Automatic rapeseed oil frying equipment

A technique for frying rapeseed oil and seeds, which is applied in chemical instruments and methods, fat oil/fat production, and recovery of fatty substances, etc. It can solve the problem that the amount of water is difficult to effectively control, etc., to promote fast ripening and increase steam Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

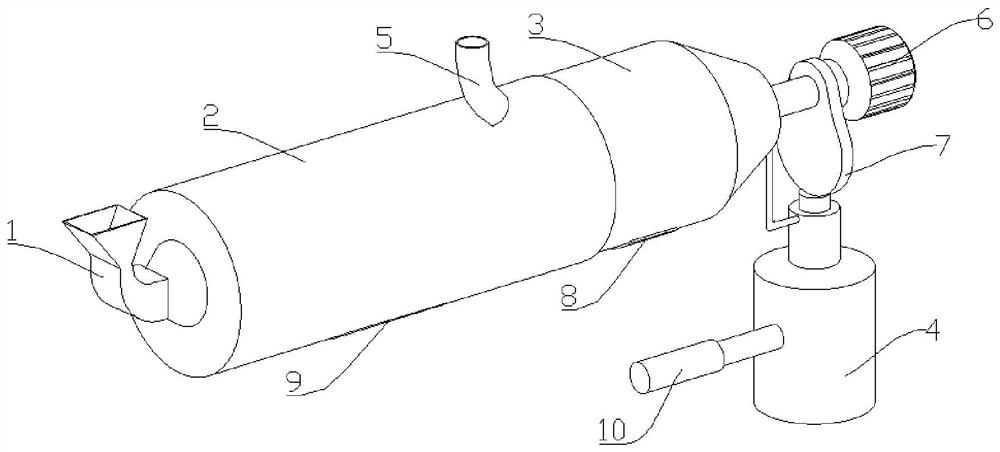

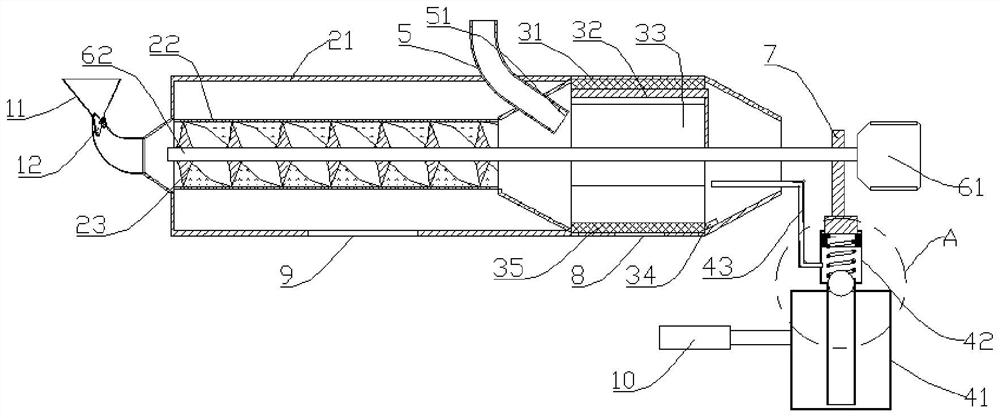

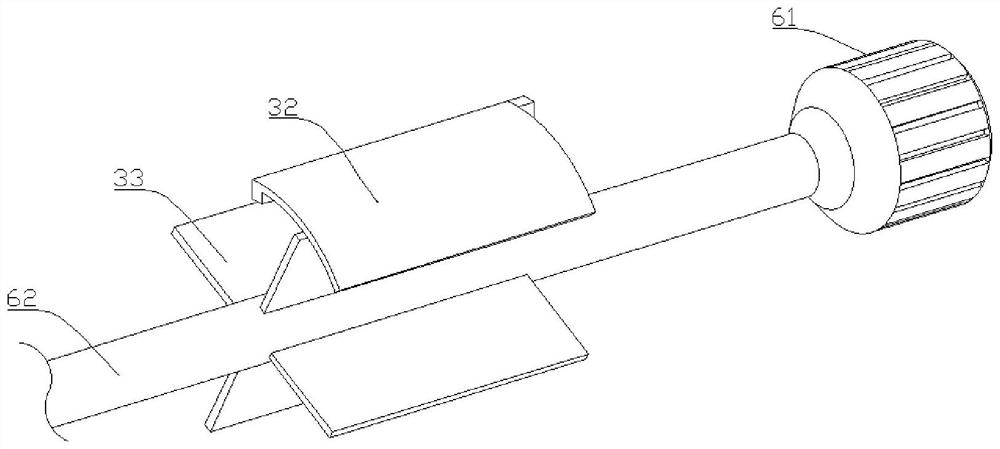

[0035] Embodiment, a kind of rapeseed oil automatic frying equipment, combined with Figure 1-7It can be seen that, including the feeding part 1, the screening part 2 communicated with the feeding part 1, the stirring part 3 and the driving assembly 6 communicated with the sieving part 2, the feeding part 1 is provided with a grinding wheel for rapeseed embryo rolling. The pressing component 12 and the driving component 6 include a driving motor 61 and a rotating shaft 62. The rotating shaft 62 passes through the stirring part 3 and the sieving part 2 in turn, and a cam 7 is fixedly arranged at one end close to the driving motor 61. The bottom side of the cam 7 is provided with a sprinkler component 4. The sprinkler assembly 4 includes a water tank 41, a pressing pump arranged on the top side of the water tank 41, and a water pipe 43 extending into the inside of the stir-frying portion 3. The cam 7 is located vertically above the pressing pump and forms a pressing fit with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com