Full-bore snap valve

A pull-off valve, full-bore technology, applied in the direction of lifting valves, valve devices, valve details, etc., can solve the problems of reducing the flow rate of loading and unloading, affecting work efficiency, obstructing media, etc., to facilitate installation and disassembly, and ensure work efficiency , Improve the effect of loading and unloading flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, but do not limit the rights thereof.

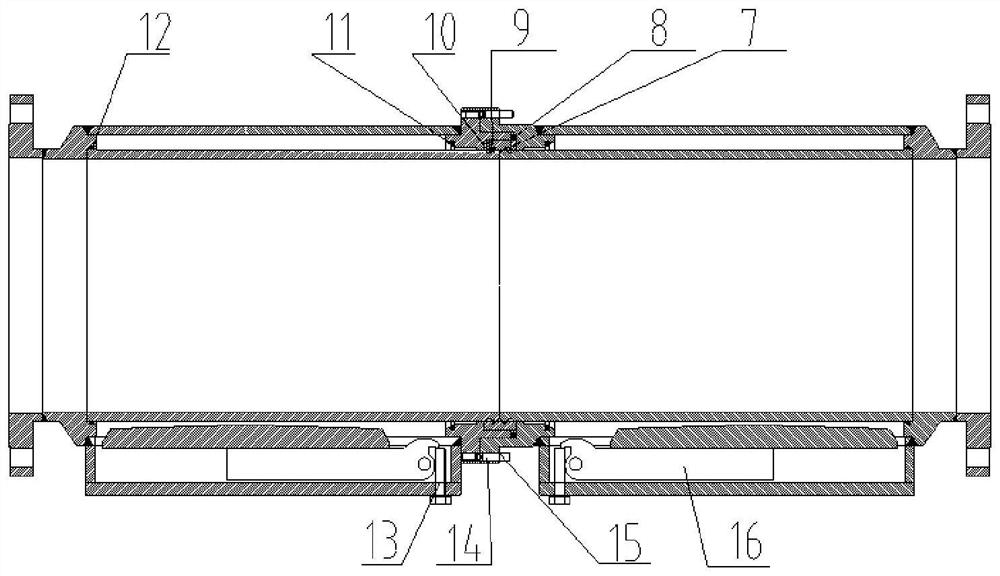

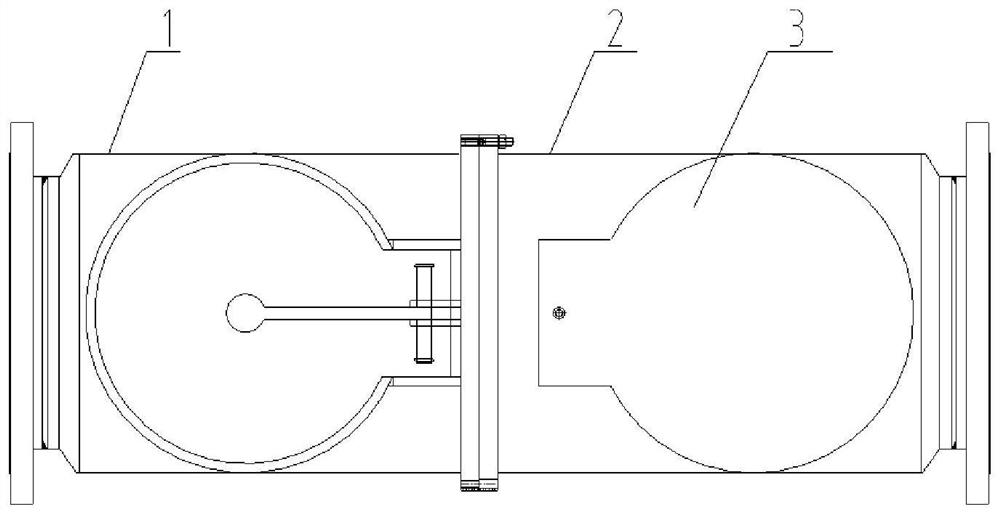

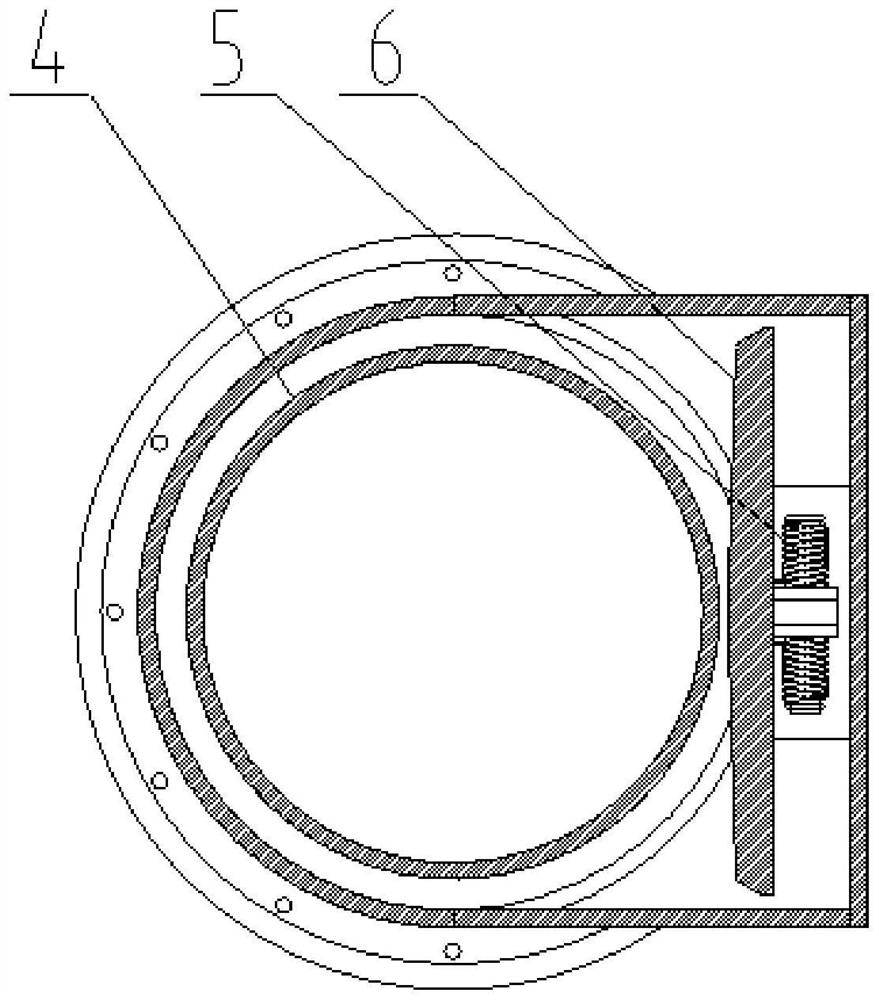

[0016] refer to Figure 1-Figure 3 , a full-bore pull-off valve, including two valve bodies installed in series on the pipeline, the connection of the valve bodies is provided with a butt flange 15, and the two valve bodies pass through a number of flanges installed along the circumferential direction. The two inner shells 4 are slidably installed inside the valve body to allow the medium to pass through unhindered, and a connecting sleeve 9 is installed at the connection between the two inner shells; Two rotary valve plate closing devices are arranged between the inner wall of the body and the outer wall of the inner casing for closing the pipe opening;

[0017] The rotary valve plate closing device includes a rotary valve plate 6 arranged in parallel with the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com