Improved method for chromizing small parts

A kind of component, fragmented technology, applied in the field of diffusion coating applied to industrial parts, can solve the problems of ineffective, time-consuming, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

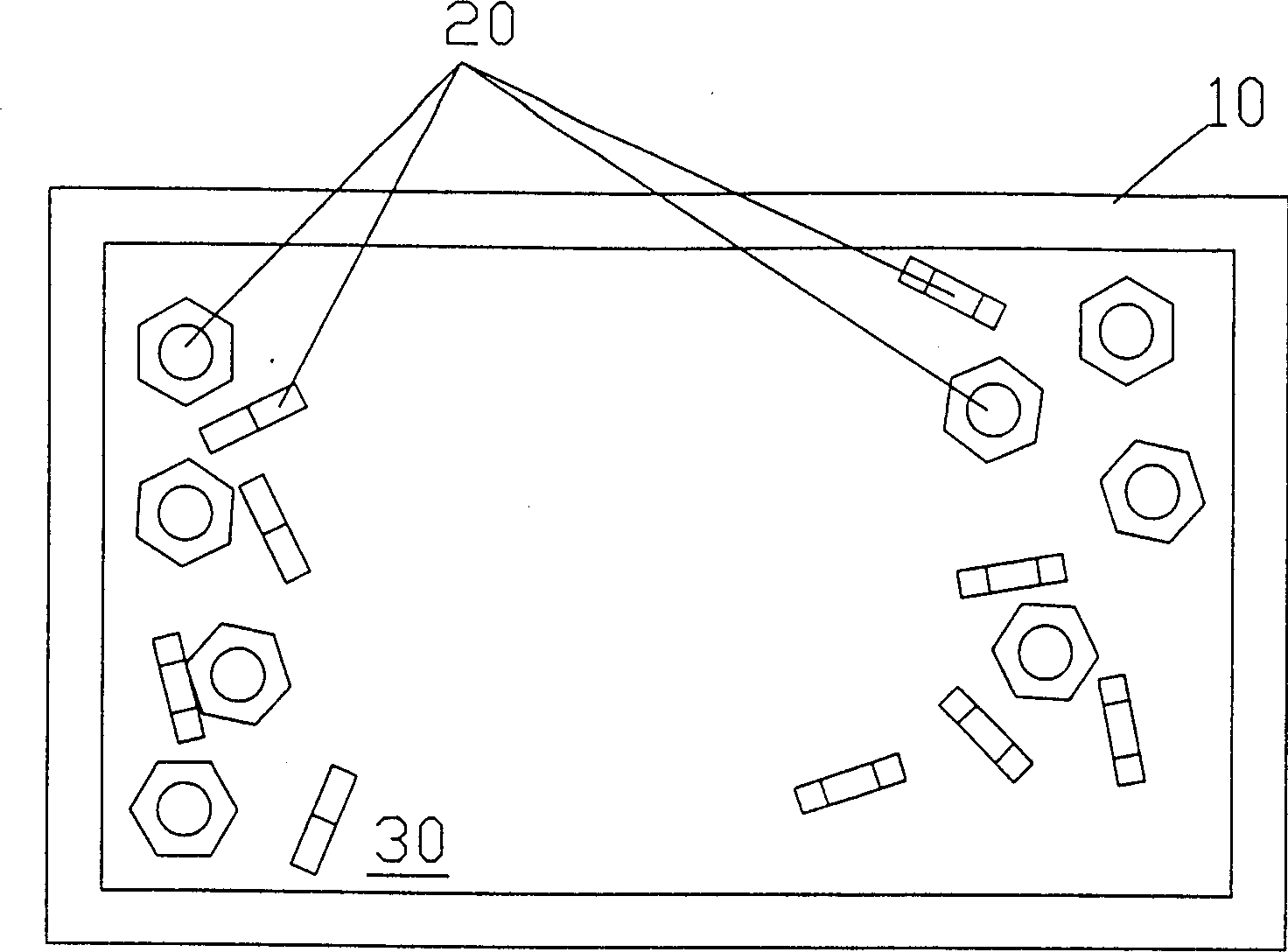

[0040]The method of the present invention is to diffuse and coat one layer of high-concentration chromium layer on industrial quantities of ferrous scattered small parts (such as but not limited to screws, nuts, washers, fasteners, fittings, couplings, bolts, etc. or similar parts) ways to improve.

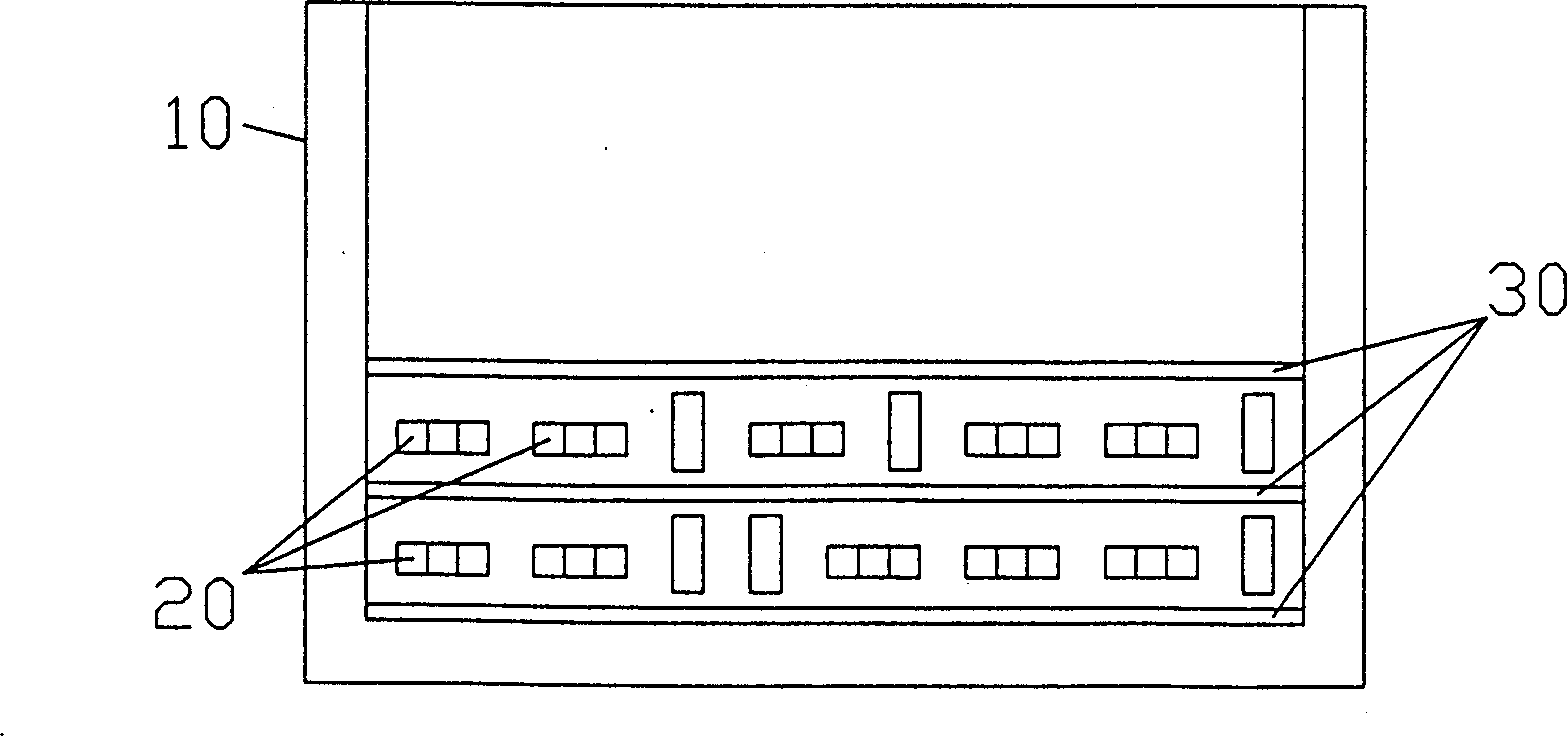

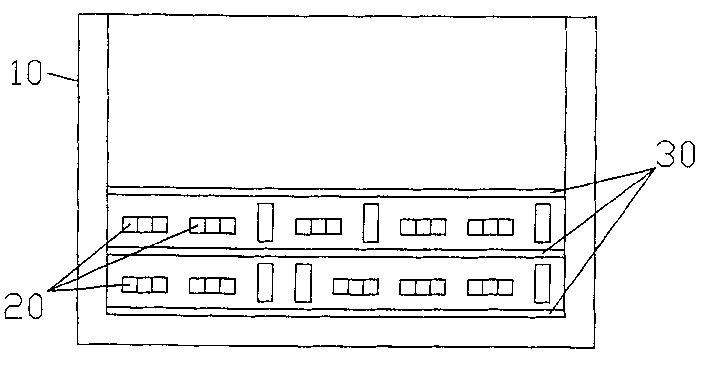

[0041] Referring to the accompanying drawings, first of all there needs to be a figure 1 with figure 2 Retort 10 is shown. A layer of refractory felt paper 30 is placed on the bottom of the retort 10. The refractory felt paper 30 may be of any type, such as FIBERFRAX from Unifrax Corporation Ceramic fiber or KAOXOOL of Thermal Ceramics Felt paper made of ceramic fibers. It can also be a thin layer of insulating batt.

[0042] Then, many small parts 20 (shown as an example with hexagonal nuts and straight pins among the figures) are placed on the felt paper 30, and these many irony parts and felt paper are regarded as one layer. Even though small parts may be in contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com