Lifting adjusting straw smashing device

A technology of straw crushing and lifting adjustment, which is applied to agricultural machinery and implements, excavating harvesters, and agricultural gas emission reduction. It can solve the problems of increased stubble height, low operating efficiency, and unclean straw crushing, and avoids shaking. , Reduce the effect of wear and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

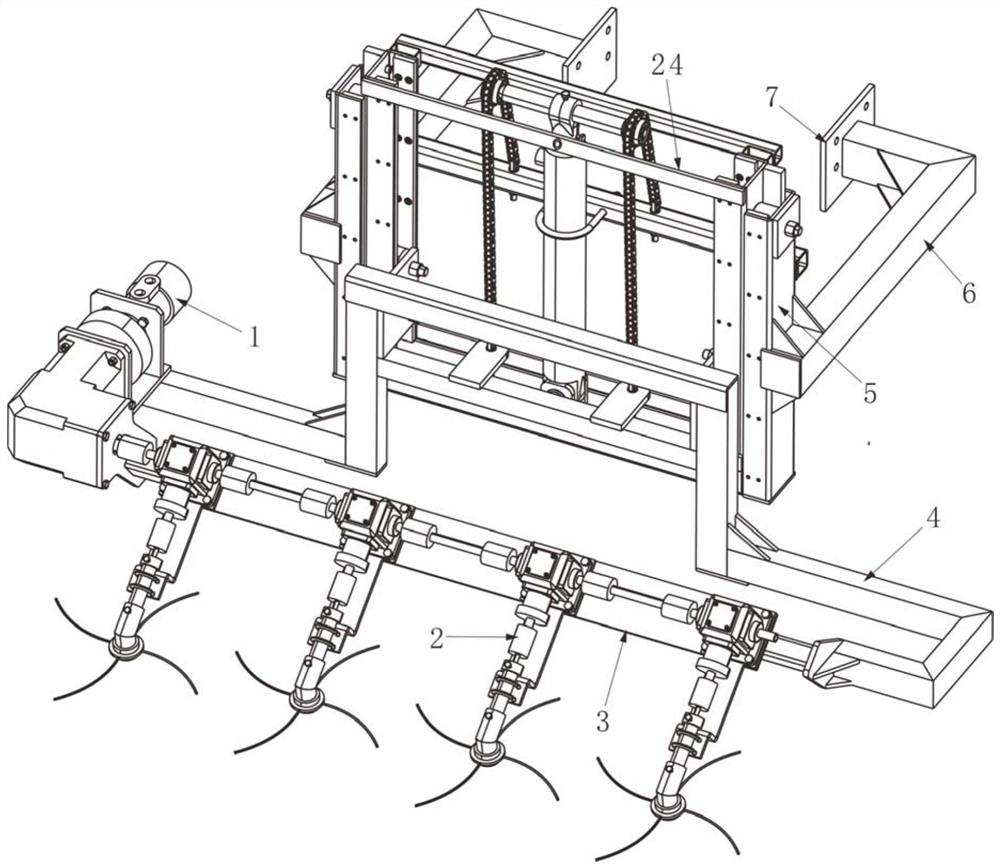

[0027] like figure 1 As shown in the figure, a lifting and adjusting straw crushing device includes a lifting frame 4, on which a plurality of straw crushing devices 2 are evenly arranged side by side, the lifting frame 4 is arranged on the first-level lifting mechanism, and the first-level lifting mechanism is connected to the second-level lifting mechanism. The stage lifting mechanism 5 is movably connected, and a driving mechanism for adjusting the height of the lifting frame is arranged between the second stage lifting mechanism 5 and the lifting frame 4 . A plurality of straw pulverizing devices 2 are connected by transmission, and one straw pulverizing device 2 is drivingly connected with a hydraulic motor 1. A hydraulic motor 1 drives several straw pulverizing devices 2 to rotate at the same time. The lifting frame 4 is provided with a plurality of straw pulverizing devices 2. Mounting plate 3.

[0028] This scheme is installed on a tractor, and the tractor drives the ...

Embodiment 2

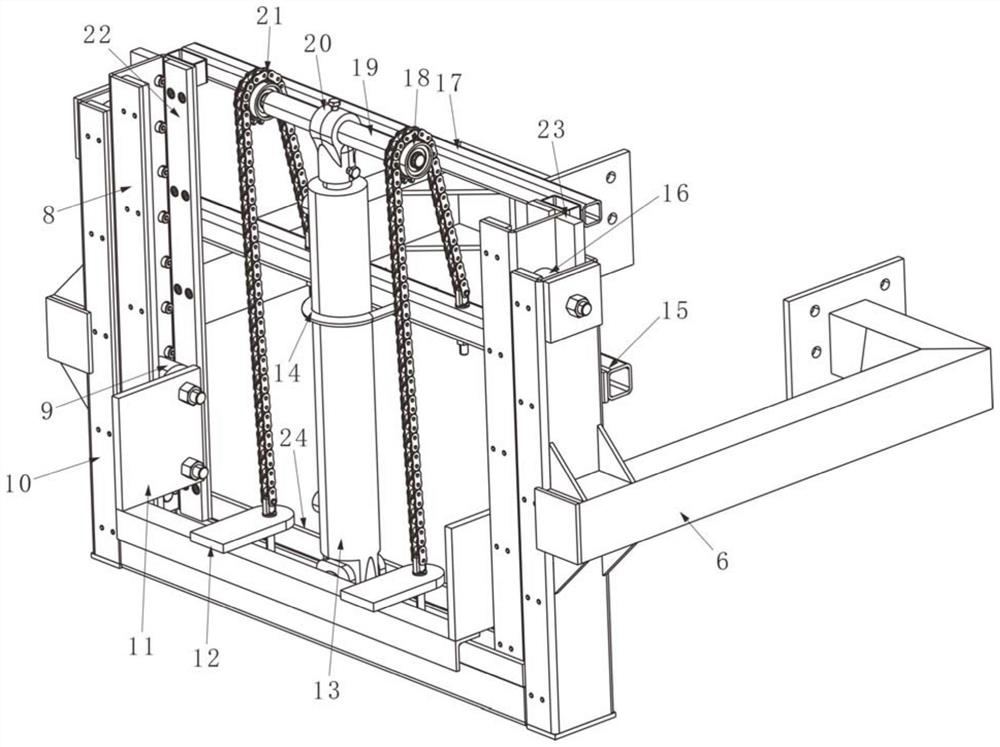

[0030] like figure 1 and figure 2As shown in the figure, a lifting and adjusting straw crushing device includes a lifting frame 4, on which a plurality of straw crushing devices 2 are evenly arranged side by side, the lifting frame 4 is arranged on the first-level lifting mechanism, and the first-level lifting mechanism is connected to the second-level lifting mechanism. The stage lifting mechanism 5 is movably connected, and the bottom of the second stage lifting mechanism 5 is provided with a driving mechanism for driving the first stage lifting mechanism and the second stage lifting mechanism 5 to ascend and descend sequentially.

[0031] This scheme is installed on a tractor, and the tractor drives the straw crushing operation in the field. Several straw crushing devices 2 are reasonably arranged according to the crop planting width to ensure that all planting widths can be covered and the operation efficiency is improved. At the same time, during the crushing operation, ...

Embodiment 3

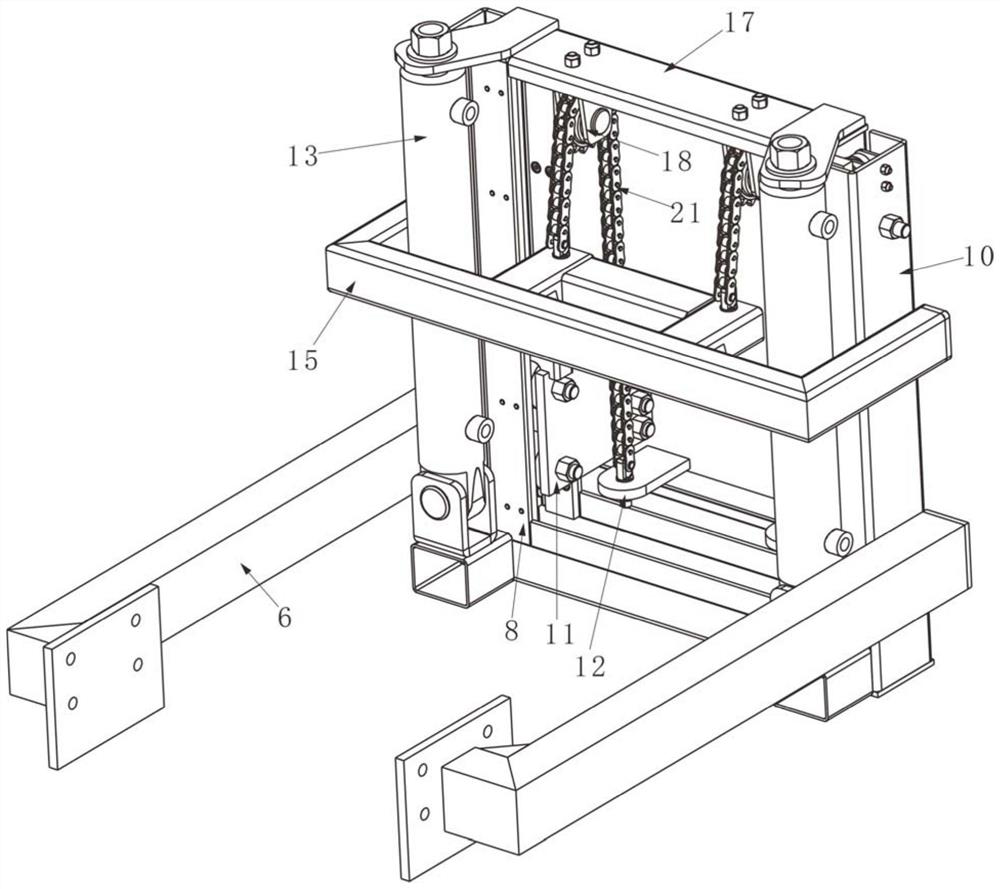

[0044] like Figure 1 to Figure 3 As shown in the figure, a lifting and adjusting straw crushing device includes a lifting frame 4, on which a plurality of straw crushing devices 2 are evenly arranged side by side, the lifting frame 4 is arranged on the first-level lifting mechanism, and the first-level lifting mechanism is connected to the second-level lifting mechanism. The stage lifting mechanism 5 is movably connected, and the bottom of the second stage lifting mechanism 5 is provided with a driving mechanism for driving the first stage lifting mechanism and the second stage lifting mechanism 5 to lift and lower simultaneously.

[0045] This scheme is installed on a tractor, and the tractor drives the straw crushing operation in the field. Several straw crushing devices 2 are reasonably arranged according to the crop planting width to ensure that all planting widths can be covered and the operation efficiency is improved. At the same time, during the crushing operation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com