Process for preparing gamma-mercaptopropyl-trimethyloxysilane

A technology of mercaptopropyltrimethoxysilane and chloropropyltrimethoxysilane is applied in the field of synthesis of fine chemicals, can solve the problems of low yield, complicated operation and the like, and achieves high yield, good purity and product cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

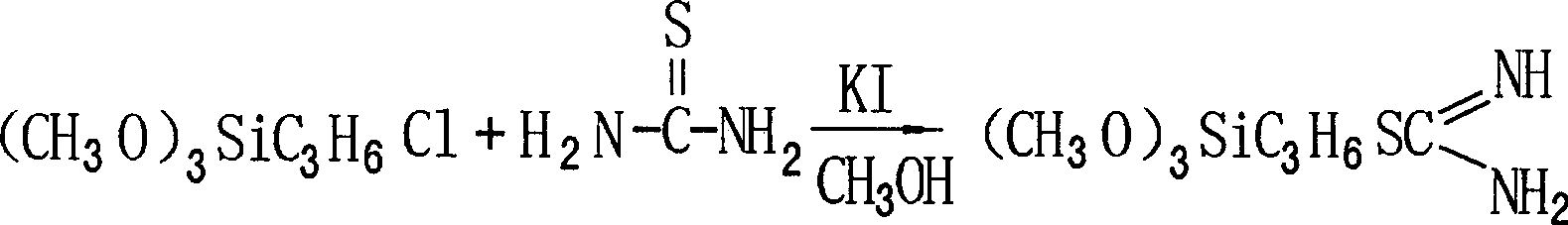

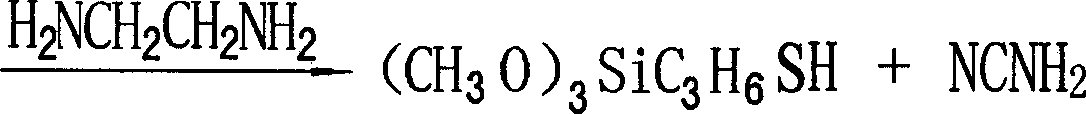

Method used

Image

Examples

Embodiment

[0013] Example: Dry thiourea and potassium iodide at 100-105°C for 4 hours, add 60g of γ-chloropropyltrimethoxysilane, 28g of dried thiourea, 32g of methanol, and 0.7 g, heat and stir, reflux at 69-73°C for 24 hours, cool down to 60°C, add 10g of ethylene glycol dropwise, stir at 70-73°C for 0.5 hours, change to a distillation device, distill off the solvent methanol, and then depressurize to 4132~4266Pa (31~32mmHg), the product collected at 140~150°C is γ-mercaptopropyltrimethoxysilane, the yield is 78%, and the product content is ≥98%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap