Rail system for spraying automobile frameless sealing strip

A technology of sealing strips and rails, applied in the field of rails, can solve the problems of no production equipment, inability to produce rapidly and continuously, and slow production speed, and achieve the effects of stable operation, improved spraying quality and efficiency, and stable driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

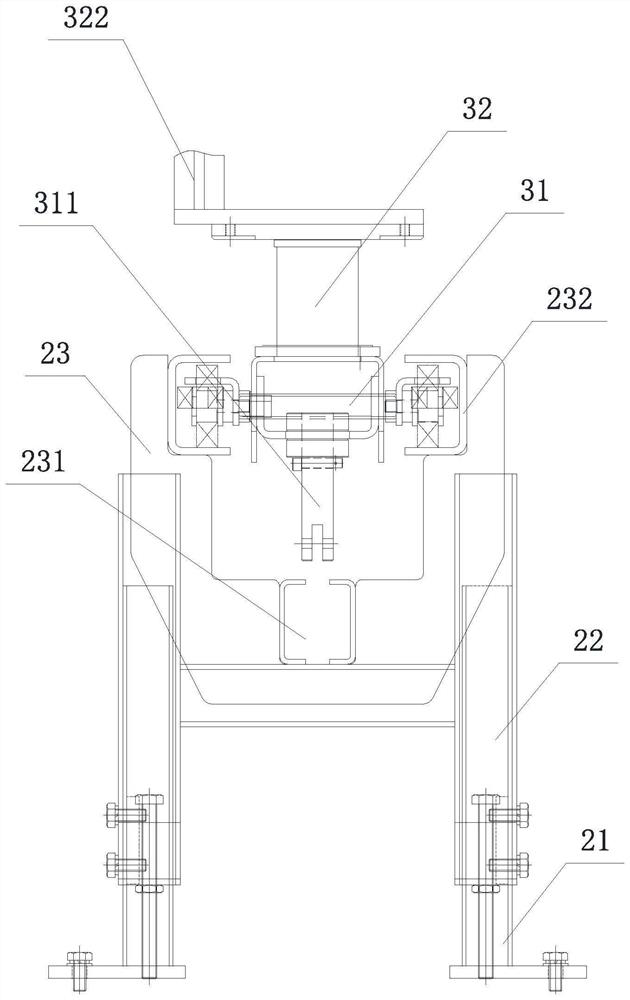

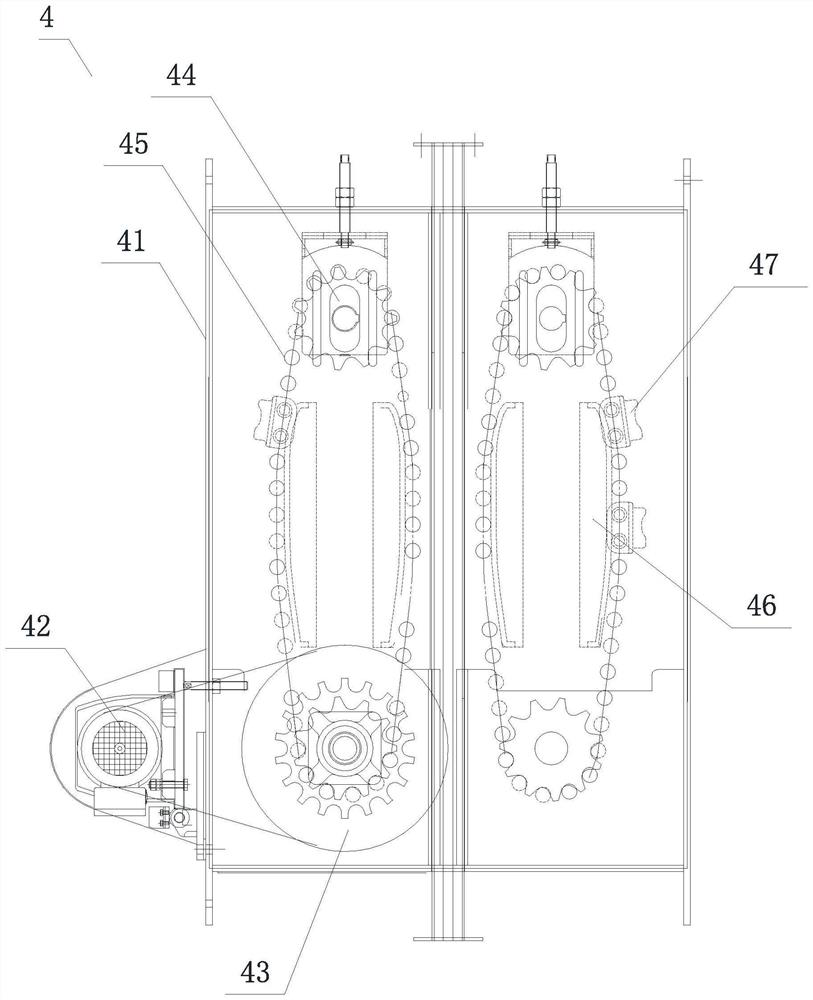

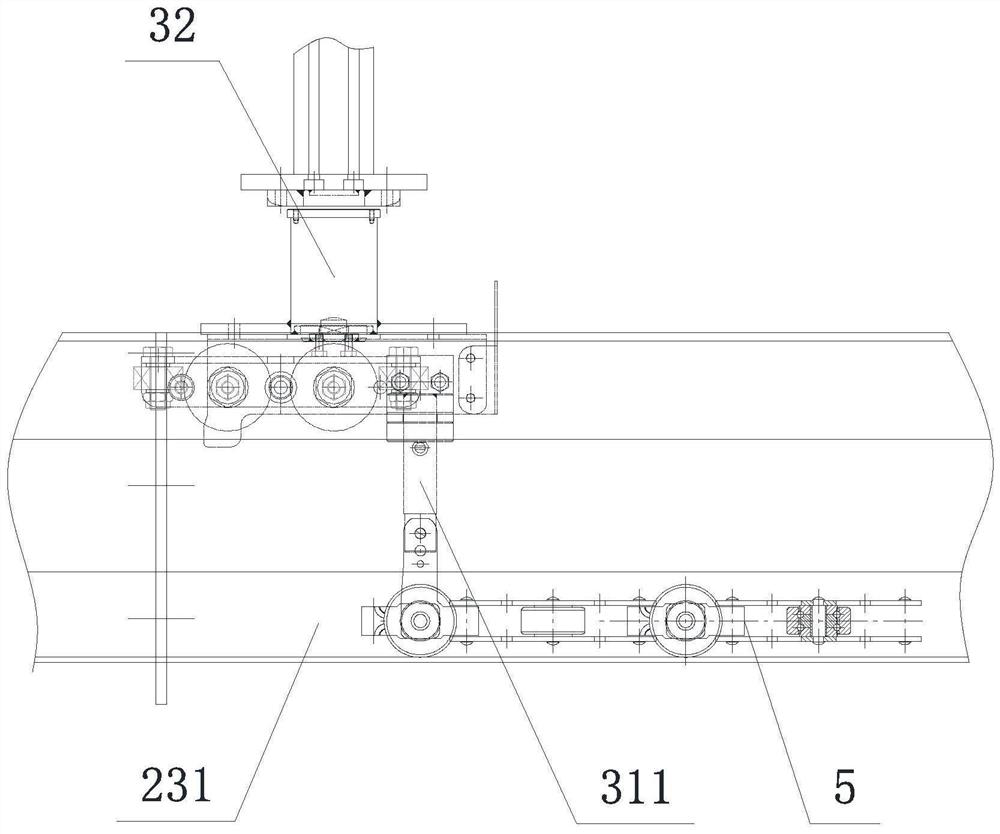

[0025] see Figure 1-Figure 5 The invention provides a track system for spraying frameless sealing strips of automobiles, which includes a fixed seat fixed on the workshop floor, a track installed on the fixed seat and a driving mechanism, the track is connected end to end and forms a closed loop, which can realize circulation For conveying, a drive chain 5 is arranged on the track, and hangers 32 are equidistantly arranged on the drive chain 5, and the distance between two adjacent hangers is greater than or equal to 1m and less than or equal to 2m; refer to figure 1 , the track includes a track body 23, and a mounting groove with an open upper end is formed in the track body 23, that is, the cross section of the track is a U-shaped structure with an upward opening, and an upper chute 232 and a lower chute 231 are arranged in the mounting groove, T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap