Field based process control system with auto-tuning

A process control and self-adjustment technology, applied in the direction of controllers with specific characteristics, general control systems, control/regulation systems, etc., can solve problems such as increasing algorithm complexity and adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

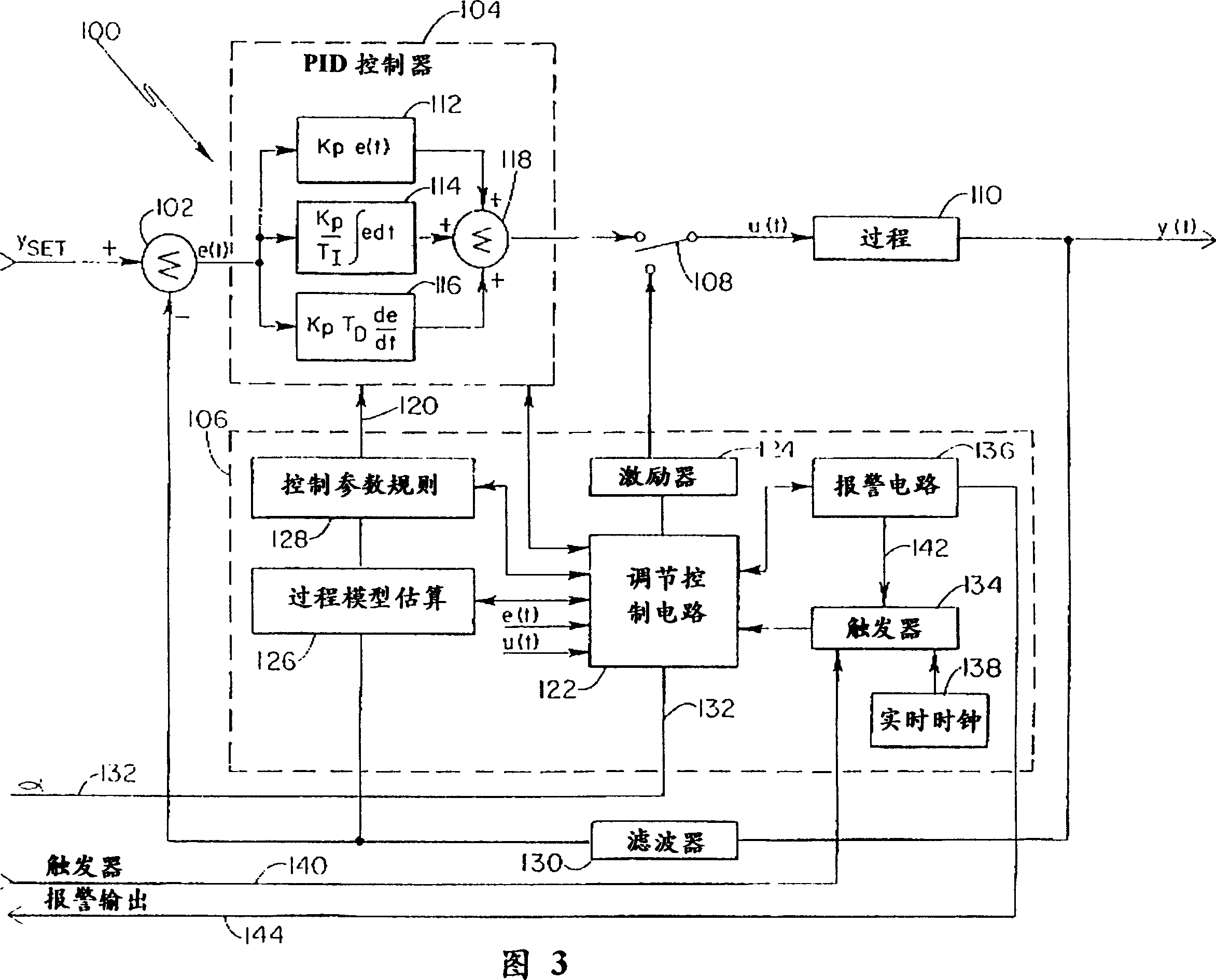

[0021] SUMMARY OF THE INVENTION The present invention is a process control system with robust self-regulating features and whose operation is computationally simple such that the system can be implemented in a low power field-installed control unit in a process control system.

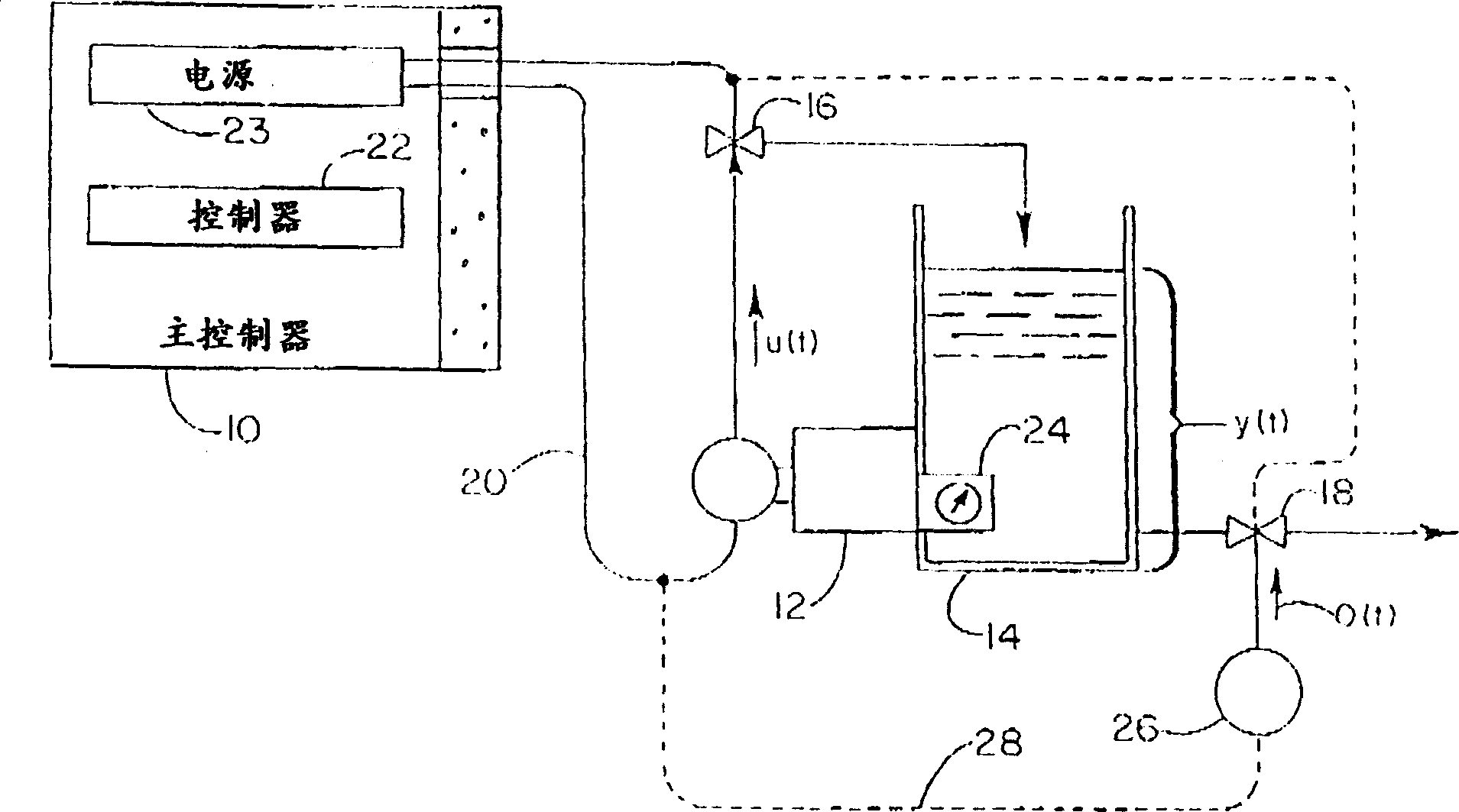

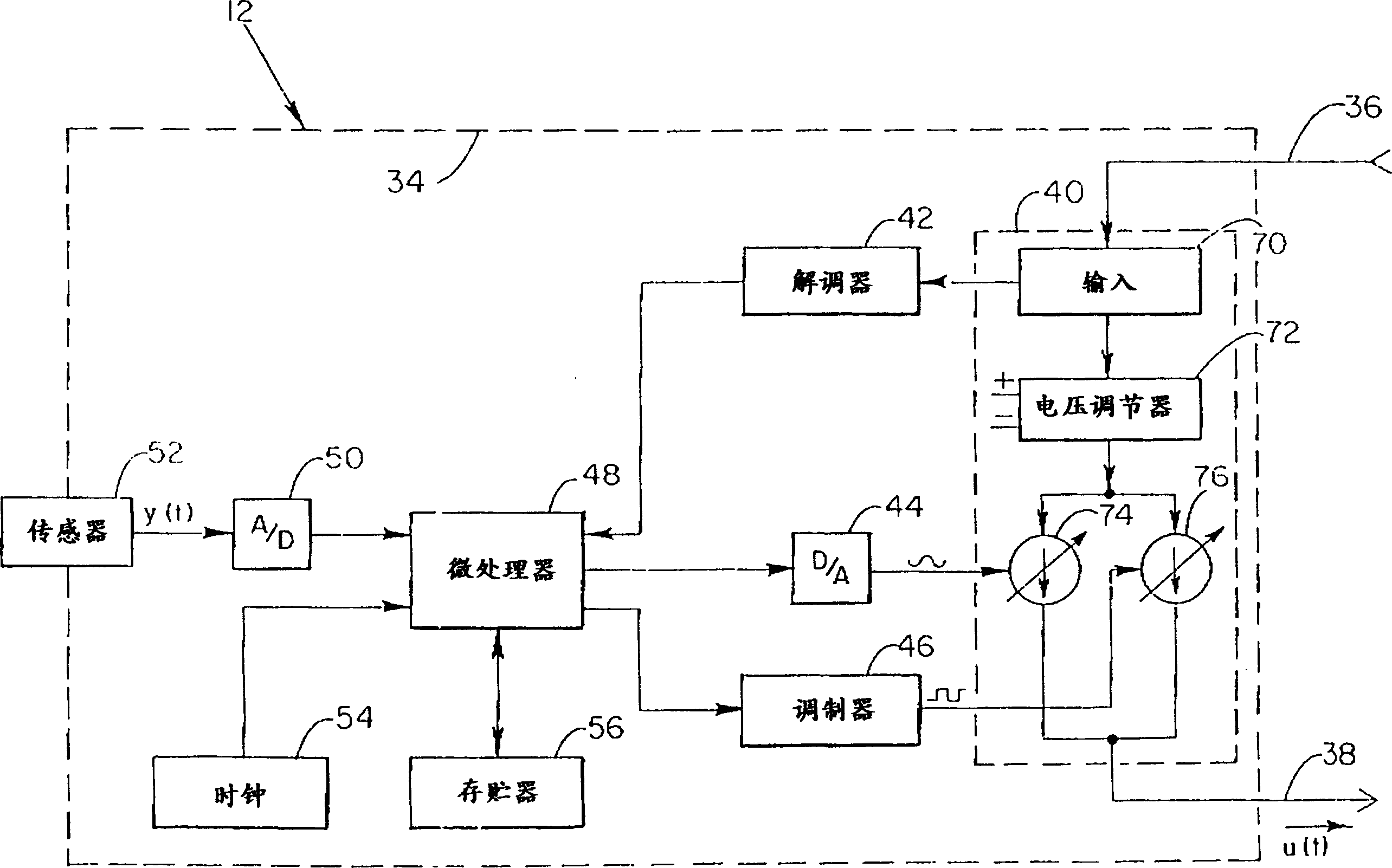

[0022] figure 1 It is a diagram of an embodiment of a process control system using the present invention. The process control system includes a master controller 10 , a transmitter 12 , a water tank 14 , an input valve 16 and an output valve 18 . The master controller 10 is connected to the transmitter 12 and the input valve 16 through a two-wire control loop 20 . Loop 20 may comprise a 4-20mA or 10-50mA current loop, eg, the loop allows host controller 10, transmitter 12 and valve 16 to communicate with each other by varying the current level in the loop. In alternative embodiments, the master controller 10, the transmitter 12 and the valve 16 communicate with each other on a loop with varying volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com