Self-adaptive intelligent material moving device of laser cutting machine

A laser cutting machine, self-adaptive technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problem that the finished product cannot be discharged in time, affecting the normal cutting function of the laser cutting machine, etc., to reduce technical requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

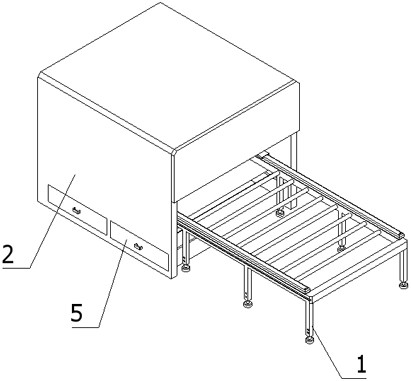

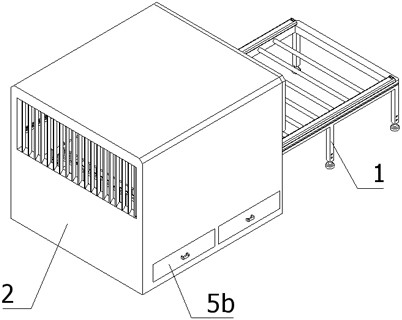

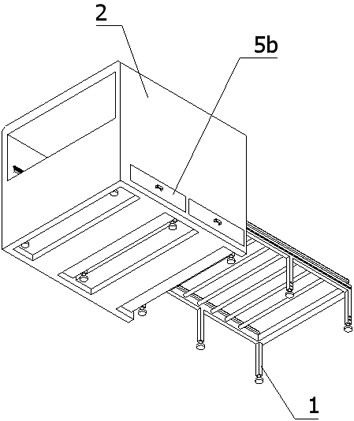

[0044] like Figure 1-15 As shown, this application provides:

[0045]An adaptive intelligent moving device for a laser cutting machine, comprising a base 1, a casing 2, a feeding device 3, a cutting device 4, a collecting mechanism 5 and a sliding table 6; the feeding device 3 is arranged on the sliding table 6, and the feeding The device 3 includes a receiving rod 3a, a supporting member 3b, a rotating shaft 3c, a connecting component 3d, a roller 3e, a driving component 3f and a placing component 3g; the placing component 3g is arranged on the upper part of the sliding table 6; The receiving rods 3a are slidably arranged on the sliding table 6 in sequence along the length direction of the sliding table 6. The leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com