Fuel injection valve

A fuel injection valve, fuel injection device technology, applied in the direction of fuel injection device, special fuel injection device, charging system, etc., can solve the problems of system temperature fluctuation, high cost, high processing cost, and achieve precise working mode, inclined Small tendencies, easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

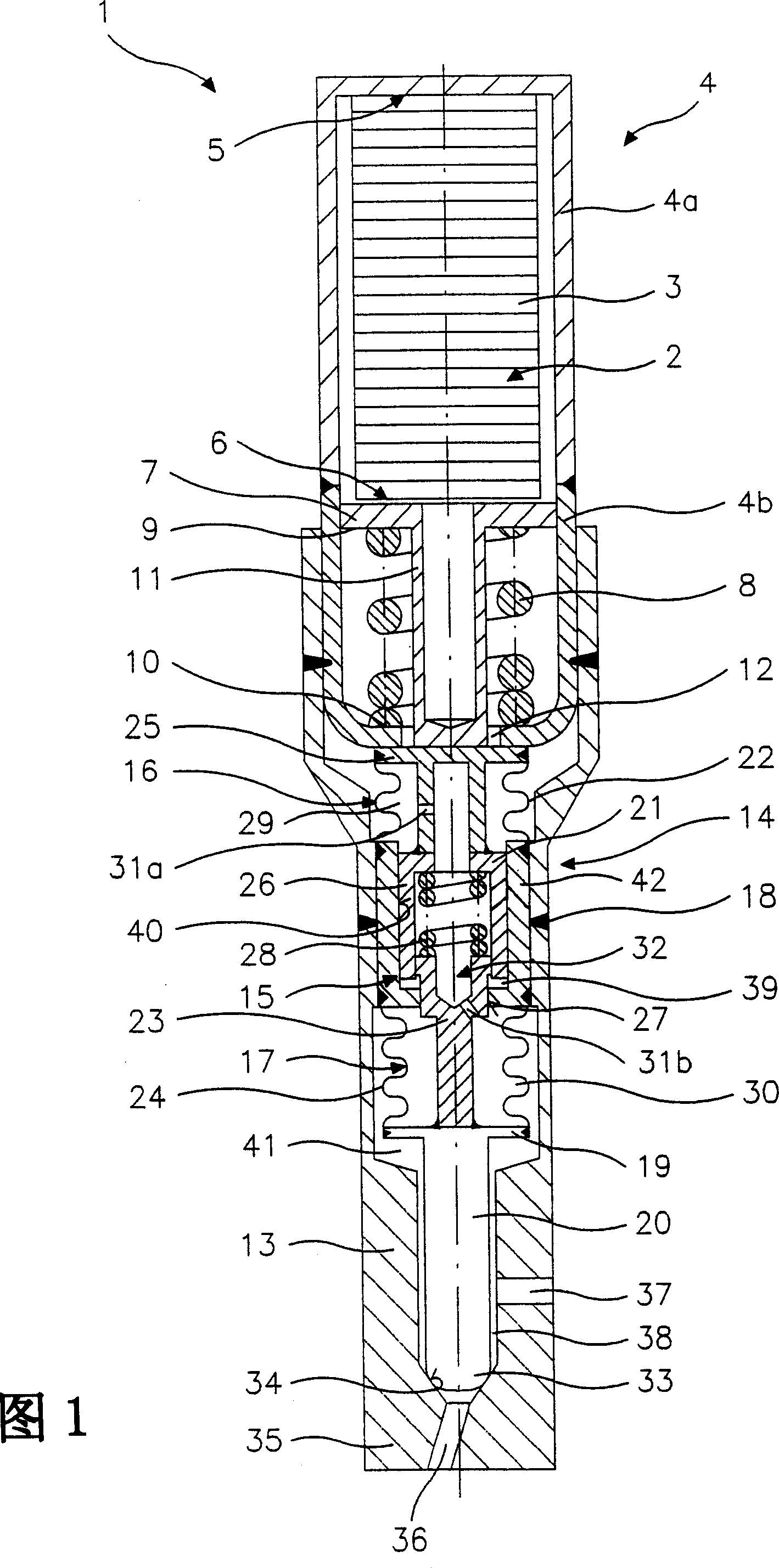

[0026] FIG. 1 shows an exemplary embodiment of a fuel injector 1 according to the invention in an axial sectional view. This is an inwardly opening fuel injector 1 . It is used in particular for the direct injection of fuel into the combustion chamber of a hybrid compression forced ignition internal combustion engine.

[0027] An actuator 2 , which is preferably designed as a disk-shaped piezoelectric or magnetostrictive element 3 , is accommodated in a two-part actuator housing 4 . The actuator 2 is surrounded at a first end face 5 in a sleeve-like manner by a first actuator housing part 4 a with a cover part and rests with a second end face 6 on an actuator flange 7 . A preload spring 8 rests with a first end 9 on the actuator flange 7 and is surrounded by a second actuator housing part 4 b in a sleeve-like manner, the second end 10 of the preload spring 8 It is supported on the second actuator housing part. The two actuator housing parts 4a, 4b are welded together, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com