Grain-oriented electrical steel sheet and method for producing same

A technology of grain-oriented electrical steel sheet and manufacturing method, which is applied in the direction of metal rolling and process efficiency improvement, etc., can solve the problems of hot-rolled sheet precipitation and uneven microstructure, magnetic attenuation, and aggravation of magnetic deviation of grain-oriented electrical steel sheet, etc. The effect of solving the unevenness of precipitates and microstructure, reducing thermal deviation, and improving magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] The steel composition is vacuum smelted to make a steel ingot, and the steel composition contains 2.8% Si, 0.09% Mn, 0.026% Al, 0.003% N, 0.004% S, 0.02% Sb, 0.05% Sn, 0.03% P, 0.03% Cr, and C varying in content as shown in Table 1, the remaining components include the balance of Fe and other unavoidable impurities, and then heated to a temperature of 1250°C , and then hot rolled to a thickness of 3.0mm, and then pickled and coiled. Then, without heat treatment, one-time cold rolling to a thickness of 0.30 mmt is performed on the cold-rolled sheet at a temperature of 860 °C and in a humid hydrogen, nitrogen and ammonia mixed gas atmosphere. The chemical annealing heat treatment was carried out to achieve a carbon content of 30 ppm and a nitrogen content of 190 ppm. Next, the steel sheet is coated with an annealing separator MgO and then subjected to final annealing heat treatment. The final annealing heat treatment is heated to 1200°C in a mixed gas atmosphere of 25 vo...

Embodiment 2

[0116]The steel component is vacuum smelted to make a steel ingot, and the steel component contains 0.09% Mn, 0.027% Al, 0.004% S, 0.02% Sb, 0.07% Sn, 0.03% P, 0.04% Cr, and Si, C, and N whose contents were changed as shown in Table 2, and the remaining components contained the remainder of Fe and other unavoidable impurities, and then heated to a temperature of 1150°C, and then hot rolled to a thickness of is 2.3mm. Then, pickling treatment is carried out, and without heat treatment, cold rolling is performed to a thickness of 0.23mmt once, and the cold-rolled sheet is subjected to a temperature of 850 ° C and a humid hydrogen, nitrogen and ammonia mixed gas environment. Simultaneously, a decarburization nitriding annealing heat treatment was performed so that the carbon content reached 30 ppm and the nitrogen content reached 170 ppm. Next, the steel sheet is coated with an annealing separator MgO and then subjected to final annealing heat treatment. The final annealing heat...

Embodiment 3

[0123] The embodiment is the same as the invention material 11, and the case where the annealing of the hot-rolled sheet after the hot-rolling is omitted or performed is compared.

[0124] [table 3]

[0125]

[0126] As shown in Table 3, it was confirmed that even if the annealing of the hot-rolled sheet was omitted, the magnetic properties were expressed corresponding to the case where the annealing of the hot-rolled sheet was performed.

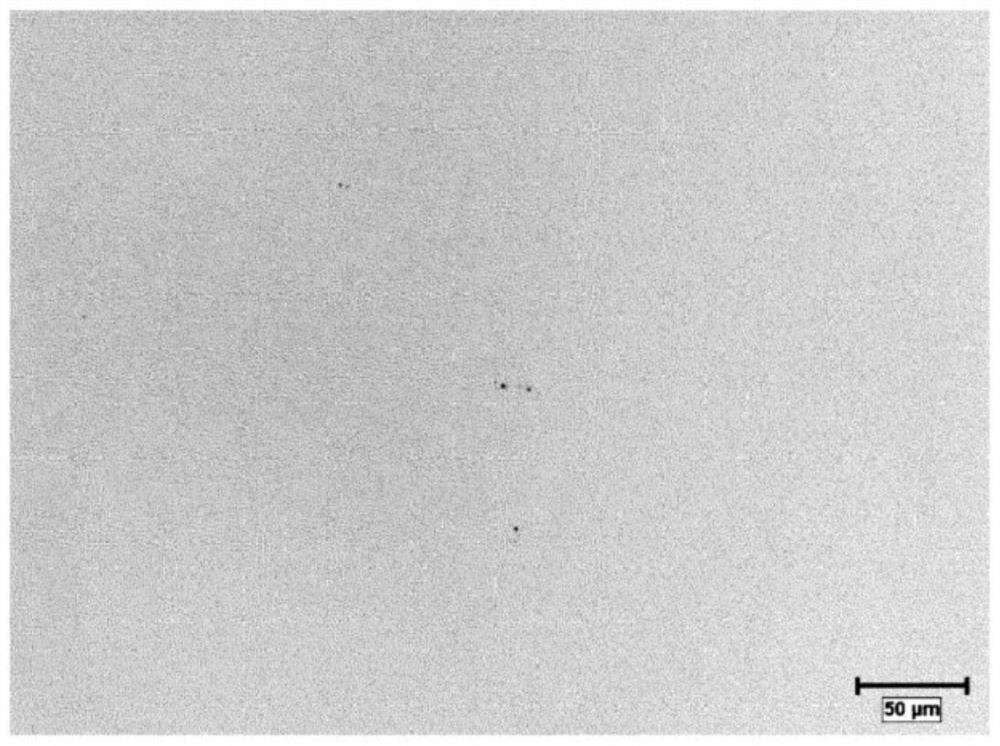

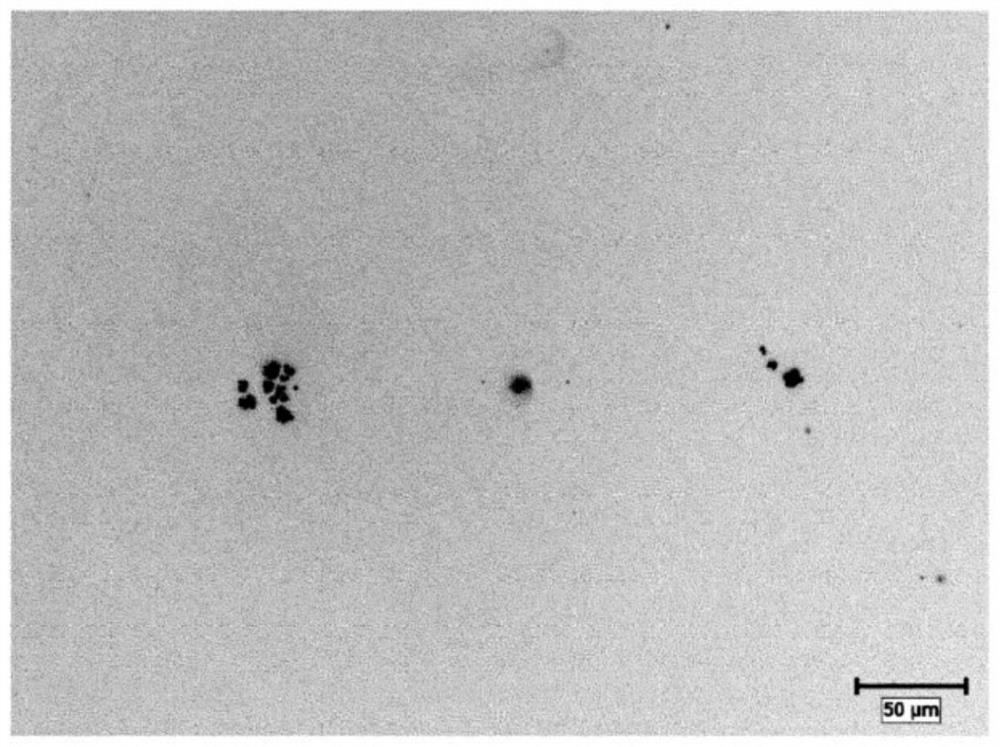

[0127] like image 3 and Figure 4 As shown, it was confirmed that the secondary recrystallization occurred completely in the inventive material 11 and the comparative material 23. In particular, in the case of the invention material 11, it was confirmed that secondary recrystallization occurred completely even if the hot-rolled sheet annealing was omitted.

[0128] On the other hand, if Figure 5 and Image 6 As shown, it was confirmed that secondary recrystallization did not occur completely in Comparative Material 11 and Comparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap