Improved centerless indentation cutting device

An improved indentation technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of high manufacturing cost of a single part, large radius of centerless sawtooth, high replacement frequency, etc., to reduce production and maintenance costs, The effect of low production cost and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

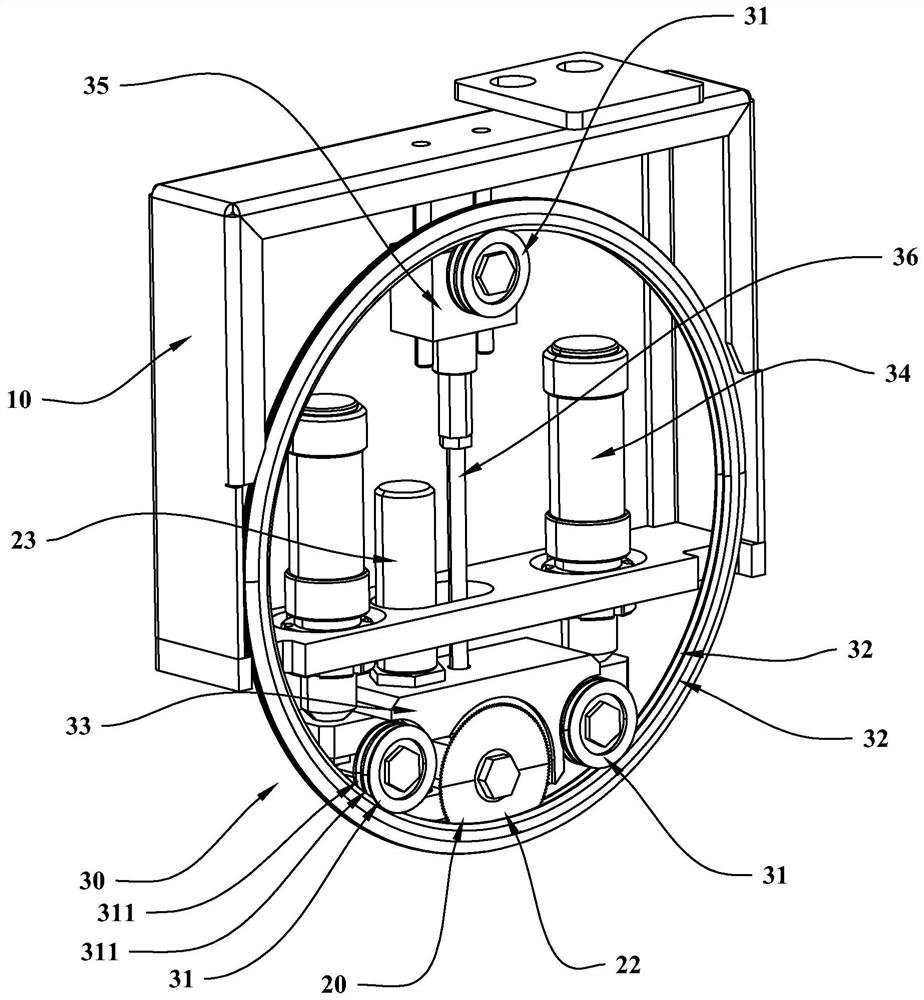

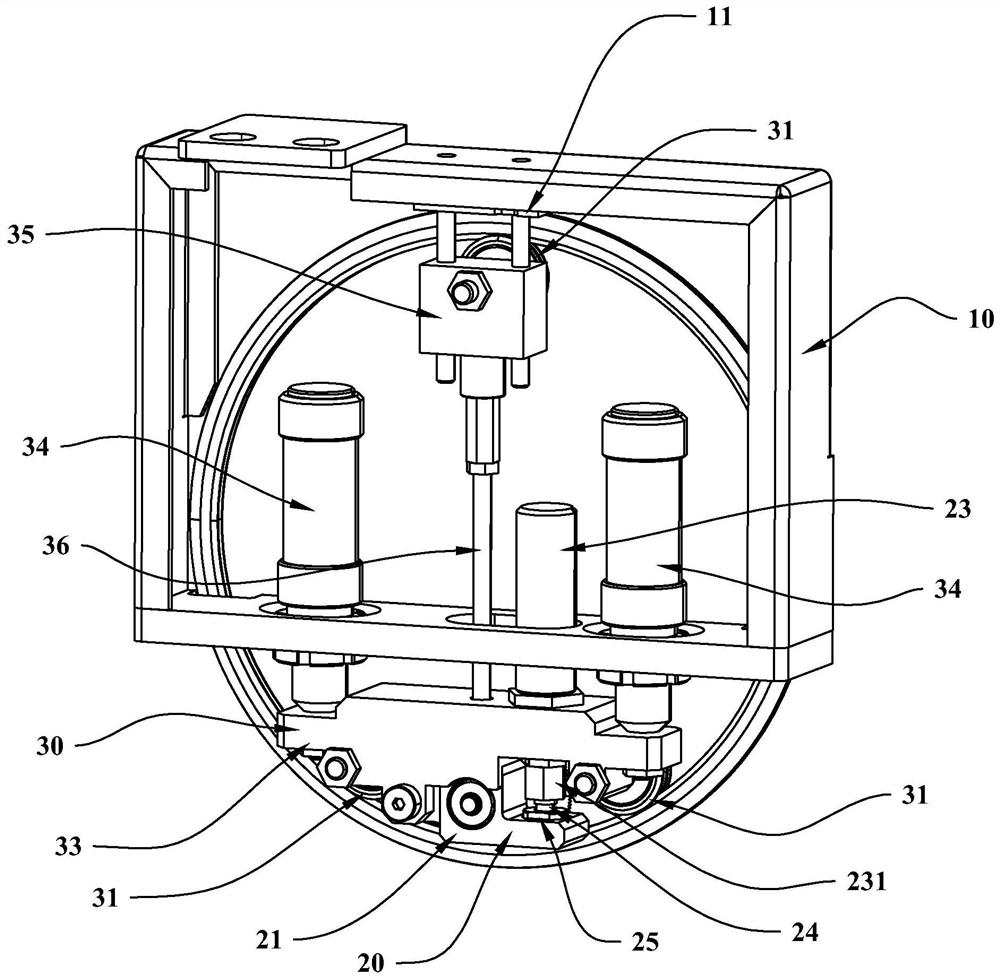

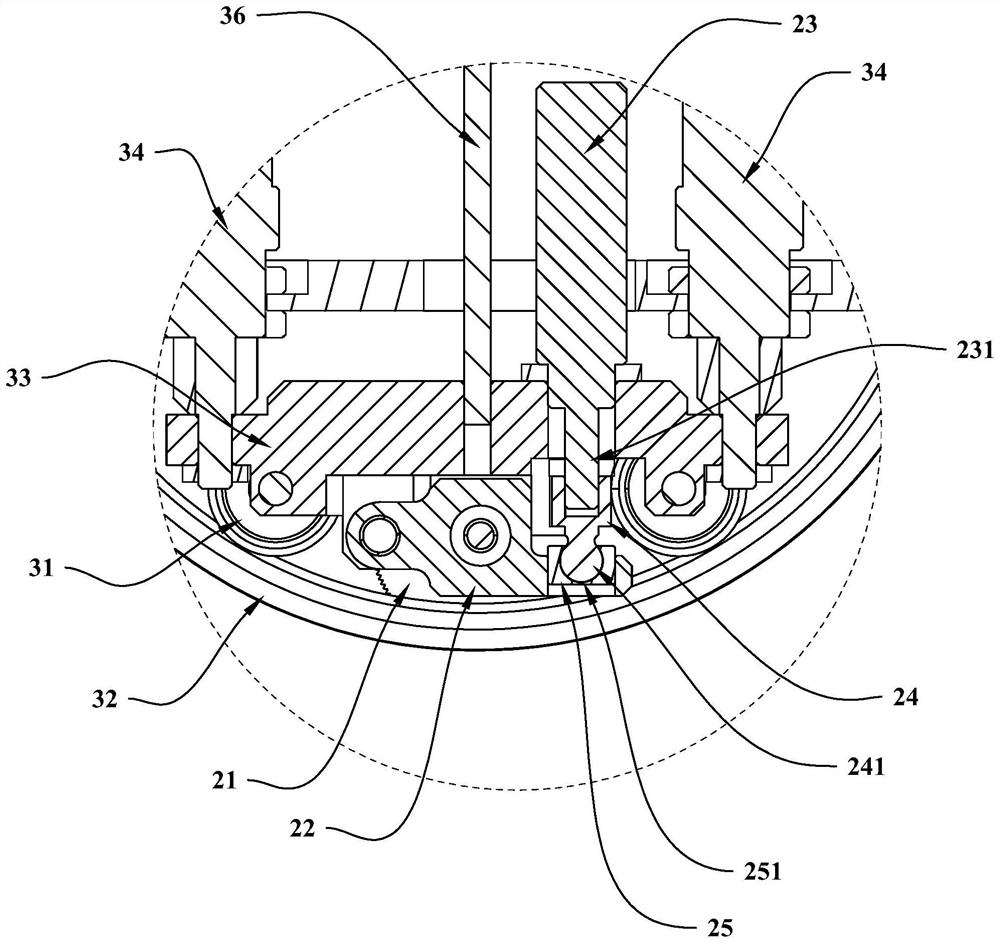

[0028] refer to Figure 1 to Figure 3 , An improved centerless indentation cutting device proposed by the present invention includes a mounting frame 10, a cutting mechanism 20 and an indentation mechanism 30, and the indentation mechanism 30 includes a number of rolling wheels 31 and an indentation wheel 32; 32 is arranged at two annular intervals, and the rolling wheel 31 can abut the inner ring of the creasing wheel 32;

[0029] The cutting mechanism 20 includes a cutting movable seat 21 and a cutting saw wheel 22 installed on the cutting movable seat 21; the cutting saw wheel 22 is located between the interval grooves of the two creasing wheels 32; the cutting movable seat 21 can be opposite to The creasing wheel 32 moves so that the cutting saw wheel 22 extends beyond the outer circumference of the creasing wheel 32 .

[0030] In the present invention, the indentation wheel 32 is a centerless annular ring wheel structure, and two are arranged at intervals. Between the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com