Variable-working-condition rolling bearing sectional type fault diagnosis method and system

A fault diagnosis system and rolling bearing technology, applied in mechanical bearing testing, comprehensive factory control, character and pattern recognition, etc., can solve problems such as scarcity of fault data, inaccurate fault classification, and improve training efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

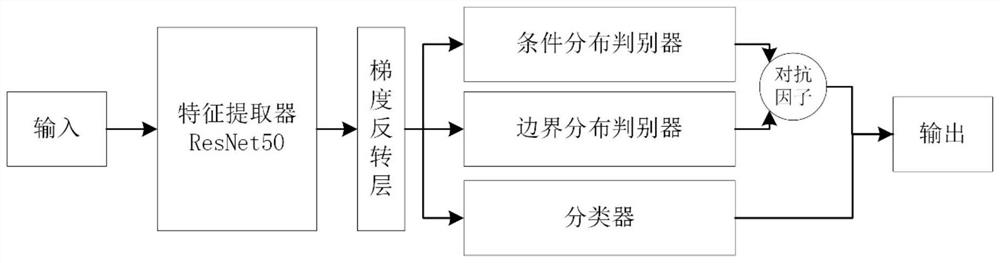

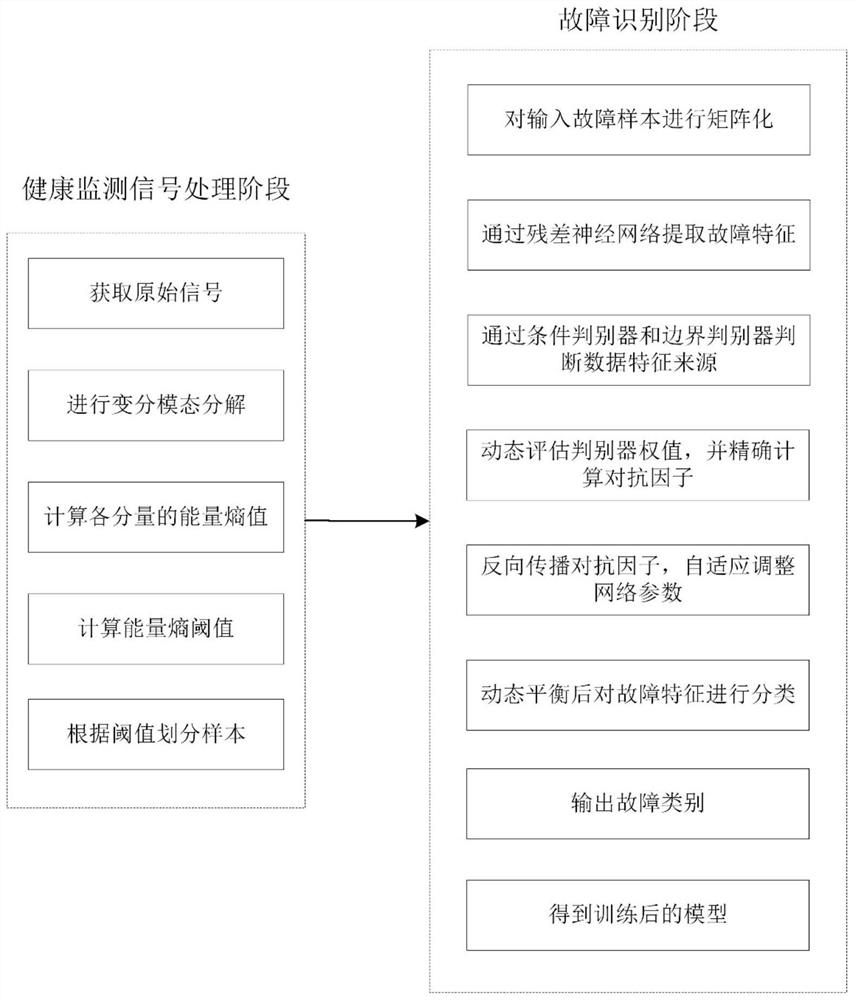

[0150] like figure 1 As shown, this embodiment provides a method for segmented fault diagnosis of a rolling bearing with variable working conditions based on a dynamic confrontation transfer learning network, the method includes a bearing working state intelligent monitoring phase and a fault identification phase;

[0151] In order to better reflect the universality of the present invention, relatively ghostwriting rolling bearing data is selected. In this embodiment, the driving end rolling bearing data with a sampling frequency of 12 kHz is selected as the research object;

[0152] Table 1

[0153]

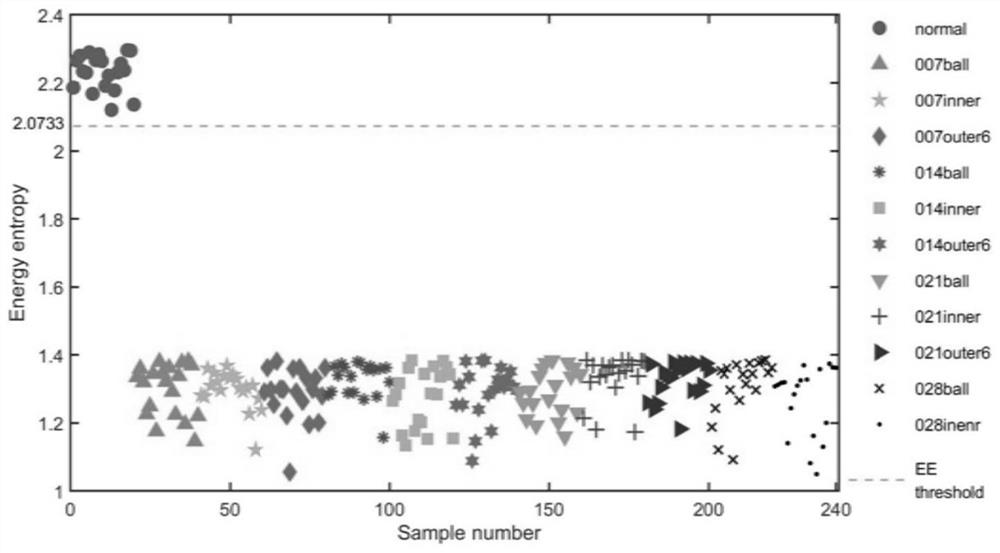

[0154]As shown in Table 1, there are a total of 11 faults and a set of normal data; different speeds correspond to different working conditions, 1797 / 1772 / 1750 / 1730r / min correspond to 0 / 1 / 2 / 3hp load conditions; hp means horsepower, is the unit for measuring the load; in this embodiment, different working conditions are used as the training set and the test set respectively. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap