New connector for formwork assembling

A technology for formwork assembly and connectors, which is applied to the joints of formwork/formwork/work frame, preparation of building components on site, construction, etc. It can solve the problem that the quality of formwork assembly is not easy to guarantee, the construction site is easy to be damaged, and the impact on concrete Pouring quality and other issues, achieve fast locking and disassembly speed, ensure pouring quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

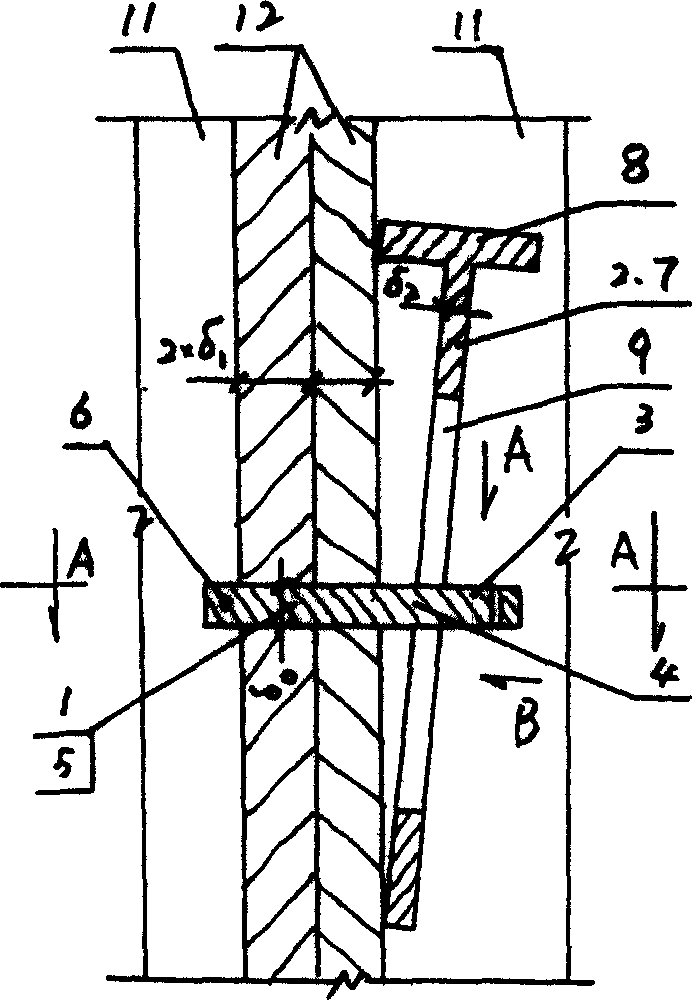

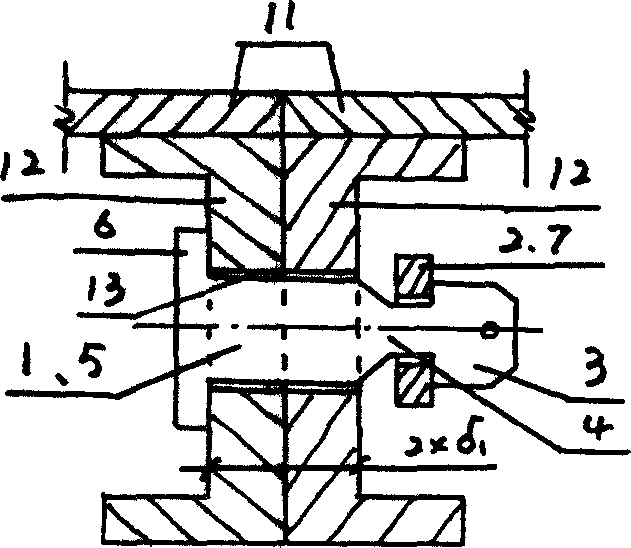

[0016] Detailed description with the attached drawings;

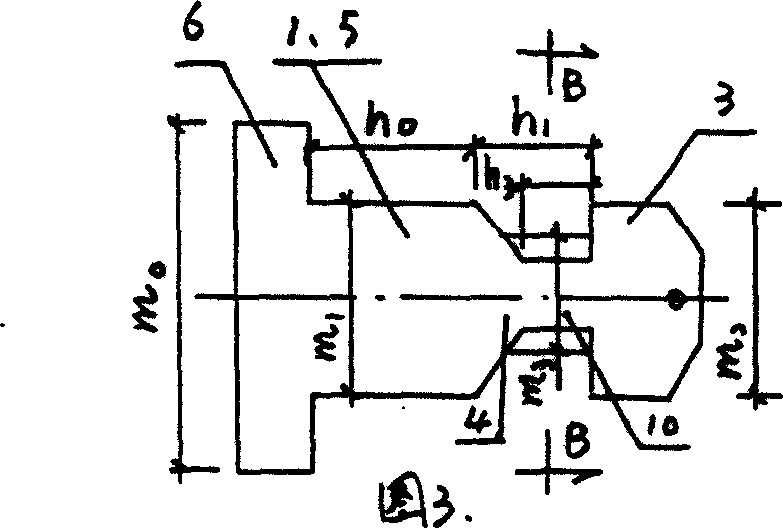

[0017] As shown in Figures 1, 2, 3, 6, and 9, the height of the plug 5 is h 0 It is basically equal to the thickness δ of the frame 12 of the template 11 1 Double the height of the shoulder 4 h 1 Equal to the height h of the outer edge of the tip 8 2 1 / 2~2 / 3; the width of the plug 5 m 1 According to the different structure of the bolt tail 6, it can be equal to or smaller than the width m of the bolt tail 6. 0 , And the thickness of the bolt tail 6 can be equal to or greater than the thickness δ of the bolt body 5 0 ; The structural dimensions of the bolt head 3 and the strip hole 9 are matched to each other, and should be able to ensure that the wedge body 7 of the T-shaped spring wedge plate 2 is conveniently and reliably seated and wedged;

[0018] As shown in Figures 1, 3, and 5, the strip hole 9 is located at the center of the wedge body 7 but at the tail end. The width S of the hole must be greater than the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com