Tire repair liquid with high discrimination degree and preparation method thereof

A technology of tire repair fluid and solution, applied in the field of tire repair fluid, can solve problems such as hidden safety hazards in driving, difficulty in identifying tire repair conditions, and inability to intuitively judge tire repair, achieving high recognition and eliminating hidden dangers of driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

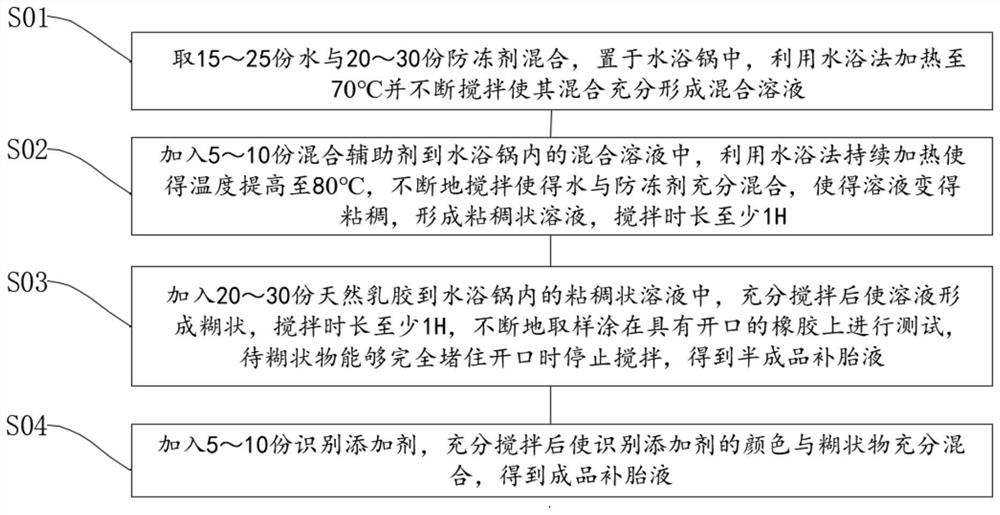

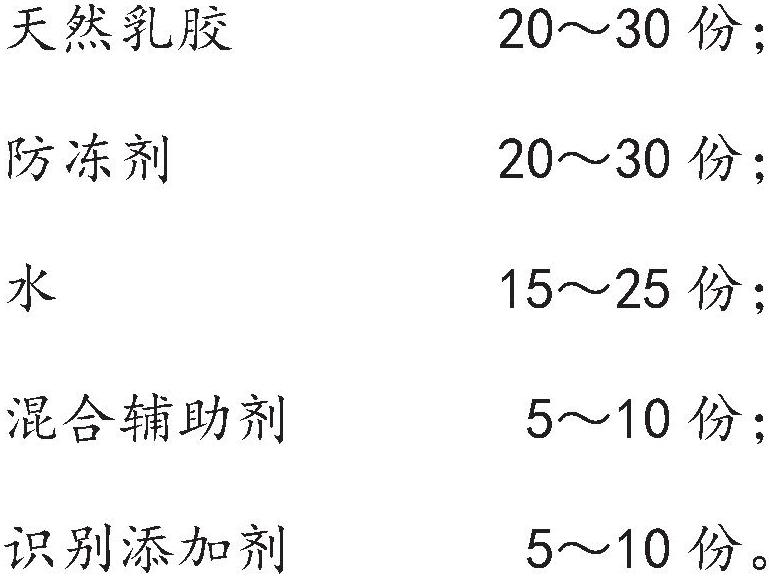

[0027] S01: Mix 15 parts of water with 20 parts of antifreeze, put it in a water bath, heat it to 70°C by the water bath method and keep stirring to make it fully mixed to form a mixed solution;

[0028] S02: Add 5 parts of mixing adjuvant to the mixed solution in the water bath, use the water bath method to continue heating to increase the temperature to 80°C, that is, 2 parts of gelling agent and 3 parts of emulsifier, and keep stirring to make water and antifreeze sufficient. Mix to make the solution viscous and form a viscous solution, stirring for at least 1H;

[0029] S03: Add 20 parts of natural latex to the viscous solution in the water bath, fully stir the solution to form a paste, the stirring time is at least 1H, and continuously sample and apply it to the rubber with openings for testing. Stop stirring when the opening is completely blocked to obtain semi-finished tire repair fluid;

[0030] S04: Add 5 parts of identification additives, that is, 5 parts of fluores...

Embodiment 2

[0034] S01: Mix 25 parts of water with 30 parts of antifreeze, put it in a water bath, and heat it to 70°C by the water bath method and keep stirring to make it fully mixed to form a mixed solution;

[0035] S02: Add 10 parts of mixing adjuvants to the mixed solution in the water bath, use the water bath method to continue heating to increase the temperature to 80°C, that is, 5 parts of gelling agent and 5 parts of emulsifier, and keep stirring so that water and antifreeze are fully Mix to make the solution viscous and form a viscous solution, stirring for at least 1H;

[0036] S03: Add 30 parts of natural latex to the viscous solution in the water bath, fully stir the solution to form a paste, the stirring time is at least 1H, and continuously sample and apply it to the rubber with openings for testing. Stop stirring when the opening is completely blocked to obtain semi-finished tire repair fluid;

[0037] S04: Add 10 parts of identification additives, that is, 10 parts of f...

Embodiment 3

[0039] S01: Mix 20 parts of water with 25 parts of antifreeze, put it in a water bath, heat it to 70°C by the water bath method and keep stirring to make it fully mixed to form a mixed solution;

[0040] S02: Add 7 parts of mixing adjuvant to the mixed solution in the water bath, and use the water bath method to continue heating to increase the temperature to 80°C, that is, 3 parts of gelling agent and 4 parts of emulsifier, and keep stirring to make water and antifreeze sufficient. Mix to make the solution viscous and form a viscous solution, stirring for at least 1H;

[0041] S03: Add 25 parts of natural latex to the viscous solution in the water bath, fully stir the solution to form a paste, the stirring time is at least 1H, and continuously sample and apply it to the rubber with openings for testing. Stop stirring when the opening is completely blocked to obtain semi-finished tire repair fluid;

[0042] S04: Add 7 parts of identification additives, namely 7 parts of fluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com