Electrochemical sensor of dissolved hydrogen sulfide in extreme exvironment

A high temperature and high pressure, hydrogen sulfide technology, applied in the field of sensors, achieves the effect of low detection limit, small size and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

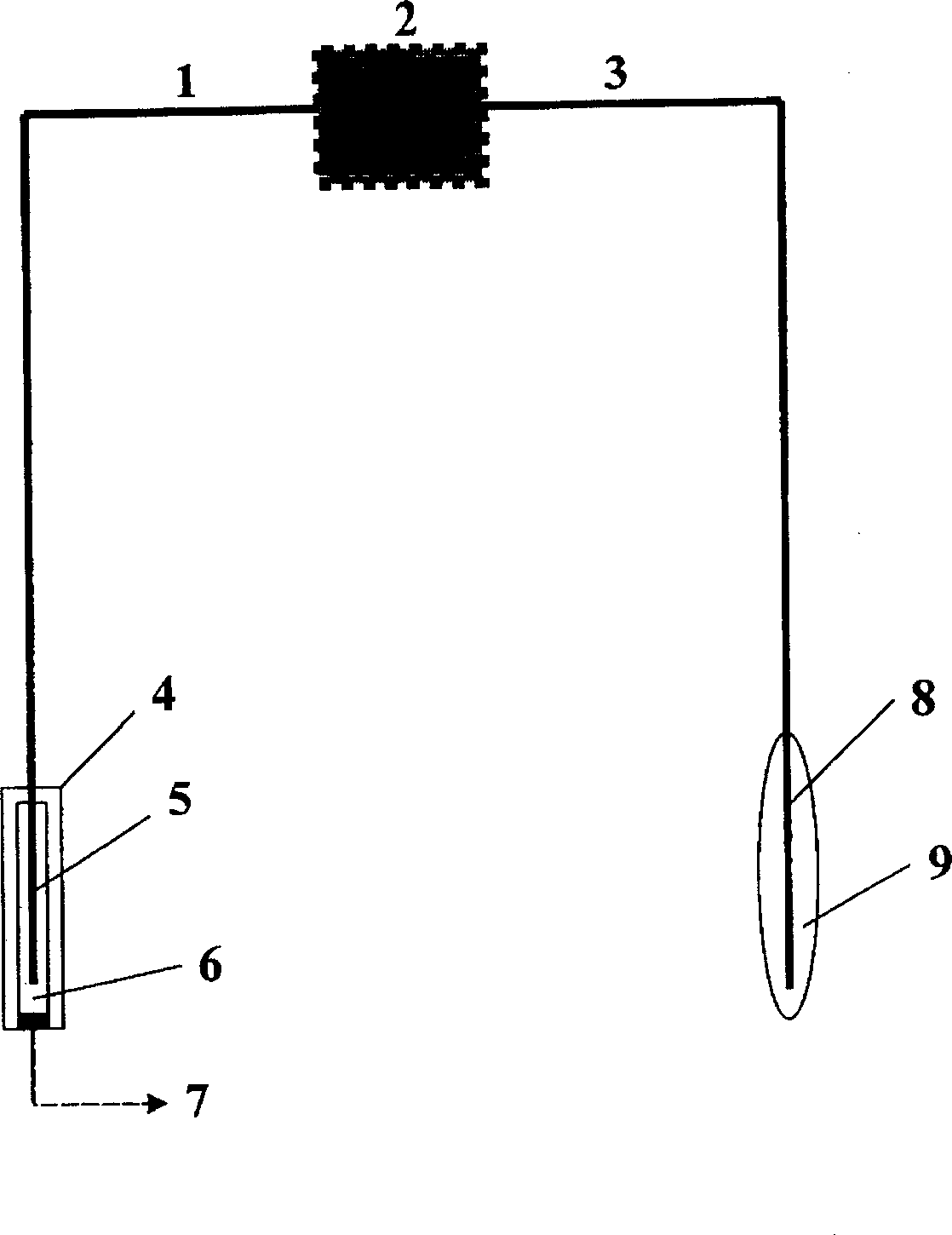

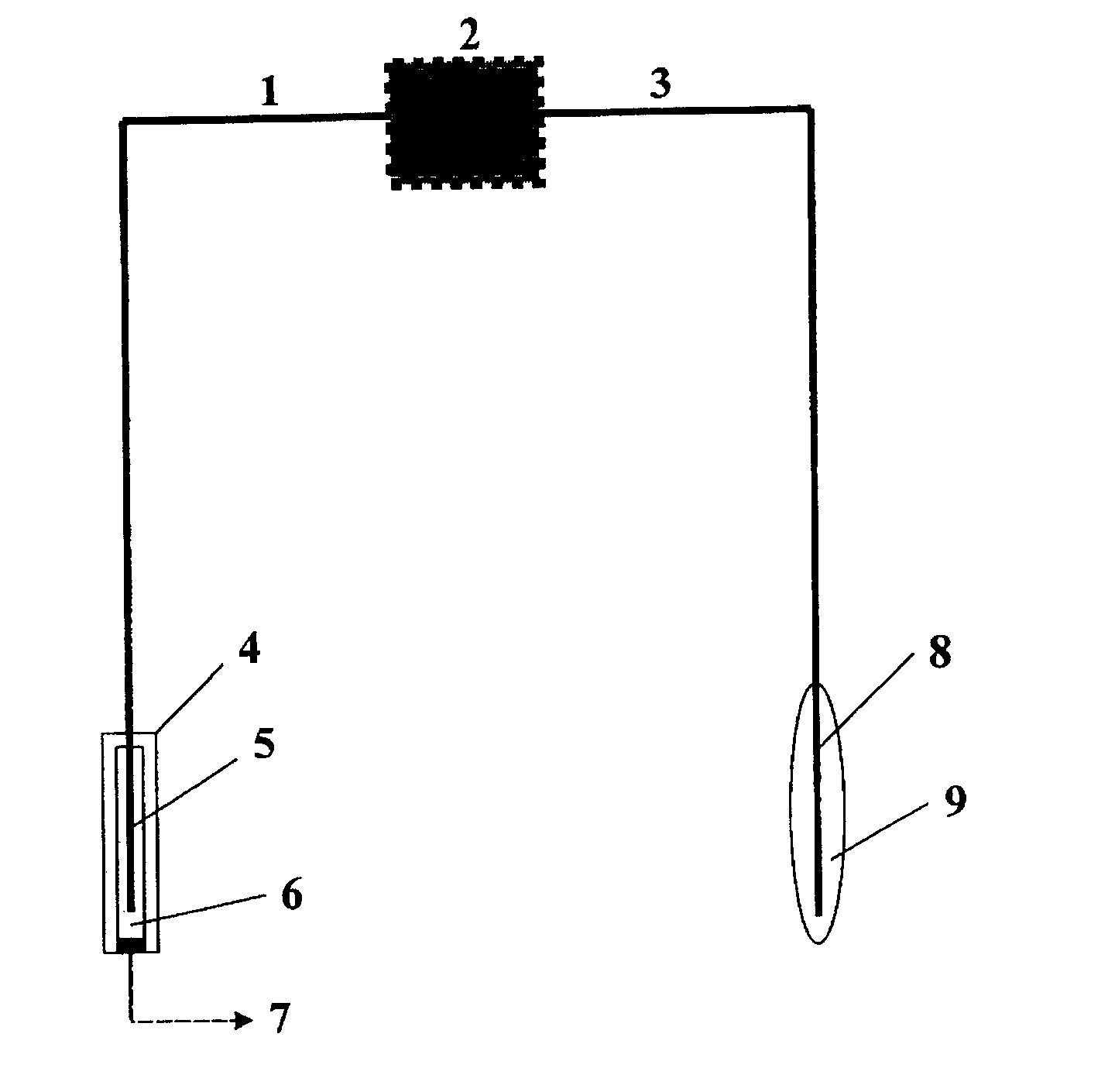

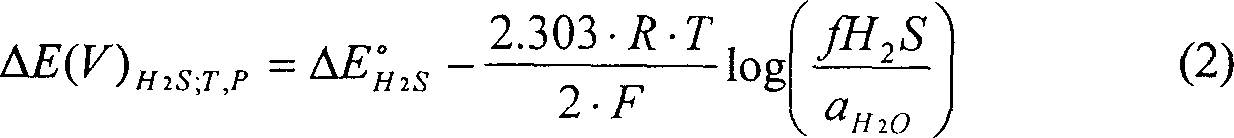

Method used

Image

Examples

preparation example Construction

[0009] The so-called Ag / Ag 2 The preparation method steps of S electrode are as follows:

[0010] 1) A polytetrafluoroethylene tube with an inner diameter of 0.3 to 2 mm is injected with silver-containing epoxy resin from one end, and a metal wire is inserted into the epoxy resin from the other end. The epoxy resin is cured at room temperature and polished with fine sandpaper.

[0011] 2) Hang the above-mentioned polytetrafluoroethylene tube vertically on the Ag + In the electroplating tank with KCN solution, connect it to the negative pole of the power supply, place a ring-shaped silver wire at the lower part of the above-mentioned PTFE tube 1-3 cm, connect it to the positive pole of the power supply, and pass a current of 8-12 μA for 30-60 minutes , take out the Teflon tube and rinse it with distilled water;

[0012] 3) Immerse the polytetrafluoroethylene tube in 0.1-0.5M concentration (NH 4 ) 2 S solution for 2 to 6 minutes, rinse with distilled water after taking it ou...

example 1

[0044] Example 1: Making Ag / Ag with silver-containing epoxy resin 2 S electrode

[0045] 1) A polytetrafluoroethylene tube with an inner diameter of 2 mm is injected with silver-containing epoxy resin from one end, and a silver wire is inserted into the epoxy resin from the other end. The epoxy resin is cured at room temperature and polished with fine sandpaper.

[0046] 2) Hang the above-mentioned polytetrafluoroethylene tube vertically on the Ag + In the electroplating tank with KCN solution, connect it to the negative pole of the power supply, place a ring-shaped silver wire at the lower part of the above-mentioned polytetrafluoroethylene tube 1 to 3 cm, connect it to the positive pole of the power supply, and pass a current of 10 μA for 45 minutes. The vinyl fluoride tube was taken out and rinsed with distilled water;

[0047] 3) Immerse the polytetrafluoroethylene tube in 0.3M (NH 4 ) 2 S solution for 2 minutes, then rinse with distilled water after removal.

[0048]...

example 2

[0049] Example 2: Making Ag / Ag with coated silver sheet 2 S electrode

[0050] 1) Take a silver wire with a diameter of 0.5 mm, and weld a piece of silver on one end thereof. The size of the silver sheet is: 0.25 mm in thickness, 6 mm in length, and 3 mm in width;

[0051] 2) Boil the end with the silver piece in acetone to remove organic impurities, then immerse in a nitric acid solution with a concentration of 0.5M, ultrasonically clean it, and clean it with distilled water after taking it out;

[0052] 3) Put the cleaned silver flakes in the concentration of 0.3M (NH 4 ) 2 Immerse in S solution for 2 minutes to form a layer of Ag on the surface of the silver sheet 2 S micro-membranes were rinsed again with distilled water.

[0053] 4) Dissolving the soluble polyimide in an organic solvent to prepare a solution with a concentration of 30%, coating the solution on the silver wire, and air-drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com