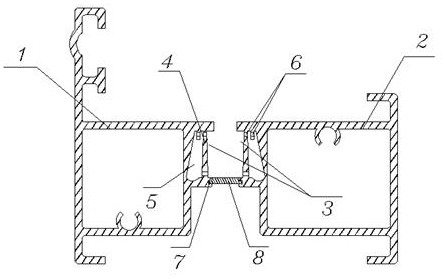

[0035] see Figure 1-2 , the casting method open tooth heat insulation aluminum profile is composed of left aluminum profile 1 and right aluminum profile 2 processed at one time, and the inner side of the left aluminum profile 1 and the right aluminum profile 2 are provided with two components for pouring In the pouring tank 3 of polyurethane, a limit groove 5 is arranged inside the inner wall of the left aluminum profile 1 and the right aluminum profile 2, and a partition 4 is arranged between the limit groove 5 and the pouring tank 3, and the top of the limit groove 5 is set There are protrusions, and a mounting groove 7 is provided under the inner side of the left aluminum profile 1 and the right aluminum profile 2, and a support plate 8 is placed in the mounting groove 7;

[0036] The molding method of the toothed heat-insulating aluminum profile by the pouring method includes the following steps:

[0037] S1: Preliminary forming of heat-insulating aluminum profiles, extr...

Embodiment 2

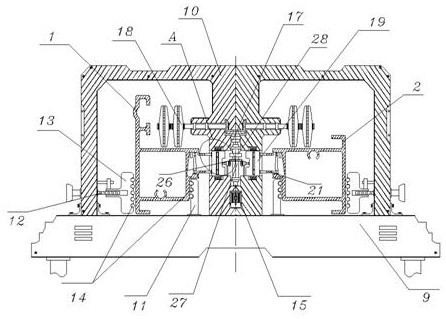

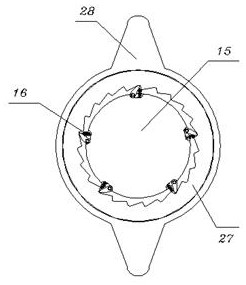

[0041] see Figure 1-7 , the gear opening device in the above step S2 includes a base 9, the top of the base 9 is fixed with a gear opening frame 10, and the inner cavities on both sides of the gear opening frame 10 are provided with positioning rods 11, and the positioning rods 11 are fixed on the base 9 On the upper end face of the open gear rack 10, a screw 12 is installed through the bearing on both sides, and the upper limit of the screw 12 is sleeved with a fixed rod 13, and the opposite sides of the fixed rod 13 and the positioning rod 11 are embedded with balls 14. The left aluminum profile 1 and the right aluminum profile 2 are placed in the inner cavities on both sides of the rack 10 respectively, and the left aluminum profile 1 and the right aluminum profile 2 are located between the positioning rod 11 and the fixing rod 13; the motor 15 It is embedded and fixed in the middle of the open-gear frame 10, and the top position of the output shaft of the motor 15 is slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com