Method and device for designing molded surface of valve rod of gas valve of solid attitude and orbit control engine

A design method and technology of attitude and orbit control, applied in the field of solid attitude and orbit control engine gas valve stem profile design, can solve problems such as poor design results and complicated profile design process, achieve stable design results and improve design efficiency , Guarantee the effect of linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to make the purposes, technical solutions and advantages of the embodiments of the present invention more clearly understood, the following will clearly illustrate the spirit of the disclosed contents of the present invention with the accompanying drawings and detailed description. Afterwards, changes and modifications can be made by the technology taught by the content of the present invention, without departing from the spirit and scope of the content of the present invention. The exemplary embodiments of the present invention and their descriptions are used to explain the present invention, but are not intended to limit the present invention.

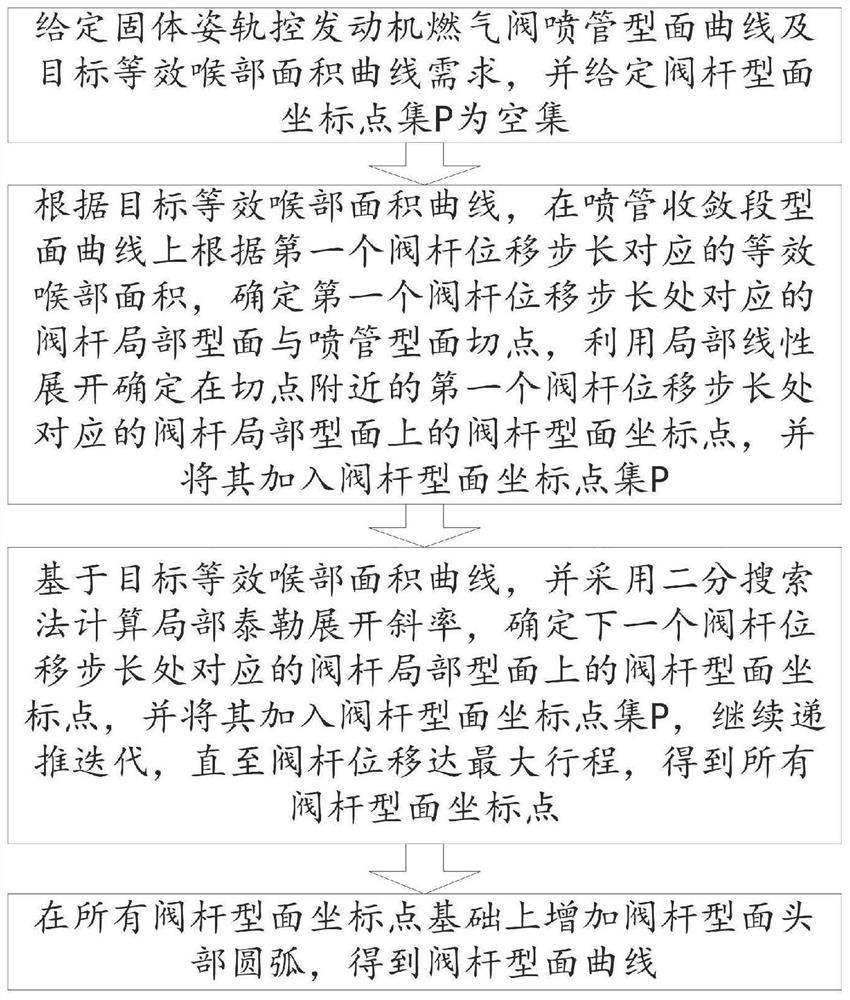

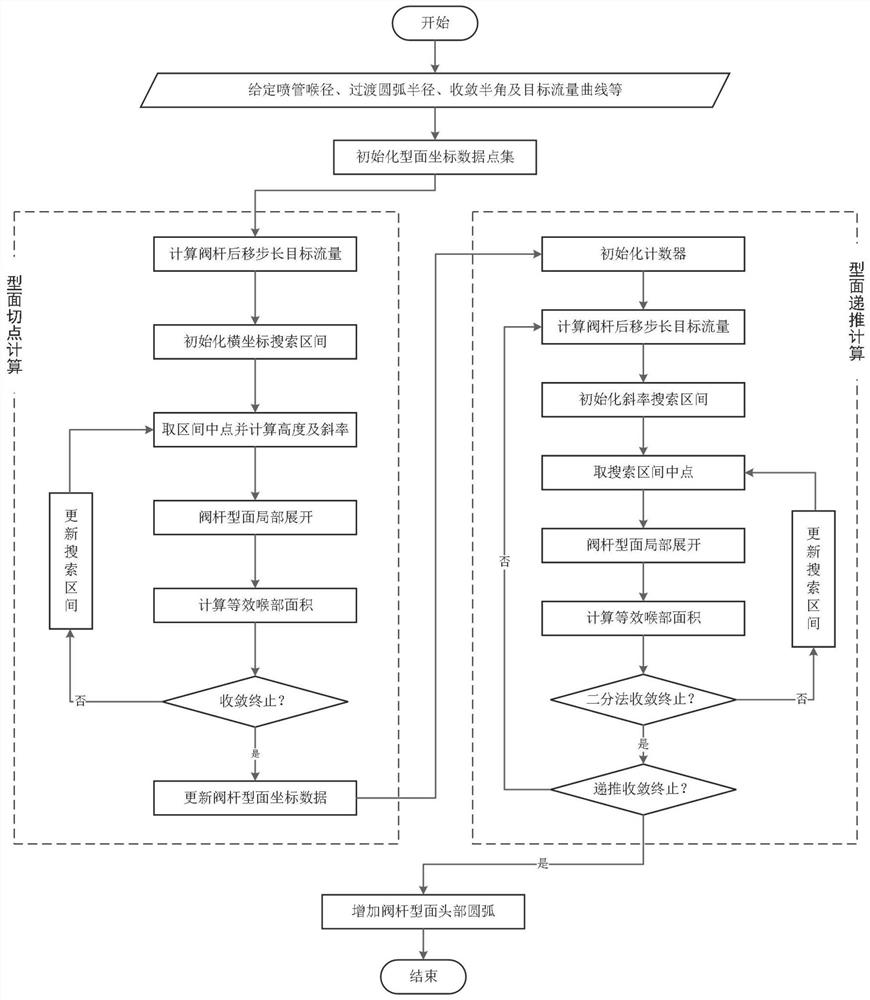

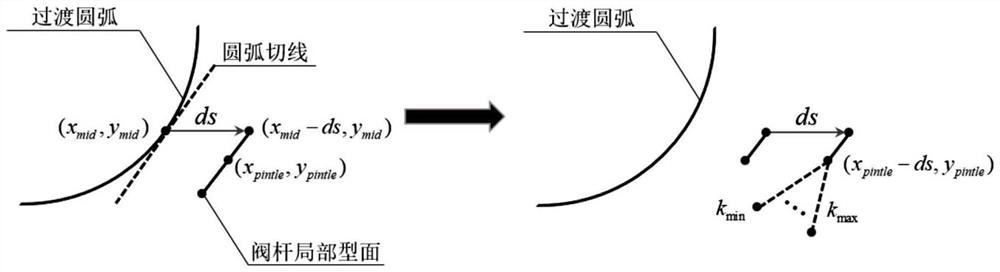

[0064] Aiming at the problem that it is difficult to realize the linear relationship between the valve stem displacement and the valve equivalent throat area height in the process of solid attitude control gas power valve profile design, the present invention proposes a linear flow regulating gas valve profile design m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com