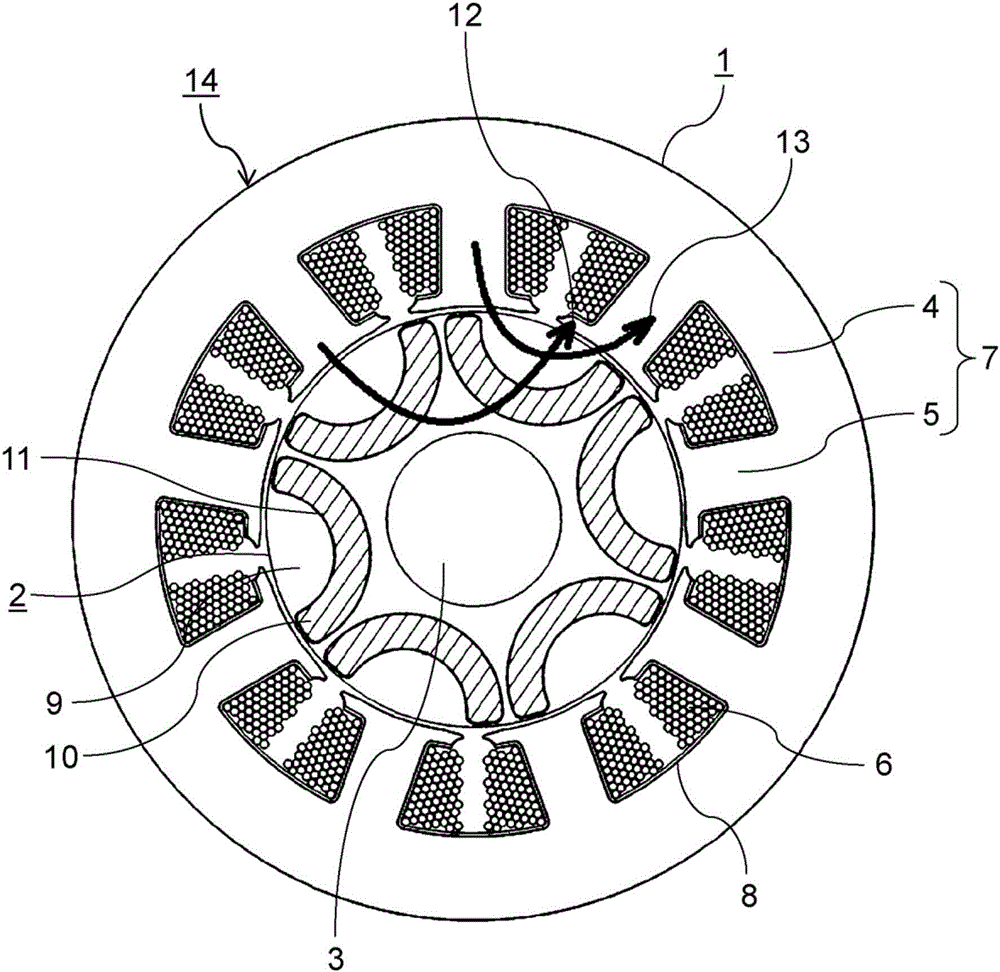

Electric motor element and electric motor

A technology of motors and components, applied in the direction of magnetic circuit rotating parts, inorganic material magnetism, magnetic circuit shape/style/structure, etc., can solve problems such as poor molding processes, and achieve high output effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] As the magnet powder constituting the bonded magnet, NdFeB-based magnet powder, SmFeN-based magnet powder, SmCo-based magnet powder, or the like can be used. One type of magnet powder may be used alone, or the above magnet powders may be used in combination. In order to be able to resist oxidation, it is better to use a coupling agent or a phosphoric acid coating to treat the surface of the magnet powder.

[0056] 96.5wt% of magnet powder, 3.0wt% of thermoplastic resin, and 0.5wt% of coupling agent were mixed, melted with a heating roll, kneaded and granulated to prepare magnet molding pellets. The roll temperature of the heating roll was set to 200°C.

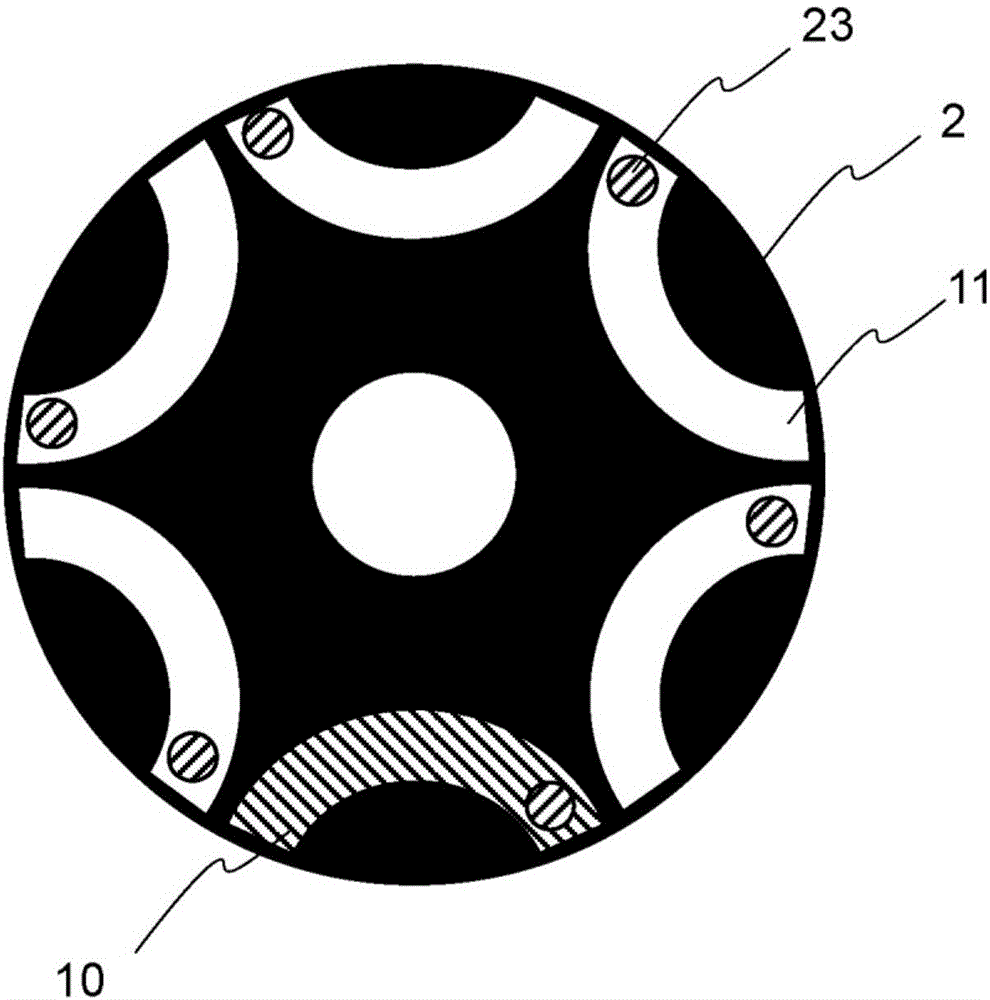

[0057] exist figure 2 Among them, the rotor 2 has a gate 23 near the outer peripheral portion of the end portion of the magnet arrangement hole 11 . Through the injection molding of the valve gate hot runner method, through the gate 23 to the figure 2 The magnet forming holes 11 provided inside the illustrated rot...

Embodiment 2

[0060] As the magnet powder constituting the bonded magnet, NdFeB-based magnet powder, SmFeN-based magnet powder, SmCo-based magnet powder, or the like can be used. One type of magnet powder may be used alone, or the above magnet powders may be used in combination. In order to be able to resist oxidation, it is better to use a coupling agent or a phosphoric acid coating to treat the surface of the magnet powder.

[0061] 96.5wt% of magnet powder, 3.0wt% of thermoplastic resin, and 0.5wt% of coupling agent were mixed, melted with a heating roll, kneaded and granulated to obtain pellets for magnet molding. The roll temperature of the heating roll was set to 200°C.

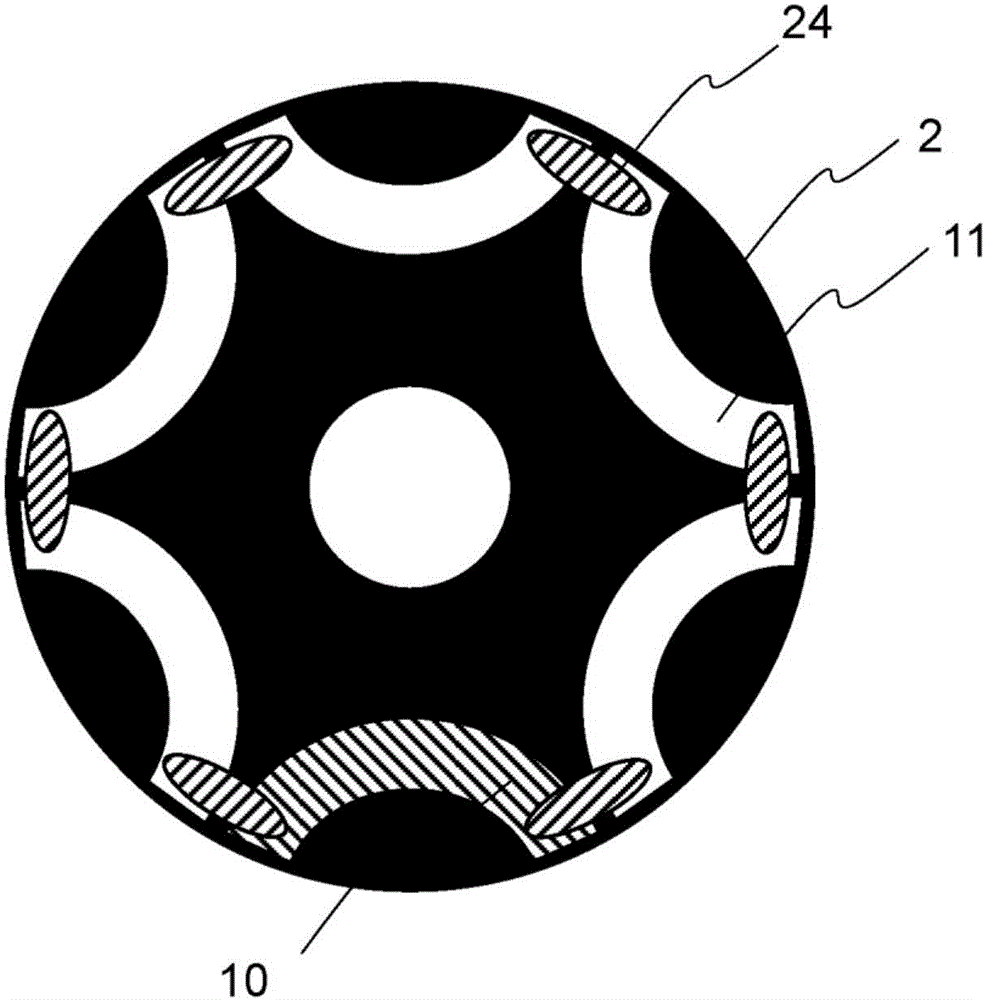

[0062] exist image 3 Among them, the rotor 2 has an elliptical gate 24 near the outer peripheral portion of the end portion of the magnet arrangement hole 11 . Through the injection molding of the valve gate hot runner method, through the gate 24 to the image 3 The magnet forming holes 11 provided inside the il...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com