Method for preparing Chinese yam beverage through step-by-step enzymolysis

A step-by-step enzymatic hydrolysis and yam technology, which is applied in food science and other fields, can solve the problems of slag feeling and viscous yam drink, and achieve the effect of smooth taste, increased sweetness, and precise control of the degree of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

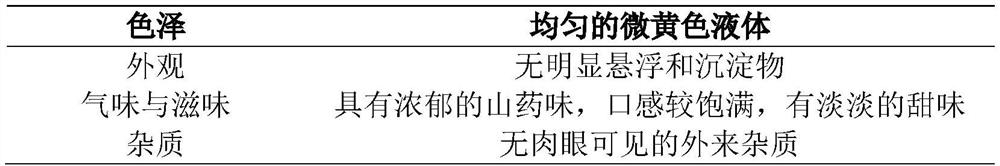

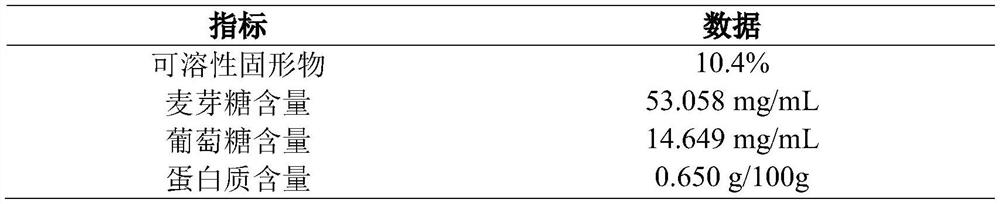

[0026] Embodiment 1, step-by-step enzymolysis to prepare yam enzymolysis beverage

[0027] 1. Yam enzymolysis drink

[0028] (1) Beating: Mix 0.2kg of yam powder with water in a mass ratio of 1:9, pour into a colloid mill (JMFB-140 split colloid mill, Hangzhou Huihe Machinery Equipment Co., Ltd.) 2880r / min circulating refining 10min to obtain yam pulp;

[0029] (2) Enzymatic hydrolysis in the first step: after heating the yam pulp prepared in step (1) to 70° C., add 0.2 mL of medium-temperature amylase, stir evenly, and keep warm for 5 minutes;

[0030] (3) The second step of enzymatic hydrolysis: after the first step of enzymatic hydrolysis is completed, the yam pulp is cooled to 60 ° C, 0.2 mL of maltose amylase is added to the yam pulp, and the reaction is incubated for 20 minutes after stirring;

[0031] (4) The third step of enzymatic hydrolysis: after the second step of enzymatic hydrolysis is completed, maintain at 60 °C, add 0.2 mL of saccharification enzyme to the y...

Embodiment 2

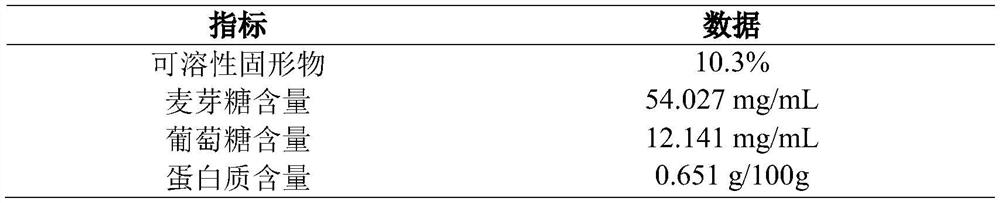

[0047] Embodiment 2, step-by-step enzymolysis to prepare yam enzymolysis beverage

[0048] (1) beating: 0.2kg of yam powder and water are mixed by mass ratio 1:9, poured into a colloid mill, and milled with the method of Example 1 to obtain yam pulp;

[0049] (2) Enzymatic hydrolysis in the first step: heating the yam pulp in step (1) to 70° C., adding 0.2 mL of medium-temperature amylase to the yam pulp, stirring evenly, and maintaining the reaction for 5 min;

[0050] (3) The second step of enzymatic hydrolysis: after the first step of enzymatic hydrolysis is completed, the yam pulp is cooled to 60 ° C, 0.2 mL of maltose amylase is added to the slurry, and the reaction is incubated for 30 min after stirring;

[0051] (4) Enzymatic hydrolysis in the third step: after the enzymatic hydrolysis in the second step is completed, maintain the yam slurry at 60°C, add 0.2 mL of saccharifying enzyme to the slurry, stir evenly and keep warm for 30 min;

[0052] (5) inactivating enzyme: ...

Embodiment 3

[0060] Embodiment 3, step-by-step enzymolysis to prepare yam beverage

[0061] (1) beating: 0.2kg of yam powder and water are mixed by mass ratio 1:9, poured into a colloid mill, and the yam pulp is subjected to grinding by the method of embodiment 1;

[0062] (2) Enzymatic hydrolysis in the first step: heating the yam slurry in step (1) to 70° C., adding 0.2 mL of medium-temperature amylase to the slurry, stirring evenly, and maintaining the reaction for 5 min;

[0063] (3) Enzymatic hydrolysis in the second step: after the enzymatic hydrolysis in the first step is completed, the yam slurry is cooled to 60°C, 0.2 mL of maltose amylase is added to the slurry, and the reaction is incubated for 40 min after stirring;

[0064] (4) Enzymatic hydrolysis in the third step: after the enzymatic hydrolysis in the second step is completed, the yam pulp is maintained at 60°C, 0.2 mL of saccharification enzyme is added to the pulp, and the mixture is stirred for 20 minutes;

[0065] (5) ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap