Intelligent stirring equipment based on internet-of-things control

A kind of mixing equipment, intelligent technology, applied in the program control of sequence/logic controller, mixer accessories, comprehensive factory control, etc., can solve the problems of reduced production efficiency, equipment failure, insufficient perception ability, etc., to ensure reliability , Improve remote monitoring and control capabilities, and improve the effect of network capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

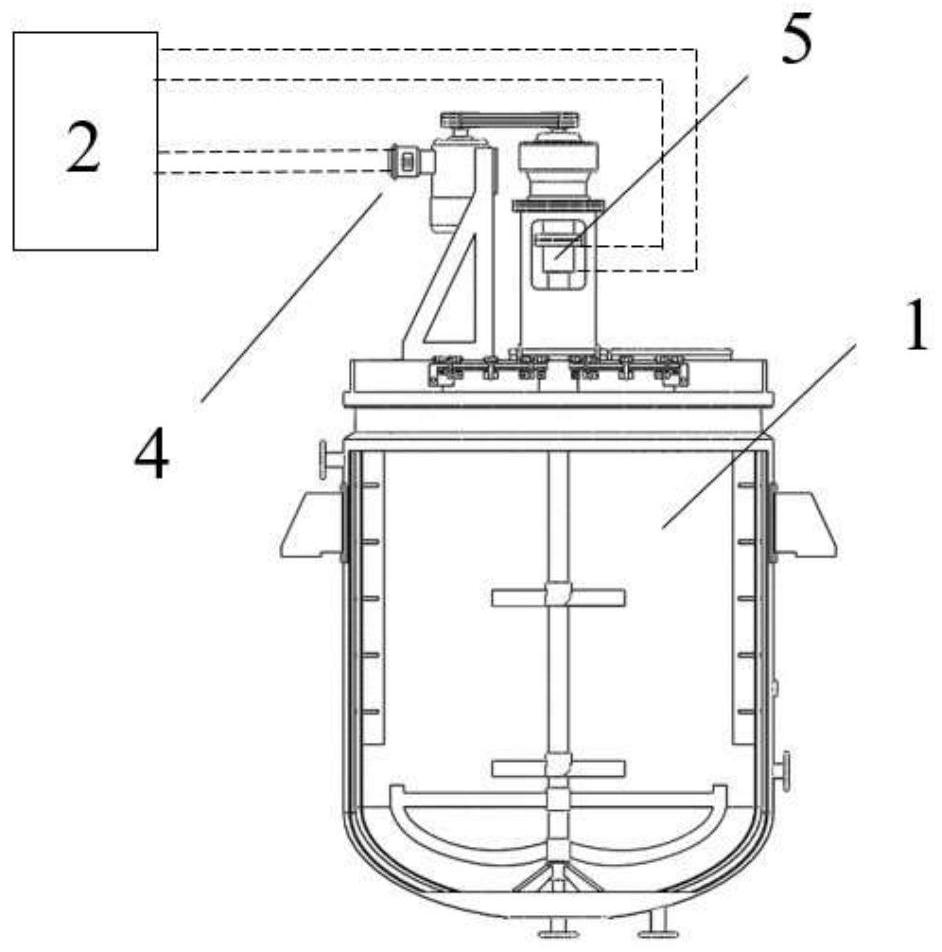

[0053] Please refer to the attached image,

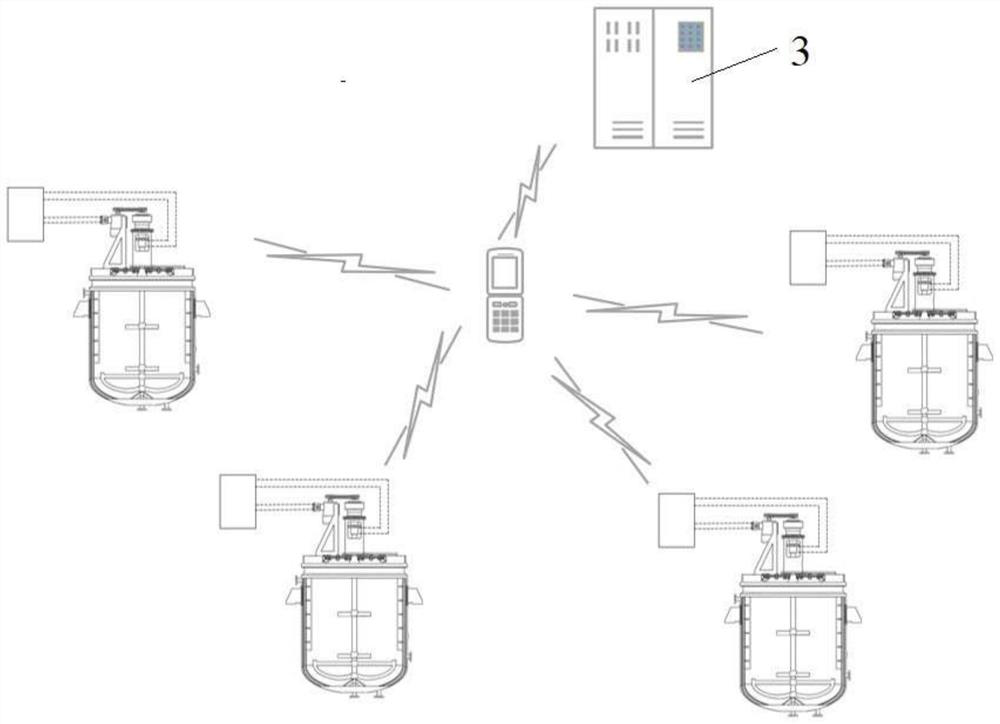

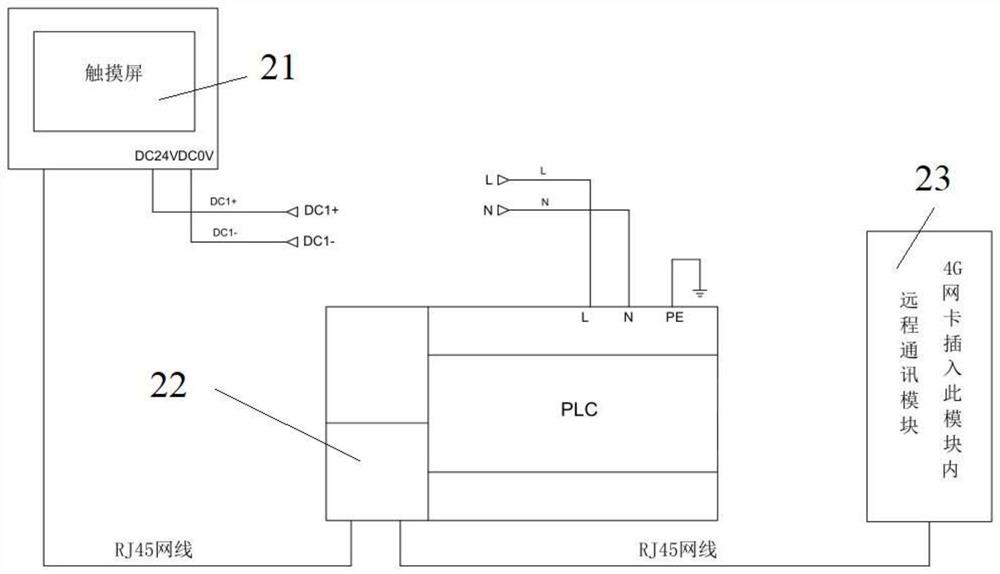

[0054] An intelligent stirring device based on IoT control, comprising a stirring device 1 and a control system 2, the control module includes a touch screen 21, a PLC module 22 and a remote communication module 23, characterized in that: the remote communication module 23 includes a network card socket , the network card socket is used to connect the 4G network card, and the 4G network card is used for remote communication with the user's mobile phone. The user logs in the background of the remote communication module on the mobile phone, and displays the status of the device to be displayed on the touch screen. The parameters of the remote communication module are compiled on the background of the remote communication module. After the preparation is completed, the device can be controlled and the relevant operating status of the device can be checked on the mobile phone. The control system 2 also communicates with the Internet of...

Embodiment 2

[0066] A method for troubleshooting an intelligent stirring device based on IoT control, characterized in that the method is based on the intelligent stirring device, and the method for troubleshooting includes the following steps:

[0067] S1. Preparation steps: Engineers use professional programming software to compile the logic control program of the mixing equipment in the computer, and then download it to the PLC module; then, use the professional touch screen control screen and related parameters in the computer to compile and download it. to the touch screen. Then, connect the touch screen and the PLC with a network cable; carry out a communication check on each intelligent stirring device, and complete the remote communication connection with the user's mobile phone and the Internet of Things server 3;

[0068] S2. Pre-experimental steps: load a predetermined amount of material, start stirring, record the relationship curve between stirring time and torque, when the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com