Automatic wire-stripping crimping tubular terminal machine

An automatic wire stripping and crimping tube technology, which is applied in connection, electronic waste recycling, circuit/collector components, etc., can solve the problems of low work efficiency, high scrap rate, high cost, etc., to reduce the transportation link and reduce the volume , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

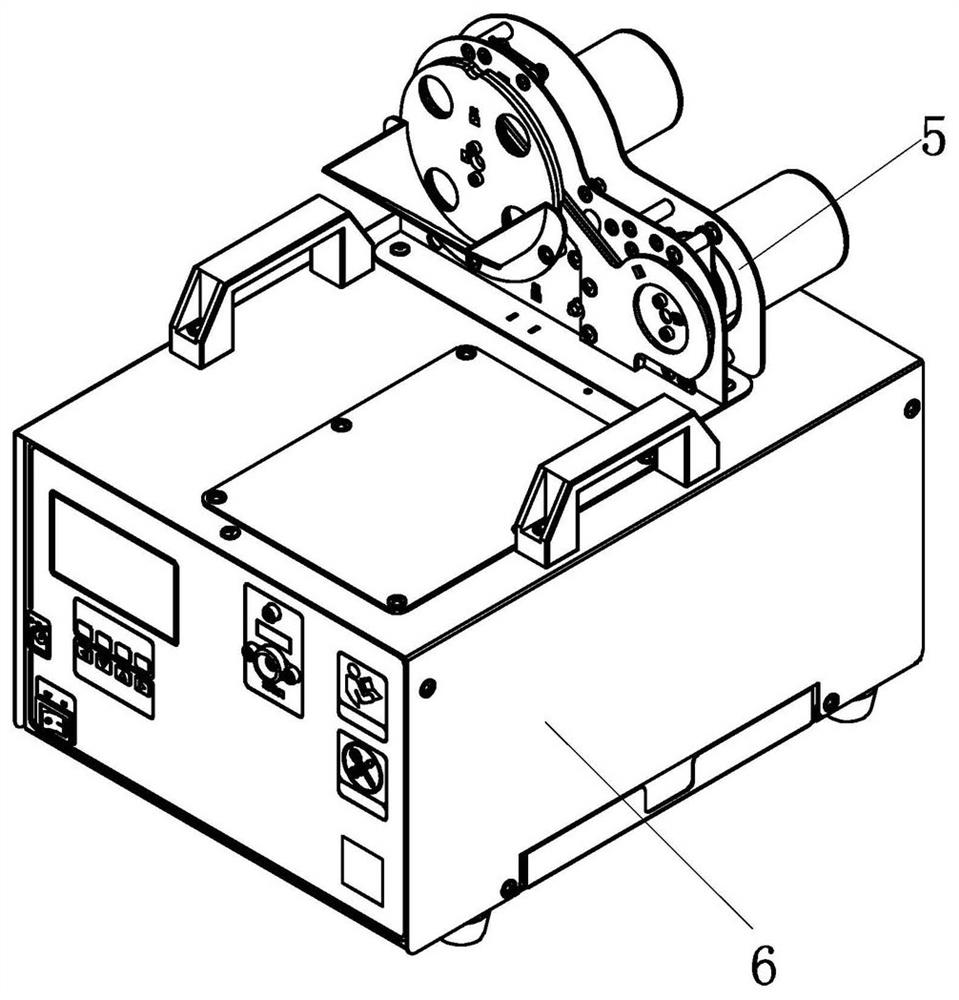

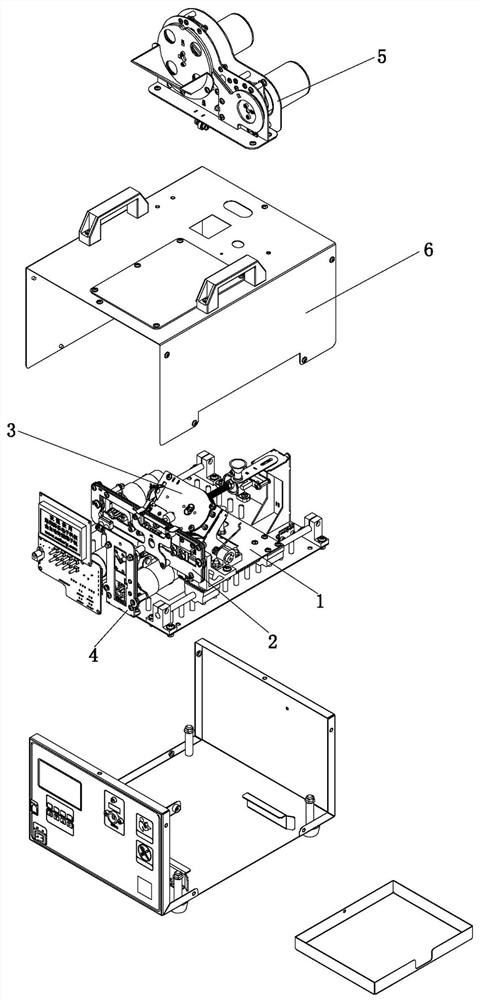

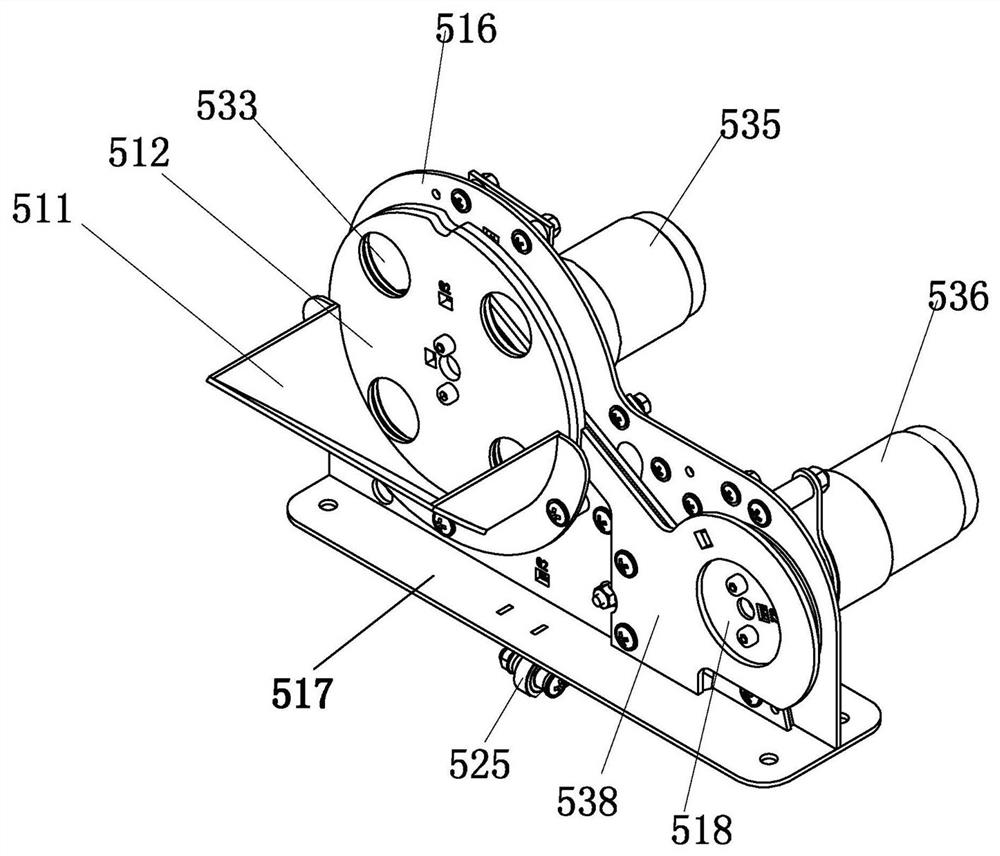

[0025] Depend on Figure 1 to Figure 17 Given, an automatic wire stripping and crimping tube type terminal machine includes a housing 6, and the housing 6 is provided with a wire clamping mechanism 4, a sliding platform 1, a wire stripping harness mechanism 2 and a crimping mechanism 3 in sequence from left to right. , a terminal feeding mechanism 5 is fixed on the casing 6, the blanking port of the terminal feeding mechanism 5 is located in the casing 6, the wire stripping mechanism 2 is fixed on the sliding platform 1, and the clamping mechanism 3 is rotatably connected with the sliding platform 1 , the crimping mechanism 3 has two states: horizontal and vertical, the crimping mechanism 3 is used to fix the tubular terminal fed by the terminal feeding mechanism 5, and the sliding platform 1 can drive the wire stripping mechanism 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com