Seluofle spinning modulus compensator

A technology of sirofill spinning and compensating device, which is applied in the direction of spinning machine, yarn, textile and papermaking, etc., to achieve the effect of improving anti-"stripping" performance, high yarn strength and less hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

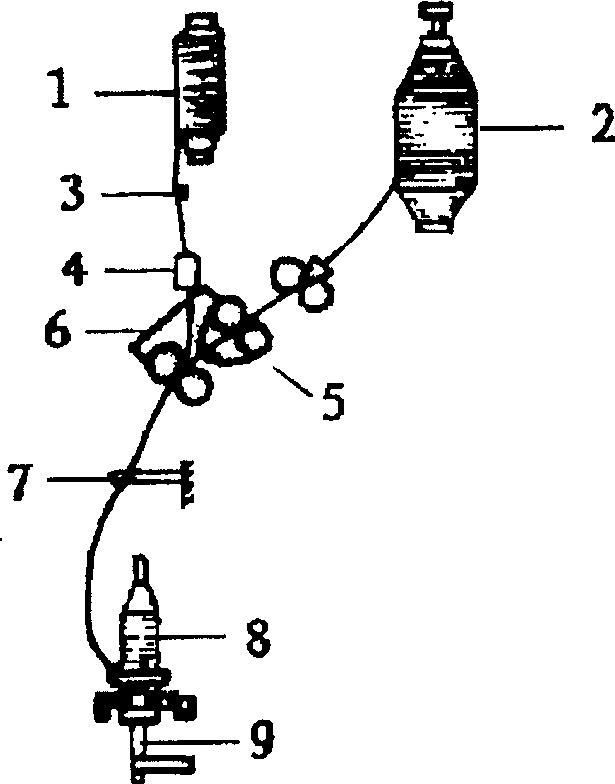

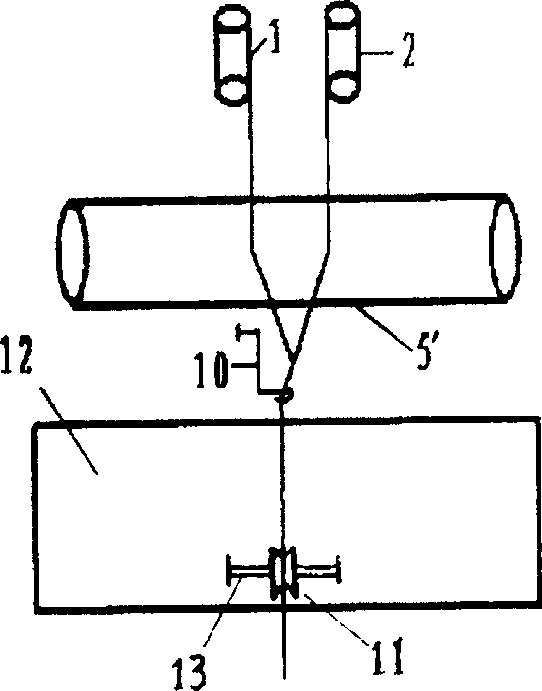

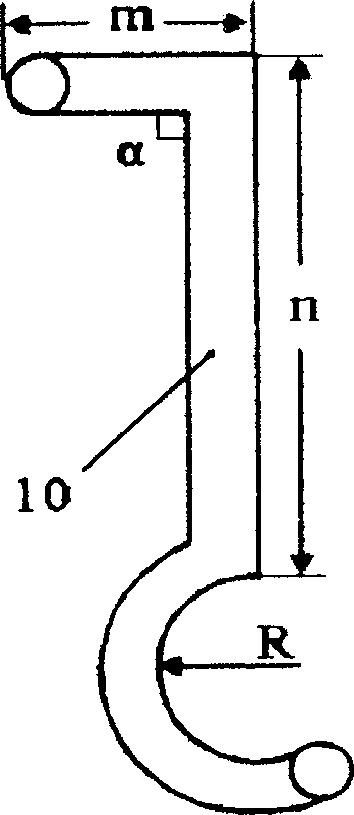

[0031] Such as figure 2 , image 3 , Figure 4 As shown, a kind of Sirofill spinning modulus compensation device of the present invention is characterized in that it is fixed on the modulus compensation hook 10 on the cradle 6 by the upper end and is fixed on the car panel 12 by the looper at both ends. The modulus adjustment groove block 11 on the upper circular shaft 13 is jointly formed. The modulus compensation hook 10 is fixed on the cradle 6 by the upper end, and its installation position is between the front roller 5' and the modulus adjustment groove block 11. The curvature radius R of the crotch at the lower end is 1-3 mm, and the rod is Inverted L shape, the length m of the upper rod is 40-50mm, the length n of the middle rod is 70-80mm, and the angle α between the upper rod and the middle rod is 90°. The front surface of the front roller 5' is determined by 10-30mm, and its upper and lower positions are determined by the bottom plane of the lower end hook being ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com