Industrial enzyme quantitative feeding equipment

An equipment and industrial technology, applied in the field of industrial enzyme preparation, can solve the problems of increasing the sliding resistance of the discharge conduit, blockage of the discharge conduit, and difficulty in realizing quantitative feeding of materials, and achieves the effect of promoting flow contact and promoting uniform tiling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

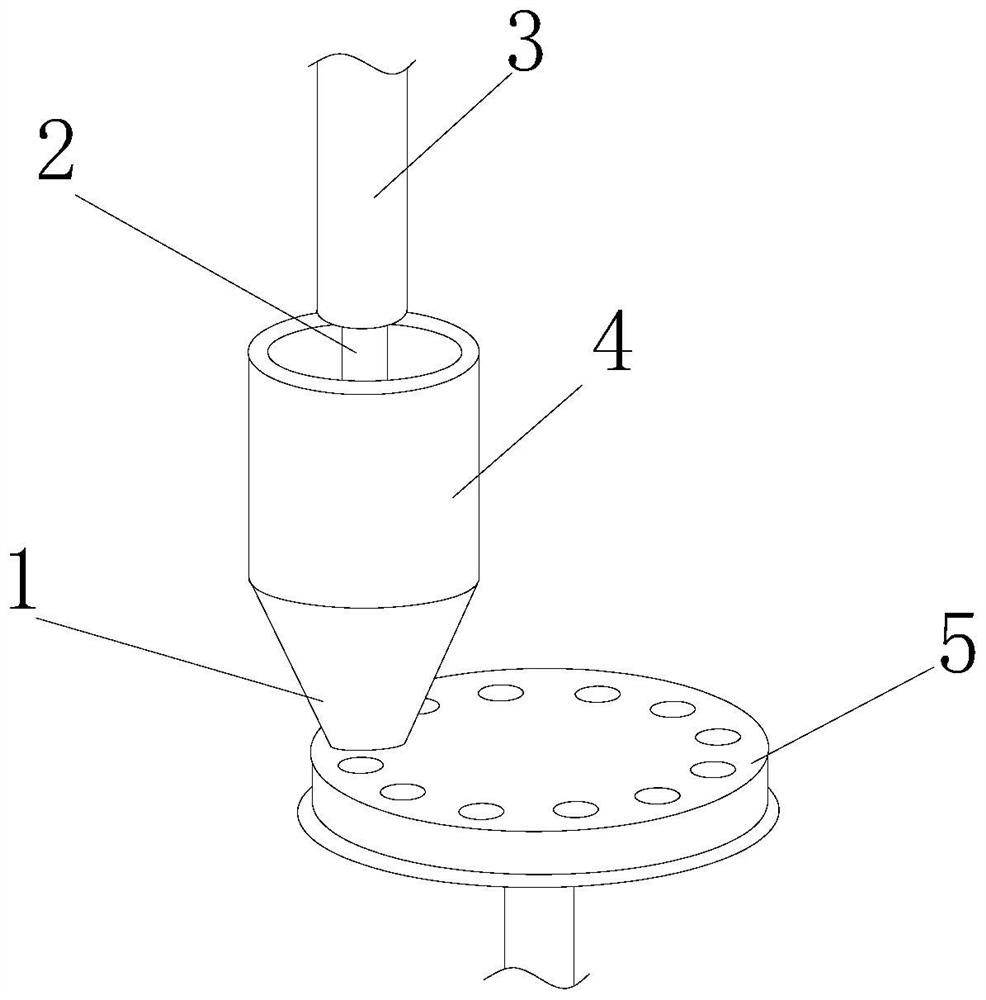

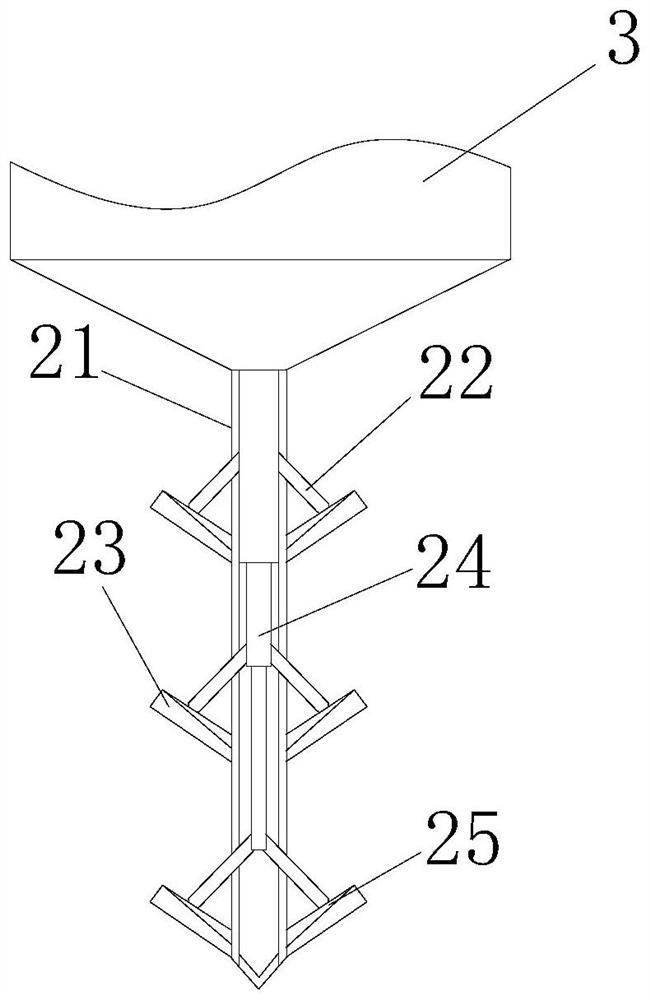

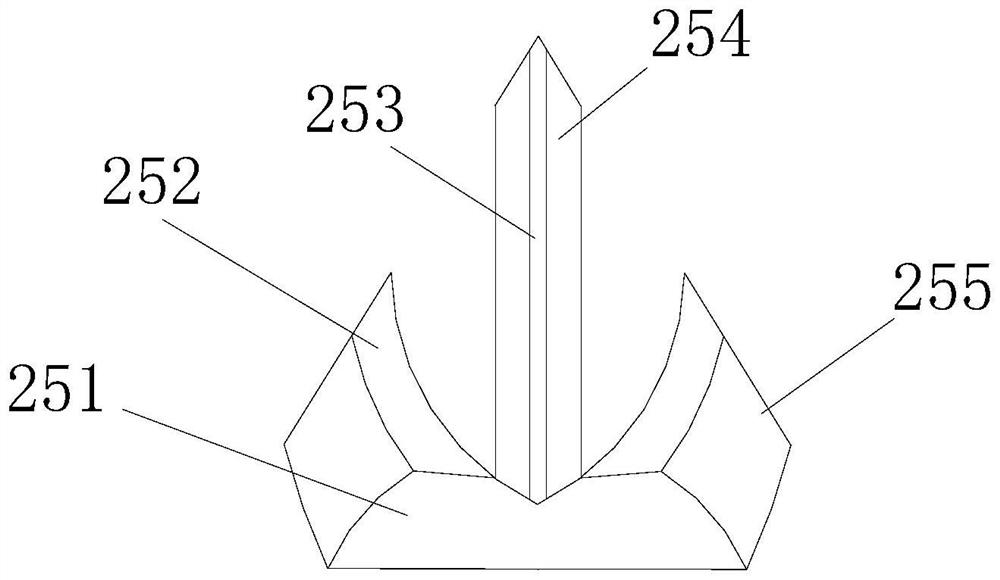

Embodiment 1

[0027] like Figure 1-Figure 3 It shows that the invention provides a type of industrial enzyme -volume distribution equipment. Its structure includes bucket 1. Materials inlet, activity rod 3, turntable 4, mobile disk 5, which is transitioned through the cylinder 4 and the mobile disk 5 transitional transition. Cooperation, the inlet part of the activity rod 3 is set in the tube 4 with the input parts 2, which includes the built -in cavity 21, the discharge catheter 22, the diversion rod 23, the telescopic rod 24, and auxiliary parts 25. Built -in cavity 21 welded connection on the activity rod 3, and the central part is fixed with telescopic rod 24. The expansion rod 24 is connected to the discharged custody 22 through the internal cavity 21. Direct rod 23 indirect cooperation, the auxiliary parts 25 include the conversion device 251, the push structure 252, the main axis 253, the side road 254, and the division plate 255. 23 The bottom is inserted and connected together, and the...

Embodiment 2

[0029] like Figure 4-Figure 7 According to the embodiment 1, the present invention combines the cooperation of the following structural components, which includes the transformation device 251 including the running layer 51A1, the adjustment part 51A2, and a shaft seat 51A3. On the seat 51A3, and there is a tuned parts 51A2 indirectly with the side lane 254, the axis 51A3 is a stone mortar -shaped structure, the arc -shaped outer welding connection and the sub -plate 255, and the transition in the middle slot structure is combined with the main axis 253 Provide paths for side road 254 turning twisting, the tune parts 51A2 include concave card A21, folding wings A22, sliding rail A23, backward row A24, and block A25. On the running layer 51A1, and the block A25 hinge is connected to a folding A22, the block A25 is fixed on the side of the slide rail A23. Structural 252 includes splint 52B1, inner groove 52B2, compartment 52B3, and inducer 52B4. 52B2 indirect cooperation with the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com