Blast furnace ironmaking process monitoring method based on Local-DBKSSA

A technology of process monitoring and blast furnace ironmaking, applied in the direction of electrical program control, comprehensive factory control, manufacturing computing system, etc., can solve the problems of loss of performance, lack of multi-view complex dynamics, nonlinearity, burial, etc., and achieve high fault monitoring rate , Improving the monitoring ability and the effect of low false detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

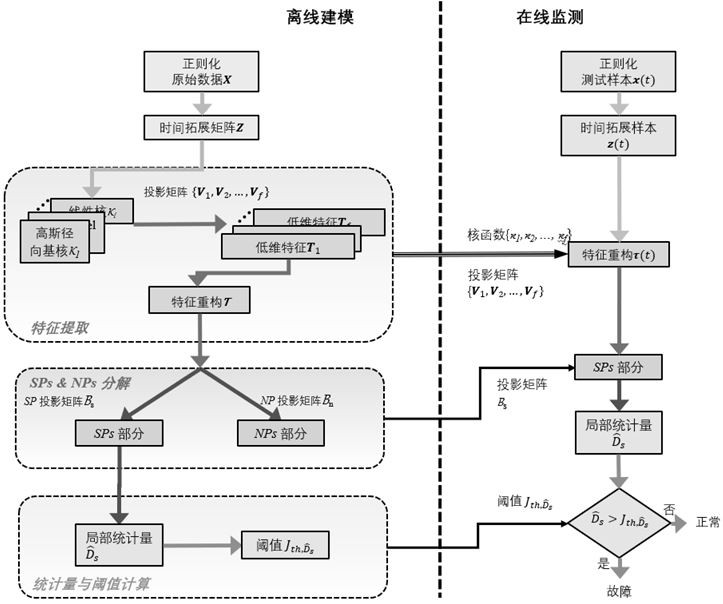

[0055] In order to describe the technical solutions of the present invention more clearly and completely, the present invention will be further elaborated below with reference to the accompanying drawings and embodiments.

[0056] like figure 1 As shown, a modeling method based on local dynamic wide-kernel steady-state subspace analysis (Local-DBKSSA) of the present invention includes the following steps:

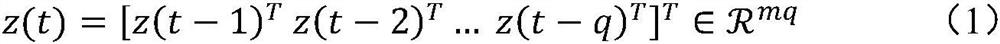

[0057] (1) For offline modeling, each sensor (flow sensor, temperature sensor, concentration sensor, etc.) needs to be installed at each position in the process, and the corresponding data is stored in the database. Then, based on the data collected in the database, the process data during normal operation, where the m-dimensional measurement vector at the t-th time can be expressed as Subsequently, the time lag vector can be constructed as follows,

[0058]

[0059] Here the parameter q represents the number of time lags, and T is the transpose symbol. After colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com