Coated ternary material and application thereof

A ternary material and coating technology, applied in nanotechnology, electrical components, nanotechnology, etc. for materials and surface science, can solve the problems of DCR growth, thermodynamic instability, battery electrochemical performance degradation, etc., to achieve Good ionic conductivity and electronic conductivity, improved cycle stability and rate performance, and improved lattice compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

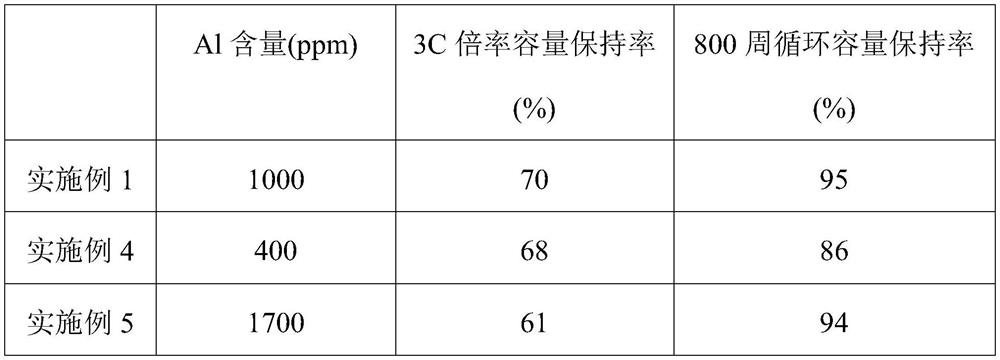

[0042] This embodiment provides a coated ternary material, and the core composition of the coated ternary material is LiNi 0.58 Co 0.11 Mn 0.31 O 2, the cladding layer is WAO material, and the WAO material is tungsten oxide-doped alumina;

[0043] Based on the mass of the clad ternary material, the mass percentage of the WAO material is 0.54 wt %, the content of the Al element is 1000 ppm, and the content of the W element is 2800 ppm;

[0044] In the WAO material, the mass ratio of Al element and W element is 1:3;

[0045] The preparation raw materials of the coated ternary material include ternary material a sintered product, WAO material and ethanol;

[0046] The preparation method of the coated ternary material comprises the following steps:

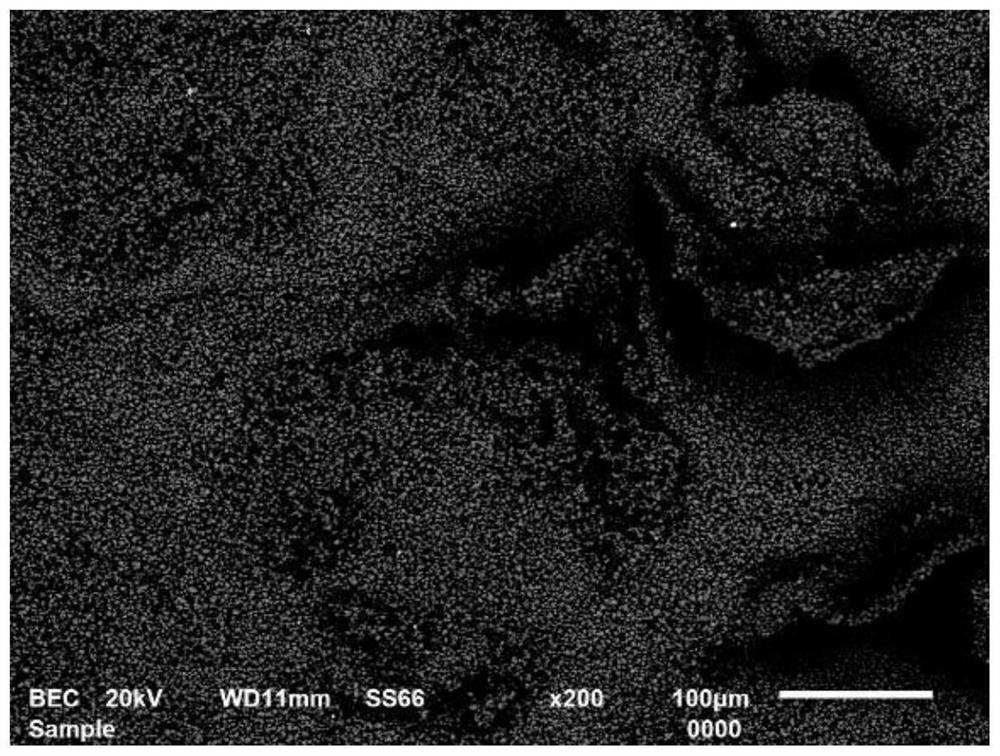

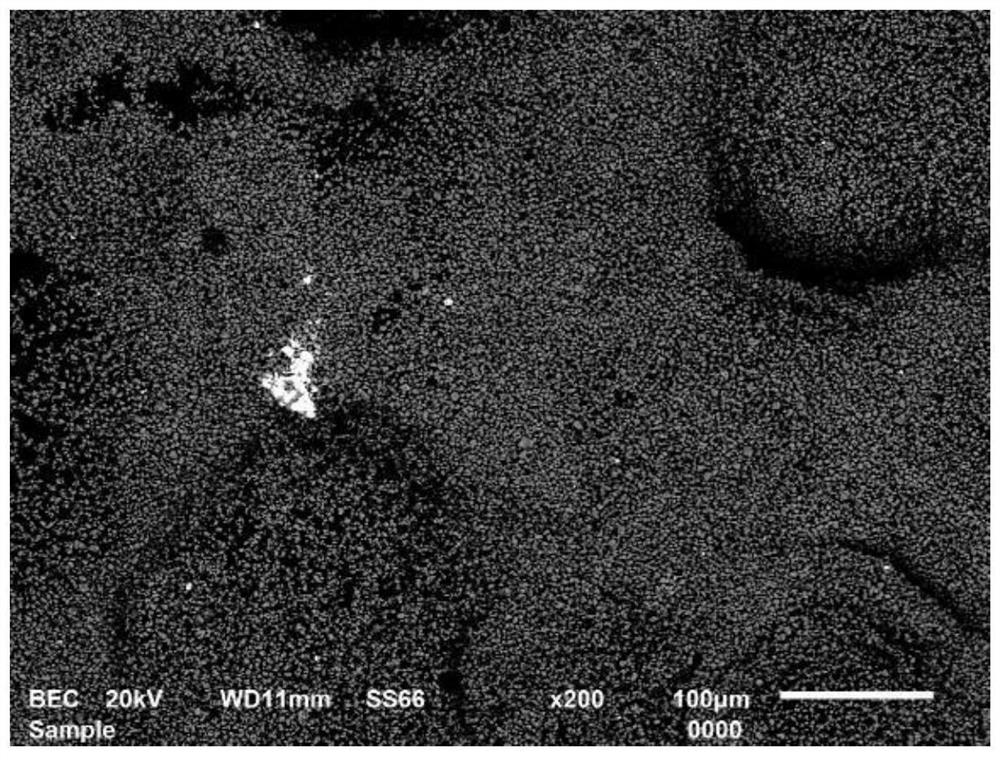

[0047] Mix the first sintered ternary material, WAO material and ethanol, stir to completely volatilize the ethanol, and then sinter the obtained mixture at 450 °C for 15 h to obtain the coated ternary material. The SEM image of ...

Embodiment 2

[0050] This embodiment provides a coated ternary material, and the core composition of the coated ternary material includes LiNi 0.6 Co 0.12 Mn 0.28 O 2 , the cladding layer is WAO material, and the WAO material is tungsten oxide-doped alumina;

[0051] Based on the mass of the cladding ternary material, the mass percentage of the WAO material is 0.3 wt %, the content of the Al element is 700 ppm, and the content of the W element is 1400 ppm;

[0052] In the WAO material, the mass ratio of Al element and W element is 1:2;

[0053] The preparation raw materials of the coated ternary material include ternary material a sintered product, WAO material and ethanol;

[0054] The preparation method of the coated ternary material comprises the following steps:

[0055] Mixing the first sintered product of ternary material, WAO material and ethanol, after stirring to completely volatilize the ethanol, the obtained mixture is sintered at 300°C for 18 hours to obtain the coated tern...

Embodiment 3

[0058] This embodiment provides a coated ternary material, and the core composition of the coated ternary material includes LiNi 0.58 Co 0.11 Mn 0.31 O 2 , the cladding layer is WAO material, and the WAO material is tungsten oxide-doped alumina;

[0059] Based on the mass of the coated ternary material, the mass percentage of the WAO material is 0.7 wt %, the content of the Al element is 1000 ppm, and the content of the W element is 4000 ppm;

[0060] In the WAO material, the mass ratio of Al element and W element is 1:4;

[0061] The preparation raw materials of the coated ternary material include ternary material a sintered product, WAO material and ethanol;

[0062] The preparation method of the coated ternary material comprises the following steps:

[0063] Mixing the first sintered ternary material, WAO material and ethanol, stirring to completely volatilize the ethanol, and sintering the obtained mixture at 600°C for 10 hours to obtain the coated ternary material; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com