Prefabricated segment bridge joint structure and construction method

A technology for bridges and segments, which is applied in the joint structure and construction of prefabricated segmental bridges, which can solve the problems of easy shearing of concrete shear keys, fragility of concrete shear keys, and damage of shear keys, etc., so as to solve the problem of shear resistance Insufficient, simple structure, shear resistance and ductility improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

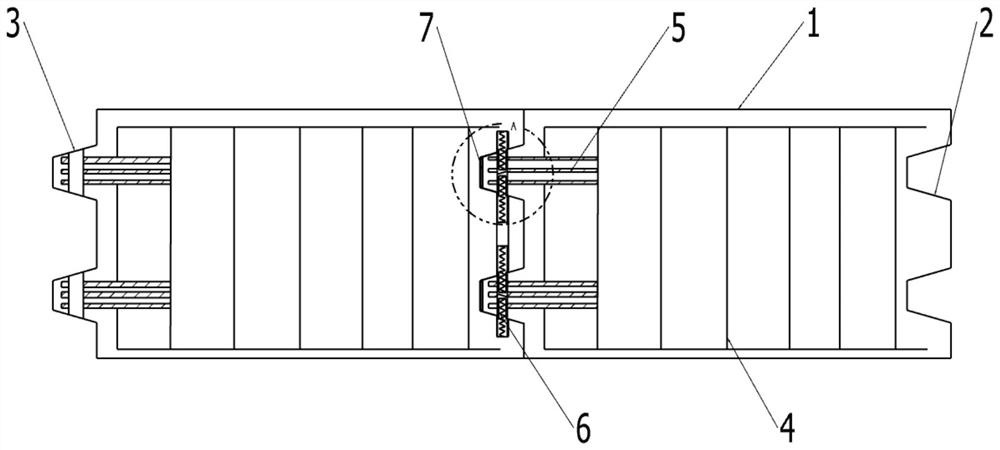

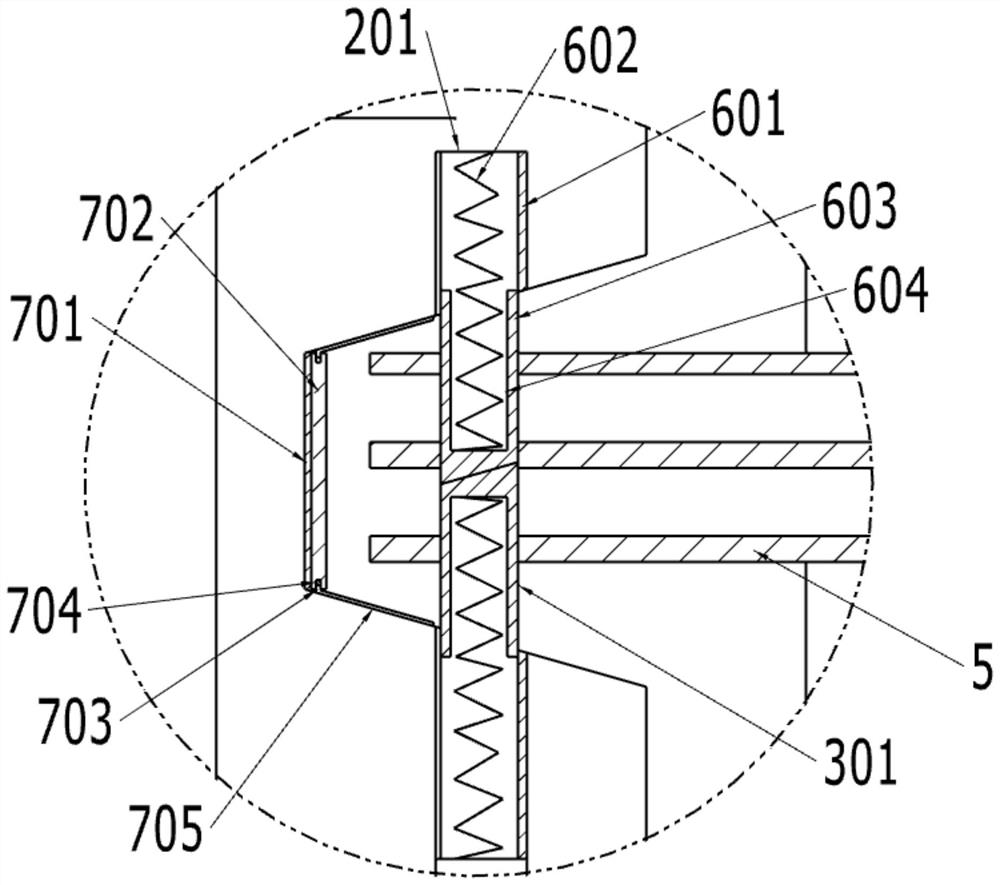

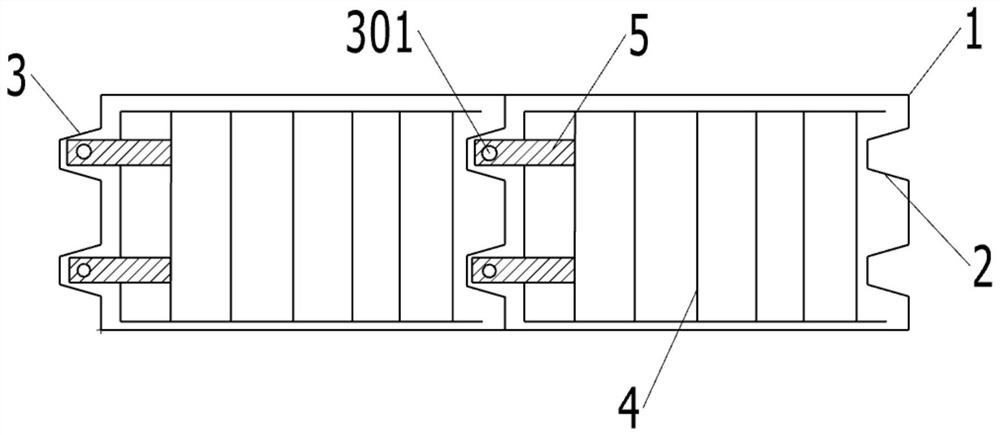

[0045] see Figure 1 to Figure 8 , The present invention provides a prefabricated segment bridge joint structure, comprising: a bridge prefabricated segment 1, a steel skeleton 4, a strip steel plate 5, one end of the bridge prefabricated segment 1 is provided with a trapezoidal shear concave key 2, the The end of the bridge prefabricated segment 1 away from the trapezoidal shear concave key 2 is provided with a trapezoidal shear convex key 3 that cooperates with the trapezoidal shear concave key 2; the steel skeleton 4 is installed inside the bridge prefabricated segment 1 ; The strip steel plate 5 is fixedly installed on the reinforced frame 4, and one end of the strip steel plate 5 extends into the trapezoidal shear convex key 3; a trapezoidal shear concave on the bridge prefabricated segment 1 The key 2 is connected with the trapezoidal shear convex key 3 on the other bridge prefabricated segment 1 through a clamping mechanism 6. The clamping mechanism 6 includes: a hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com