Device for providing shutting force for plastic injection machine for shoe manufacture

A technology of injection molding machine and closing force, which is applied in the direction of fluid pressure actuators, mechanical equipment, servo motors, etc., and can solve the problem of large land occupation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

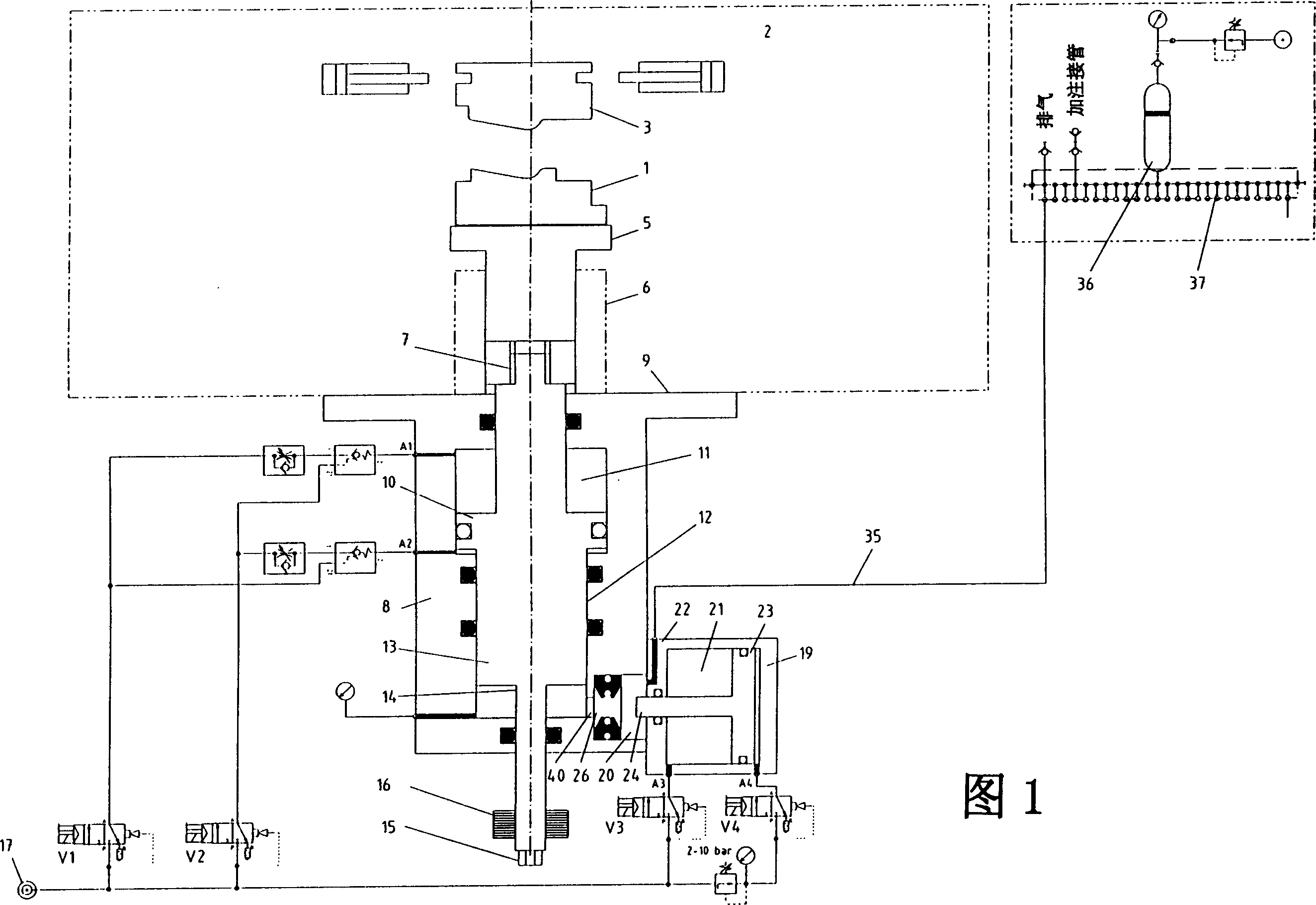

[0020] 1 schematically depicts a drive for the vertical movement of a bottom mold 1 in a forming station 2 on a circular table of an injection molding machine for the manufacture of shoes, not shown. The forming station 2 comprises, in addition to the bottom mold 1 , not shown side mold parts and a displacer 3 . The bottom mold 1 and the ejector 3 and the side molds form a cavity for the manufacture of shoe soles. In this figure the apparatus for producing the outermost layer of the sole is depicted.

[0021] The bottom form 1 is mounted on a lift table 5 which is guided vertically in a lift table guide rail 6 . The piston rod 7 of a first piston-cylinder arrangement, referred to below as the die cylinder 8 , acts on the lifting table 5 from below, which is connected at 9 to the forming station.

[0022] The piston rod 7 is assigned a piston 10 which can be acted on both sides with compressed air via the compressed air lines A1 and A2. With the aid of compressed air, the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com