Boss and pit combined type blade air film cooling hole structure

A combined technology of air film cooling, applied in the direction of supporting elements of blades, climate sustainability, sustainable transportation, etc., can solve the problem of limited expansion of cooling air film, inability to effectively suppress the rise of cooling air flow, and inability to effectively control the mainstream and Cooling flow interaction and other issues to achieve the effect of increasing lateral coverage and suppressing lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

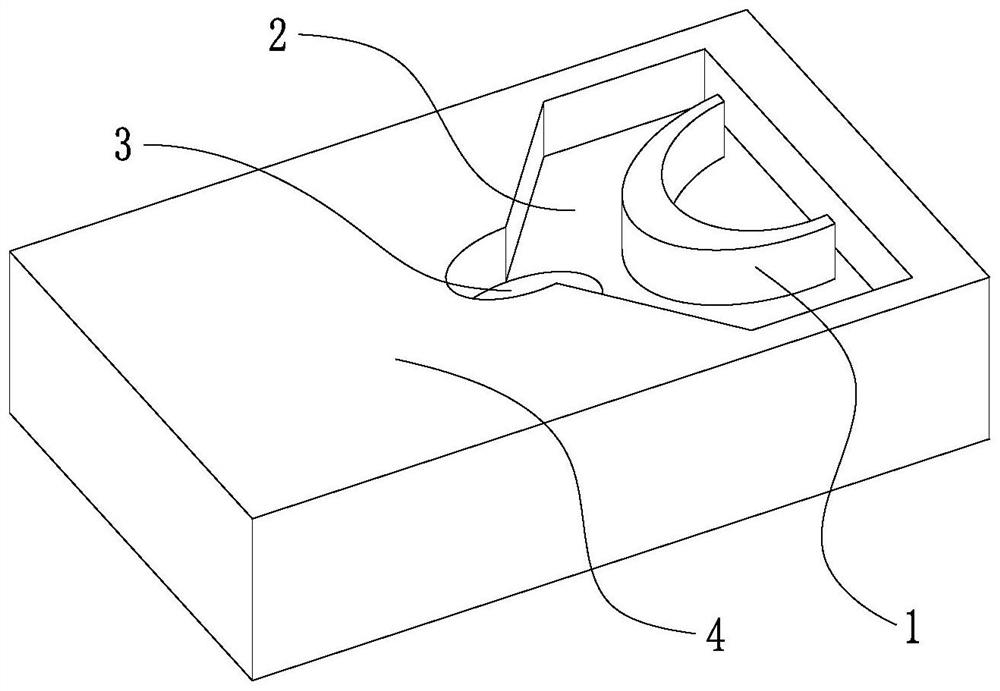

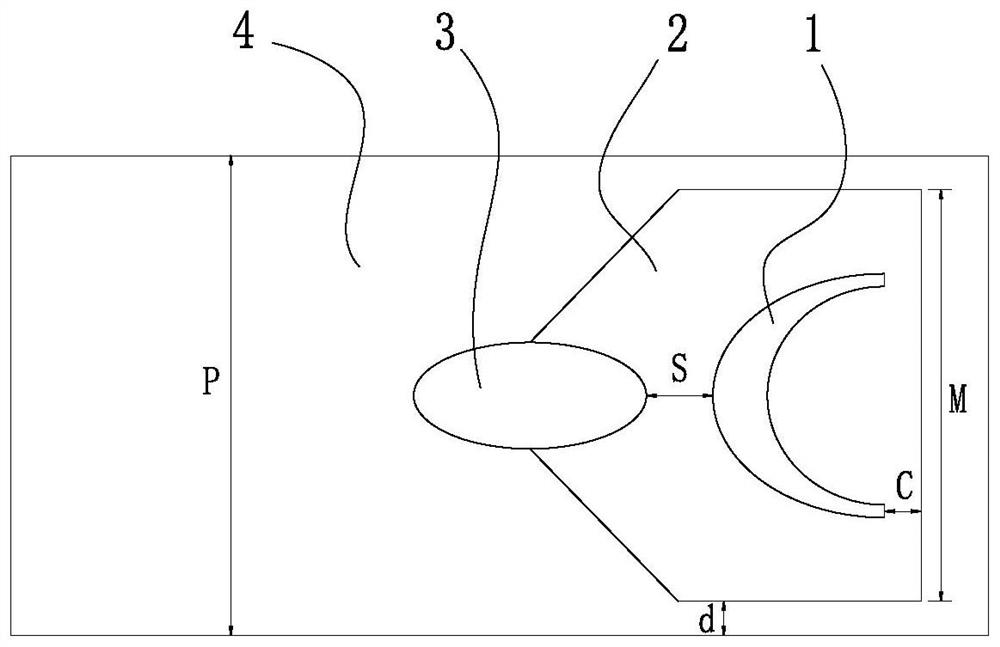

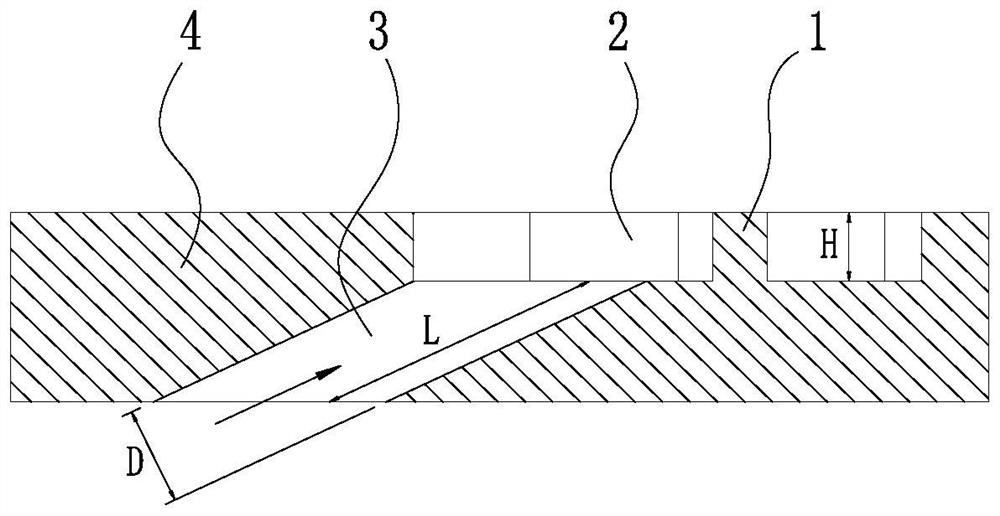

[0022] like Figures 1 to 3 As shown in the figure, a blade air film cooling hole structure combined with a boss and a pit includes a boss 1, a pit 2, a cylindrical hole 3 and a wall surface 4; the boss 1, the pit 2 and the cylindrical hole 3 are all provided with In the wall surface 4; the cylindrical hole 3 is communicated with the pit 2, and the outlet port of the cylindrical hole 3 is located on the bottom surface of the pit 2; the boss 1 is arranged in the pit 2, and the cylindrical hole The outlet port of 3 is directly opposite to the boss 1.

[0023] The centerlines of the boss 1 , the pit 2 and the cylindrical hole 3 are located in the same plane.

[0024] The height of the boss 1 is the same as the depth of the pit 2 .

[0025] The boss 1 is in the shape of a crescent as a whole, and the outlet port of the cylindrical hole 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com