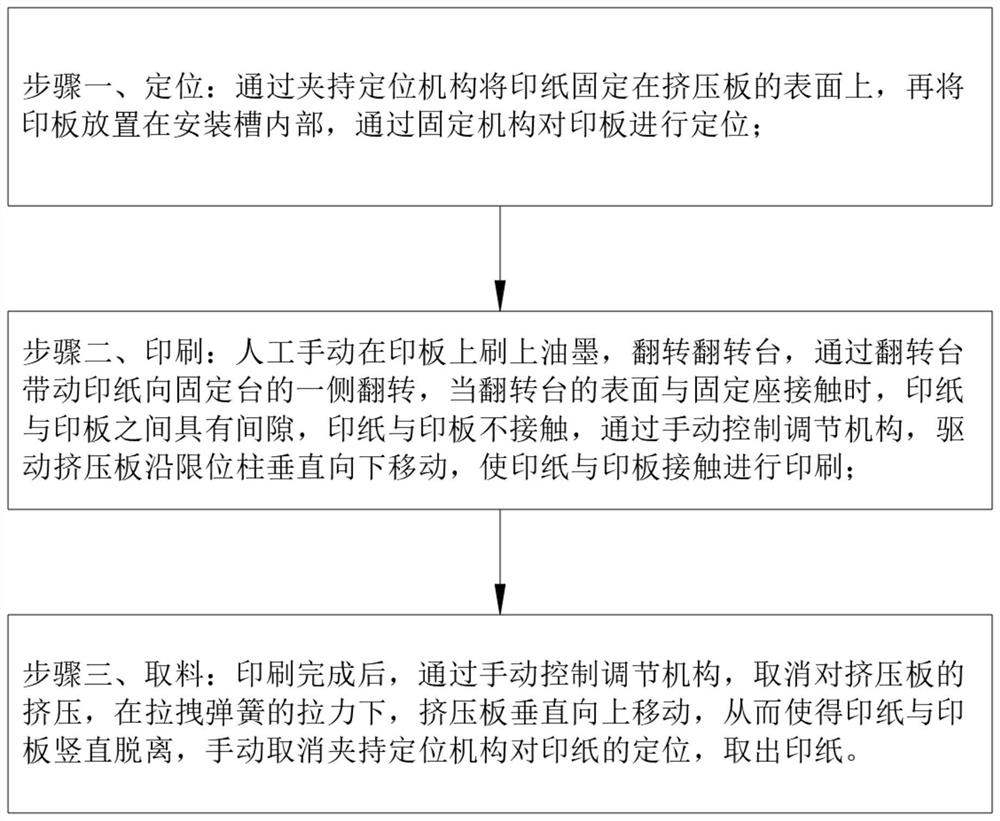

Print registering device and using method thereof

A technology of printmaking and turning table, which is applied in printing, printing machine, flatbed printing machine, etc., to achieve the effect of uniform and clear lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The preferred embodiments described below are given by way of example only, and other obvious modifications will occur to those skilled in the art.

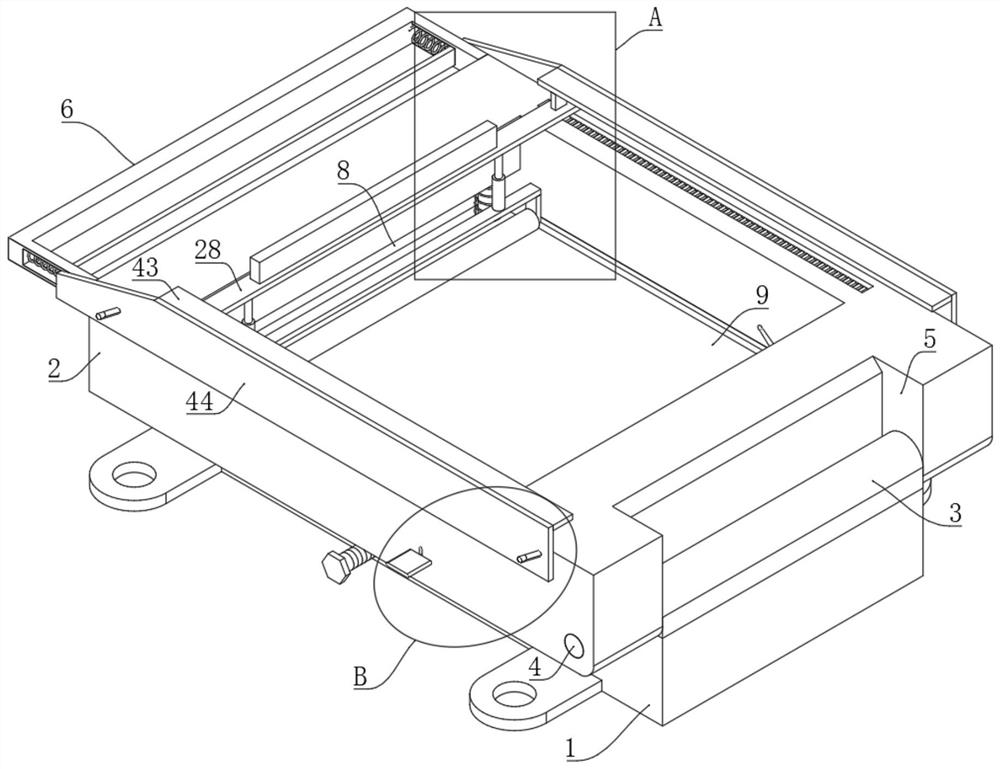

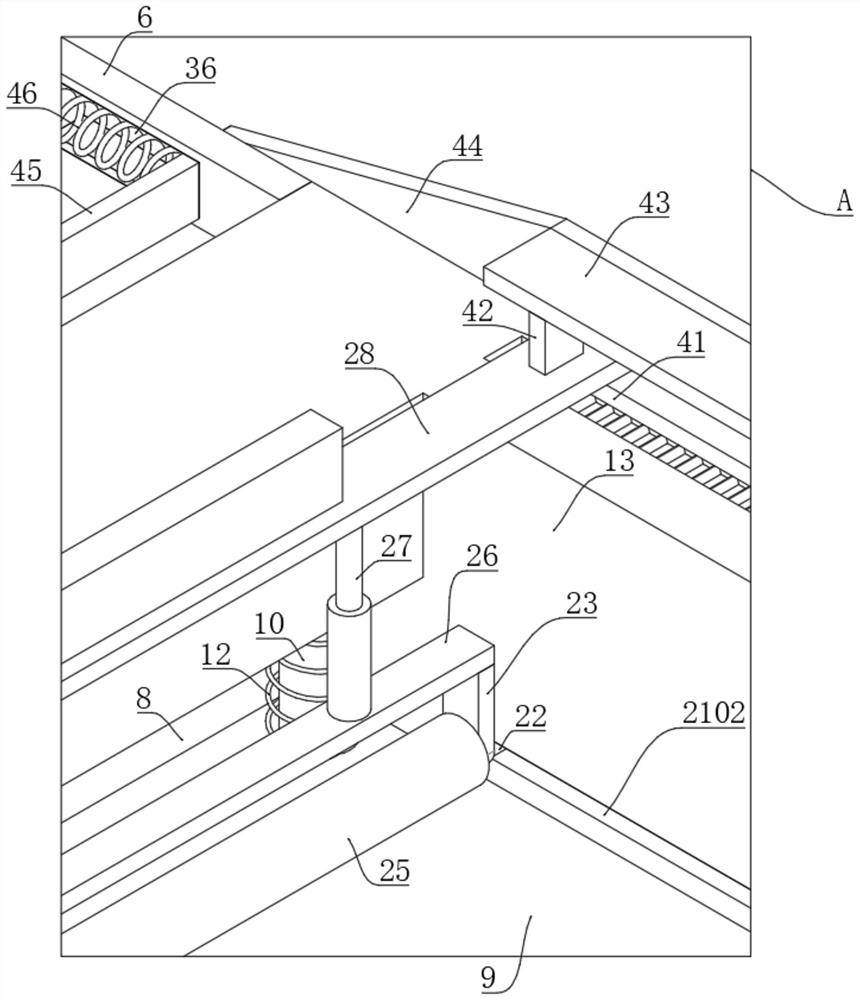

[0038] like Figure 2 to Figure 12A type of print matching device shown includes a fixed seat 1 and a turning table 2, a fixing bar 3 is fixed on the fixing seat 1, a rotating shaft 4 is fixed on the side wall of the fixing bar 3, and a side wall of the turning table 2 is opened. There is a vacant slot 5, the fixing strip 3 is inserted in the vacant slot 5, the rotating shaft 4 is rotatably connected to the side wall of the vacant slot 5, and the handle 6 is fixed on the side of the turning table 2 away from the fixing seat 1; the fixing seat The top surface of 1 is provided with a mounting slot 7, and the interior of the mounting slot 7 is provided with a fixing mechanism, which is used to fix the prin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap