Objective lens driving device

A technology of driving device and objective lens, applied in beam guiding device, configuration/installation of head, instrument, etc., can solve the problems of difficult magnetic circuit and increased number of parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The preferred embodiments of the present invention will be described below in conjunction with the drawings.

[0052] First, the first embodiment of the objective lens driving device of the present invention will be explained.

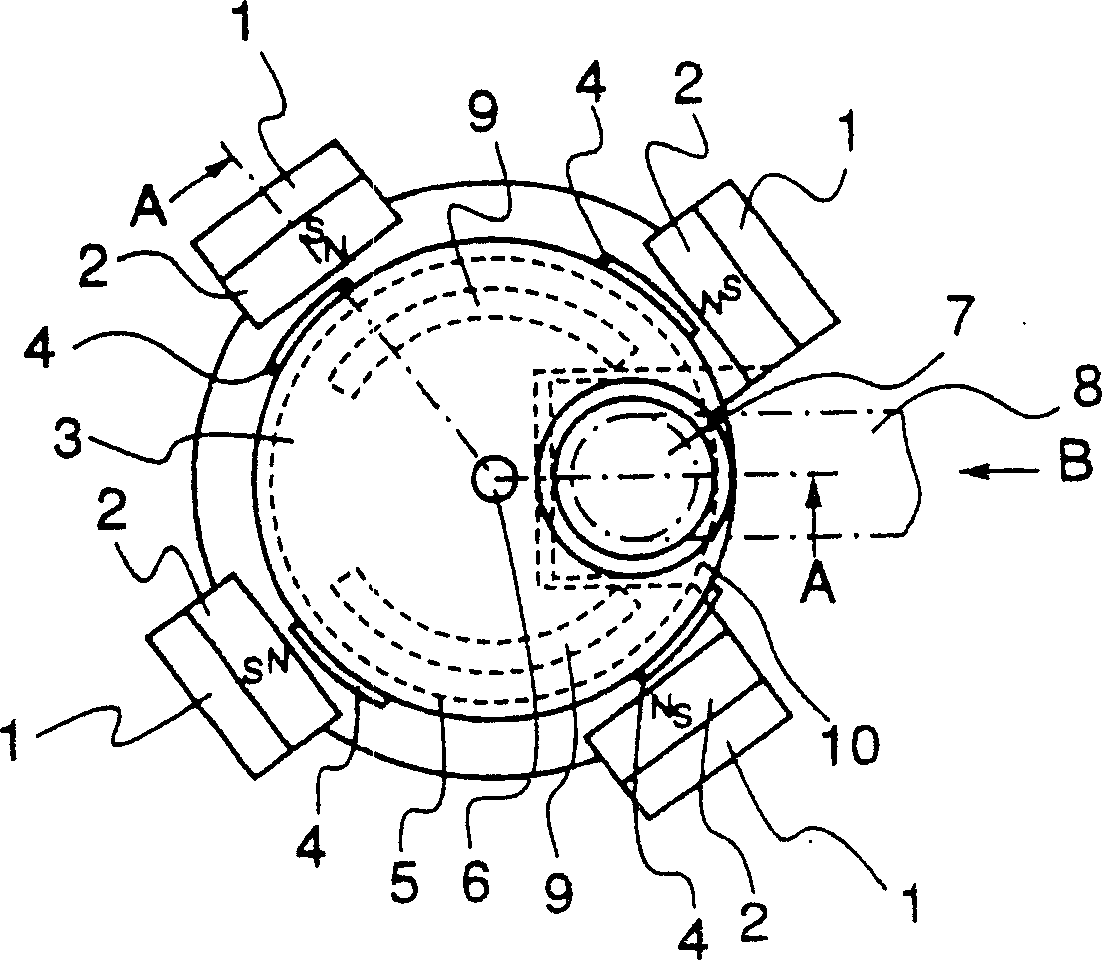

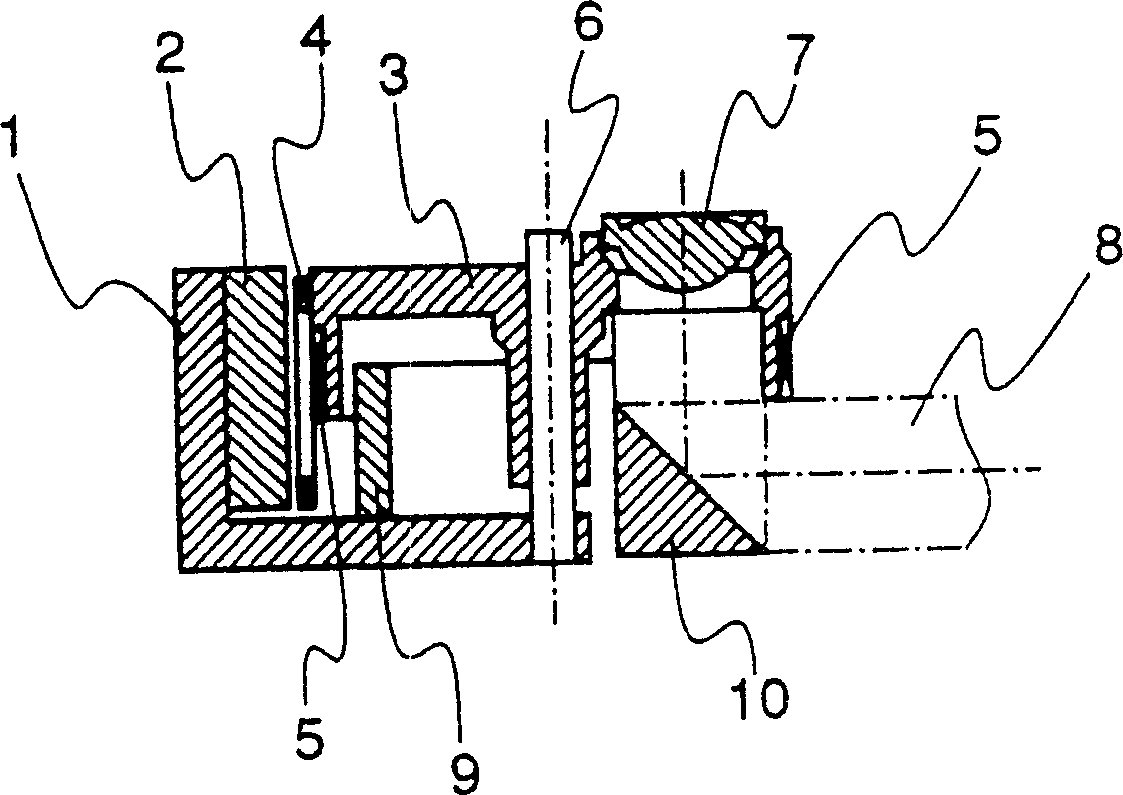

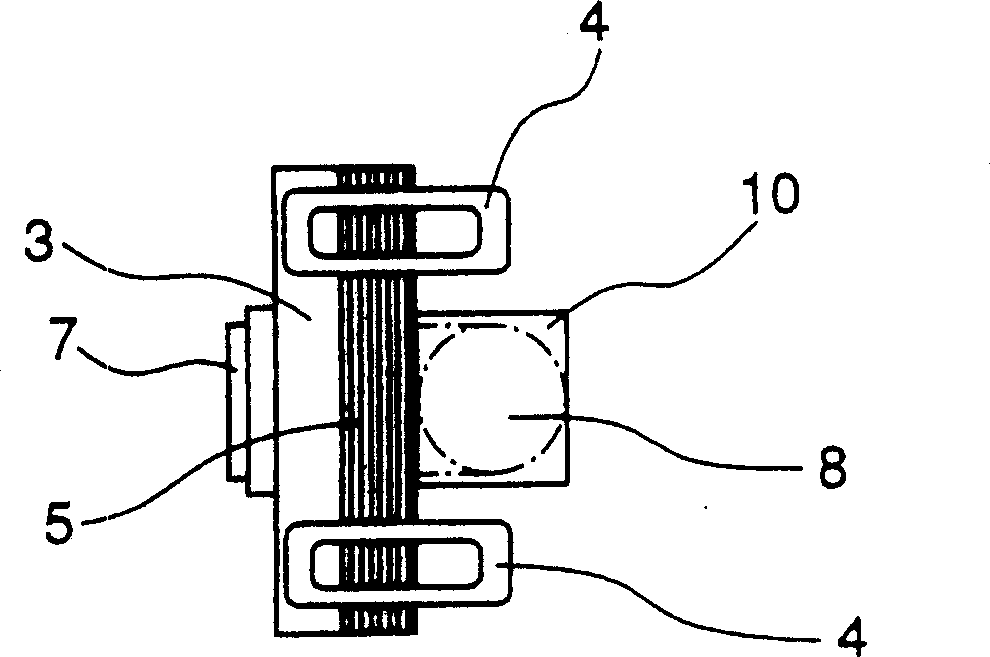

[0053] figure 1 An explanatory diagram showing the structure of the first embodiment of the objective lens driving device of the present invention. figure 2 Means figure 1 A cross-sectional view along the line A-A in the middle. image 3 Means from figure 1 The view of the objective lens driving device when viewed in the direction of arrow B.

[0054] in figure 1 There is an objective lens 7 in the lens holder 3, which is supported and guided by a sliding shaft 6, and the sliding shaft 6 is slidably and rotatably arranged to be substantially parallel to the optical axis direction of the objective lens 7. The focusing coil 5 is wound around the outer circumference of the lens holder 3, and the tracking coil 4 is coaxially arranged on the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com