Pay-off pulley device

A pay-off pulley and cable technology, applied in transportation and packaging, thin material handling, cable laying equipment, etc., can solve the problems of low work efficiency, increased workload, inability to adjust, etc., to achieve flexible use, avoid pairing work, Protection from wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

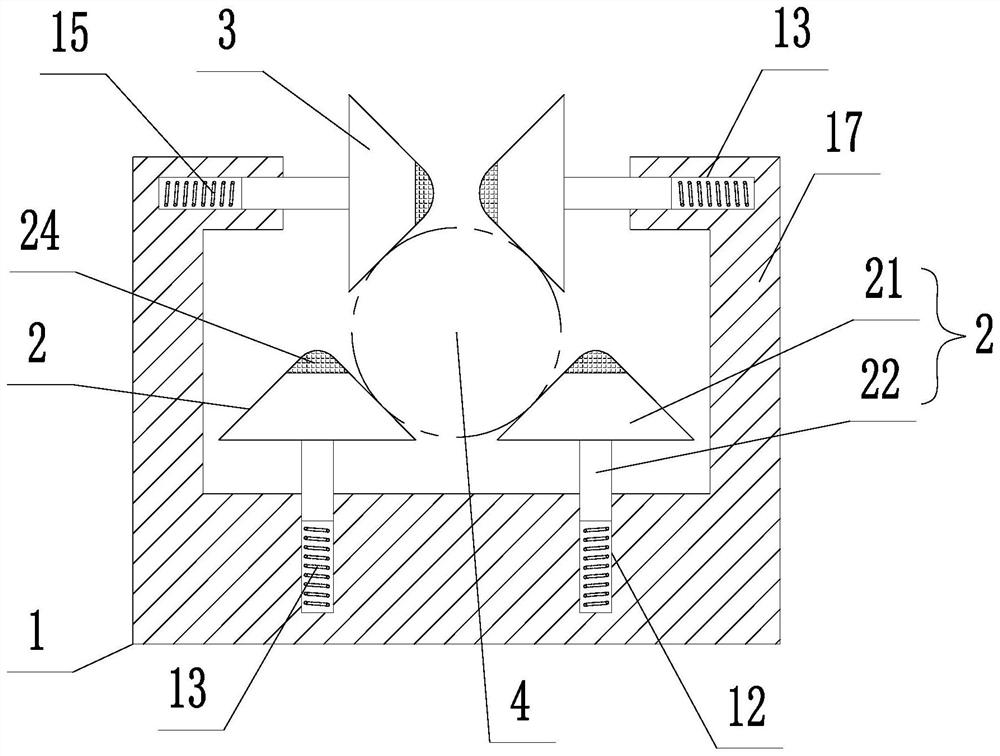

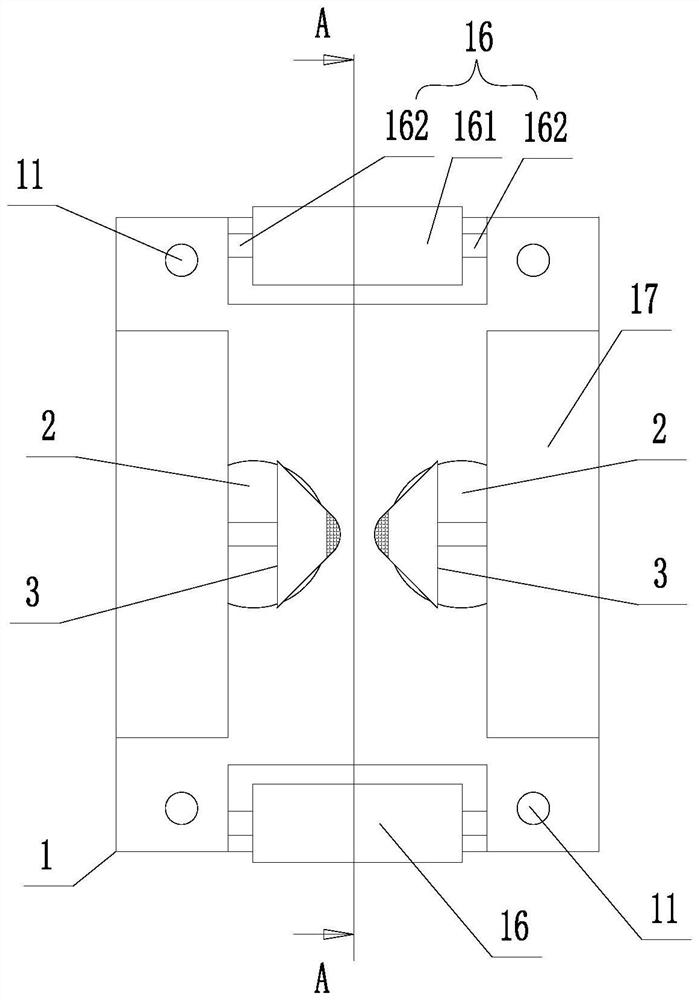

[0027] Example 1: see Figure 1-4 ;

[0028] The present invention provides the following technical solutions:

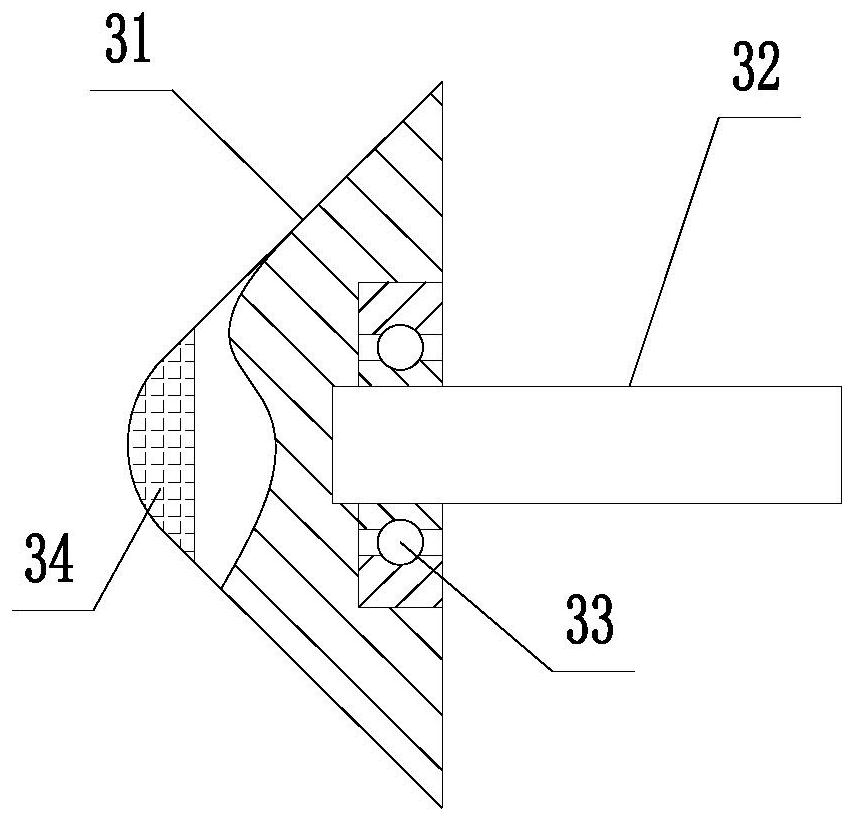

[0029] A pay-off pulley device, including a base 1, the upper surface of the base 1 is provided with two left-right symmetrical vertical plate parts 17 and a plurality of through holes 11 for mounting the base 1 on a support, so that the bolts can pass through the base 1. It is installed on the cross arm through the through hole 11; the upper surface of the base 1 is also provided with a pair of vertical first sockets 12, and the upper end of the vertical plate portion 17 is provided with a horizontal second socket 13, so The first insertion hole 12 and the second insertion hole 13 are respectively provided with a first spring 14 and a second spring 15; the front and rear edges of the upper surface of the base 1 are provided with rotatable roller shafts 16. The shaft 16 is used to reduce the wear when the cable passes through the front and rear edges of the upper ...

Embodiment 2

[0039] Example 2: see Figure 1-5 ;

[0040] A pay-off pulley device is different from Embodiment 1 in that the base 1 has four first sockets 12, and each of the first sockets 12 is plugged with one of the first rotating cone heads 2 ;

[0041] The four first jacks 12 are divided into two groups, and each group of two first jacks 12 is located on the left and right sides of the cable respectively; the two groups of first jacks 12 are along the axial direction of the cable. Arrangement; the second rotating cone head 3 is located in the middle of the two groups of first sockets 12; such as Figure 5 shown.

[0042] Correspondingly, there are also four first rotating cone heads 2 . Compared with Embodiment 1, this embodiment has the advantages of Embodiment 1. The number of the first rotating cone heads 2 in the lower part is more, the lifting capacity of the cable is stronger, and it can bear a larger traction force, so that the When pulling the cable through the device, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com