Inflatable rubber tire, framework and plug device for pipe coating

A rubber tire and skeleton technology, applied in the direction of surface layering devices, ceramic molding machines, manufacturing tools, etc., can solve problems such as deterioration of plugging devices, low efficiency, corrosion, etc., to prevent the deterioration of the working environment, reduce labor costs, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

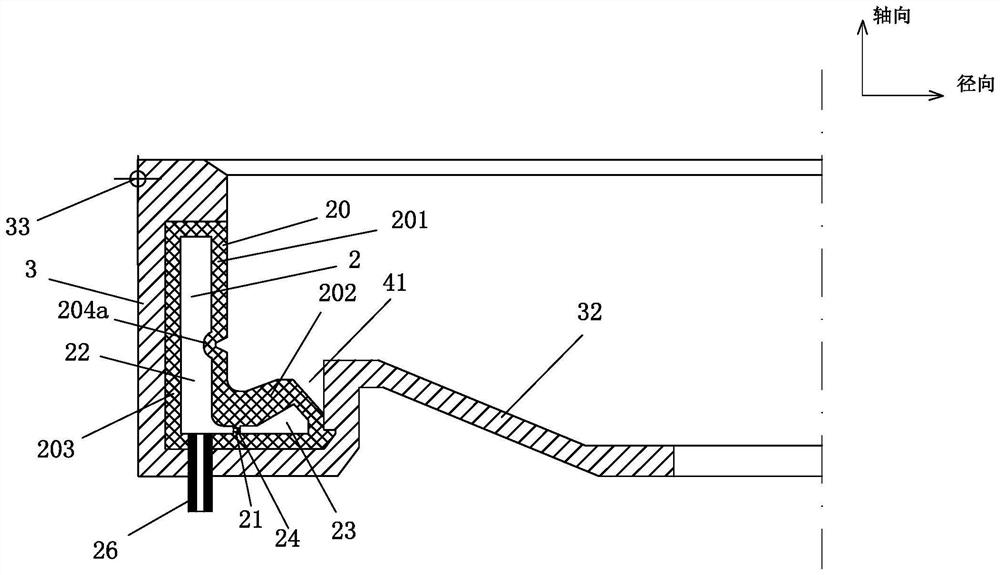

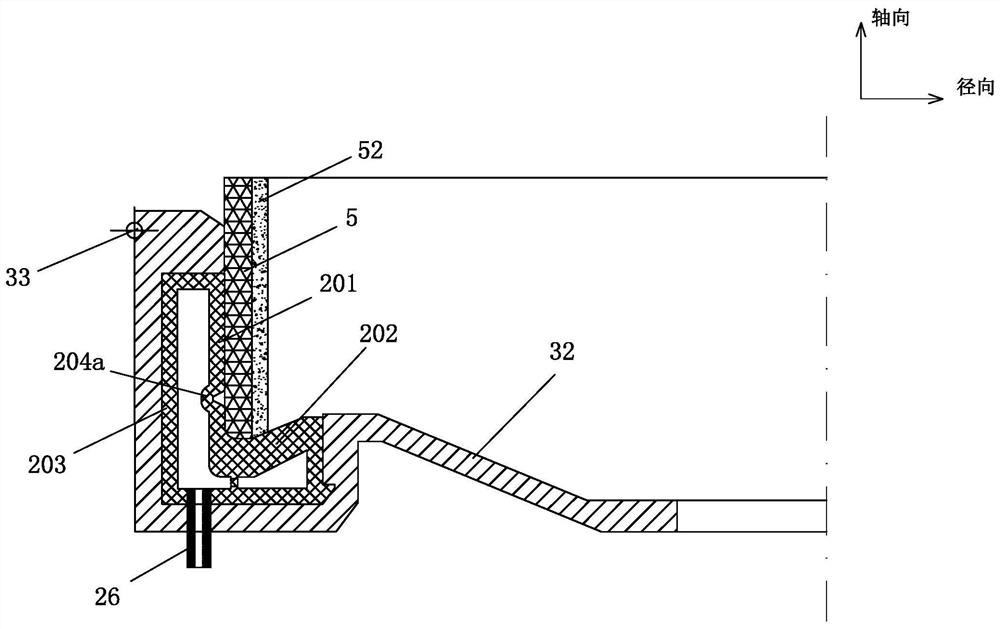

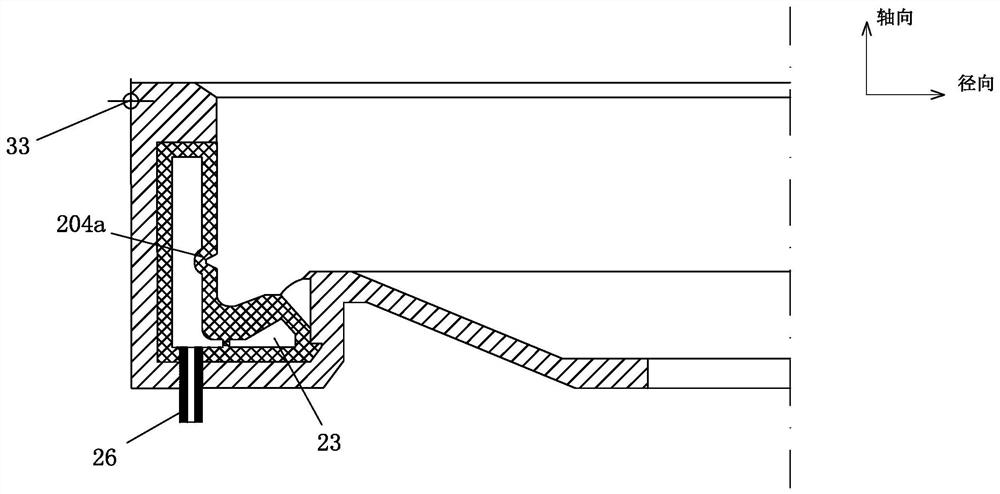

[0025] Some possible embodiments of the present application are described below with reference to the accompanying drawings. It is noted that the figures are not drawn to scale. Some details may be exaggerated for clarity of presentation, and some details not necessarily shown have been omitted.

[0026] It should be noted that, in this application, the terms "axial" and "radial" are defined relative to the direction of the casting pipe, which is oriented with the central axis of the casting pipe. The use of "axial" and "radial" is descriptive (meaning only the relative orientation of the components) and not limiting in any way (ie, not referring to a particular direction). The terms "axially inboard", "axially inwardly" refer to the direction towards the casting tube. The terms "radially inward", "radially inward" refer to the direction towards the axis of the cast tube.

[0027] like figure 1 As shown, the present application discloses a partial cross-sectional view of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com